Thin Section Four Point Contact Ball Bearings

Outer Diameter: 225-870mm, Weight: 5.1-470kg

2. Type: QJ, QJF

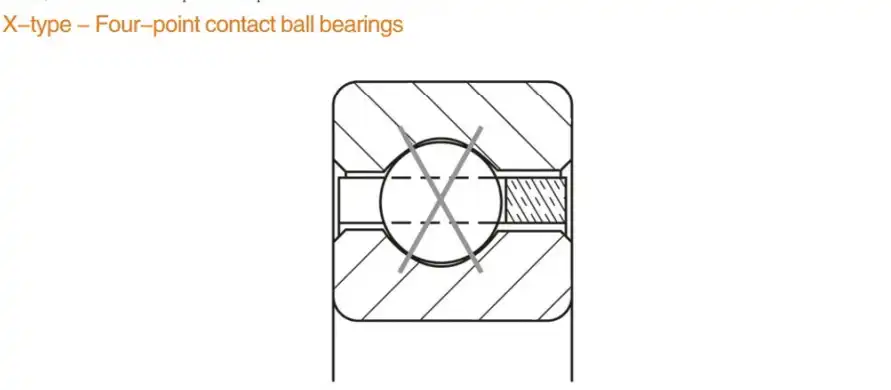

3. Feature: Four point contact ball bearings are separable bearings, in which, type QJ0000 has two piece inner ring, type QJF0000 has two piece outer rings, their contact angle are both 35°. When carrying pure radial loads, each ball cotacts with rings ar four point, and they are two point contact under pure axial loads. The bearings can carry axial loads in two directions and certain moment loads, and have the features of single row and double row angular contact ball bearings. They only can work normally in high speed when two point contact is formed.

4. Cage: Brass or aluminium soild cages are exactly suitbale for four point contact ball bearings.

5. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

Thin Section Four Point Contact Ball Bearings

Thin Section Four Point Contact Ball Bearings are precision-engineered components designed for applications requiring compact, lightweight, and high-performance bearings. These bearings are known for their ability to handle both radial and axial loads in a single direction, making them ideal for high-precision machinery where space and weight are critical constraints. Unlike traditional bearings, thin section designs offer reduced dimensions while maintaining robust performance, making them suitable for aerospace, medical, robotics, automotive, and consumer electronics applications.

Why Choose CHG Bearing?

CHG Bearing is a leading manufacturer and supplier of Thin Section Four Point Contact Ball Bearings, known for delivering high-quality, reliable, and customized bearing solutions. Here’s why you should partner with us:

- Customization and Solutions: We provide tailored solutions for various working conditions, ensuring our bearings meet specific operational demands.

- 30 Years of Industry Experience: With three decades of expertise, we have a proven track record of working with numerous large enterprises.

- Innovative and Certified: Our company holds over 50 invention patents and complies with ISO9001 quality management and ISO14001 environmental management standards.

Technical Specifications

| Specification | Details |

|---|---|

| Type | Thin Section Four Point Contact Ball Bearing |

| Material | High-quality chrome steel / stainless steel / ceramic |

| Dimension Range | Customizable based on application needs |

| Load Capacity | High radial and axial load capacity |

| Temperature Range | Suitable for various operating temperatures |

| Precision Grade | P0/ P5 /P6 /P4 /P2 |

| Certificates | ISO9001, ISO14001, Occupational health and safety management system certification |

Thin Section Four Point Contact Ball Bearings and Their Benefits

Thin Section Four Point Contact Ball Bearings offer several advantages:

- Space Efficiency: Their compact design allows for integration into tight spaces without sacrificing performance.

- Load Handling: Capable of supporting both radial and axial loads, providing versatile performance.

- Reduced Weight: Lightweight construction aids in reducing the overall weight of the machinery.

- Enhanced Precision: Ideal for applications requiring high precision and reliability.

Applications

These bearings are utilized in a variety of high-demand sectors:

- Aerospace: Essential for aircraft and satellite systems where space and weight constraints are critical.

- Medical Equipment: Used in surgical instruments and diagnostic tools where precision and reliability are paramount.

- Automation and Robotics: Integral in industrial robots and automation systems that demand high efficiency and lightweight components.

- Automotive Industry: Found in electric vehicles and high-performance automotive parts.

- Consumer Electronics: Applied in motion systems of precision instruments and high-end electronic devices.

Installation Guide

- Preparation: Ensure the installation area is clean and free from debris.

- Alignment: Align the bearing with the mounting surface to avoid misalignment issues.

- Mounting: Secure the bearing using appropriate tools and methods to ensure a tight fit.

- Verification: Check for any signs of improper installation such as noise or vibration.

Maintenance and Care

To ensure longevity and optimal performance:

- Regular Inspections: Periodically check for signs of wear or damage.

- Lubrication: Maintain proper lubrication to minimize friction and wear.

- Cleanliness: Keep the bearing and surrounding area clean to prevent contamination.

- Proper Storage: Store bearings in a dry, cool environment when not in use.

FAQ

Q: What are the key benefits of using Thin Section Four Point Contact Ball Bearings?

A: They offer compact size, reduced weight, and the ability to handle both radial and axial loads efficiently.

Q: Can these bearings be customized for specific applications?

A: Yes, CHG Bearing provides customized solutions to meet unique application requirements.

Q: What industries commonly use the product?

A: Aerospace, medical equipment, automation and robotics, automotive, and consumer electronics.

Customer Reviews

John D., Aerospace Engineer: “CHG Bearing's thin section bearings have proven to be exceptionally reliable in our aerospace applications. Their performance exceeds our expectations!”

Lisa M., Robotics Specialist: “The customization options provided by CHG Bearing allowed us to integrate their bearings seamlessly into our robotic systems. Excellent quality and service.”

Contact Us

For more information about thin section four point contact ball bearings or to request a quote, please contact us at sale@chg-bearing.com. Our team is ready to assist with your specific needs and provide expert solutions for your bearing requirements.

| HKAA series | |||||||

| Type | (inch/mm) Dimension | N | Weight | ||||

| Basic Cap. | Kg | ||||||

| d | D | L1 | L2 | Cor | Cr | ||

| HKAA010C | 1 | 1.375 | 1.142 | 1.236 | 1290 | 670 | 0.012 |

| 25.4 | 34.925 | 29 | 31.4 | ||||

| HKAA015C | 1.5 | 1.875 | 1.642 | 1.736 | 1780 | 800 | 0.018 |

| 38.1 | 47.625 | 41.7 | 44.1 | ||||

| HKA series | |||||||

| Type | (inch/mm) Dimension | N | Weight | ||||

| Basic Cap. | Kg | ||||||

| d | D | L1 | L2 | Cor | Cr | ||

| HKA020C | 2 | 2.5 | 2.186 | 2.134 | 3020 | 1420 | 0.048 |

| 50.8 | 63.5 | 55.5 | 58.8 | ||||

| HKA025C | 2.5 | 3 | 2.686 | 2.814 | 3690 | 1600 | 0.059 |

| 63.5 | 76.2 | 68.2 | 71.5 | ||||

| HKA030C | 3 | 3.5 | 3.186 | 3.314 | 4400 | 1820 | 0.068 |

| 76.2 | 88.9 | 80.9 | 84.2 | ||||

| HKA035C | 3.5 | 4 | 3.686 | 3.814 | 5070 | 2000 | 0.082 |

| 88.9 | 101.6 | 93.6 | 96.9 | ||||

| HKA040C | 4 | 4.5 | 4.186 | 4.314 | 5730 | 2130 | 0.09 |

| 101.6 | 114.3 | 106.3 | 109.6 | ||||

| HKA042C | 4.25 | 4.75 | 4.436 | 4.564 | 6090 | 2220 | 0.095 |

| 107.95 | 120.65 | 112.7 | 115.9 | ||||

| HKA045C | 4.5 | 5 | 4.686 | 4.814 | 6400 | 2310 | 0.1 |

| 114.3 | 127 | 119 | 122.3 | ||||

| HKA047C | 4.75 | 5.25 | 4.936 | 5.064 | 6760 | 2400 | 0.104 |

| 120.65 | 133.35 | 125.4 | 128.6 | ||||

| HKA050C | 5 | 5.5 | 5.186 | 5.314 | 7070 | 2490 | 0.109 |

| 127 | 139.7 | 131.7 | 135 | ||||

| HKA060C | 6 | 6.5 | 6.186 | 6.314 | 8450 | 2800 | 0.13 |

| 152.4 | 165.1 | 157.1 | 160.4 | ||||

| HKA065C | 6.5 | 7 | 6.686 | 6.814 | 9110 | 2930 | 0.14 |

| 165.1 | 1.778 | 169.8 | 173.1 | ||||

| HKA070C | 7 | 7.5 | 7.186 | 7.314 | 9780 | 3070 | 0.15 |

| 177.8 | 190.5 | 182.5 | 185.8 | ||||

| HKA075C | 7.5 | 8 | 7.686 | 7.814 | 10450 | 3200 | 0.16 |

| 190.5 | 203.2 | 195.2 | 198.5 | ||||

| HKA080C | 8 | 8.5 | 8.186 | 8.314 | 11110 | 3330 | 0.172 |

| 203.2 | 215.9 | 207.9 | 211.2 | ||||

| HKA090C | 9 | 9.5 | 9.186 | 9.314 | 12490 | 3600 | 0.2 |

| 228.6 | 241.3 | 233.3 | 236.6 | ||||

| HKA100C | 10 | 10.5 | 10.186 | 10.314 | 13820 | 3870 | 0.227 |

| 254 | 266.7 | 258.7 | 262 | ||||

| HKA110C | 11 | 11.5 | 11.186 | 11.314 | 15160 | 4130 | 0.236 |

| 279.4 | 292.1 | 284.1 | 287.4 | ||||

| HKA120C | 12 | 12.5 | 12.186 | 12.314 | 16540 | 4360 | 0.254 |

| 304.8 | 317.5 | 309.5 | 312.8 | ||||

| HKB series | |||||||

| Type | (inch/mm) Dimension | N | Weight | ||||

| Basic Cap. | Kg | ||||||

| d | D | L1 | L2 | Cor | Cr | ||

| HKB020C | 2 | 2.625 | 2.231 | 2.393 | 4130 | 2000 | 0.073 |

| 50.8 | 66.675 | 56.7 | 60.8 | ||||

| HKB025C | 2.5 | 3.125 | 2.731 | 2.893 | 5070 | 2310 | 0.091 |

| 63.5 | 79.375 | 69.4 | 73.5 | ||||

| HKB030C | 3 | 3.625 | 3.231 | 3.393 | 5960 | 2580 | 0.109 |

| 76.2 | 92.075 | 82.1 | 86.2 | ||||

| HKB035C | 3.5 | 4.125 | 3.731 | 3.893 | 6850 | 2800 | 0.125 |

| 88.9 | 104.775 | 94.8 | 98.9 | ||||

| HKB040C | 4 | 4.625 | 4.432 | 4.393 | 7780 | 3070 | 0.14 |

| 101.6 | 117.475 | 107.5 | 111.6 | ||||

| HKB042C | 4.2 | 4.875 | 4.481 | 4.643 | 8130 | 3160 | 0.147 |

| 107.95 | 123.825 | 113.8 | 117.9 | ||||

| HKB045C | 4.5 | 5.125 | 4.731 | 4.893 | 8670 | 3290 | 0.16 |

| 114.3 | 130.175 | 120.2 | 124.3 | ||||

| HKB047C | 4.75 | 5.375 | 4.981 | 5.143 | 9020 | 3380 | 0.163 |

| 120.65 | 136.525 | 126.6 | 130.6 | ||||

| HKB050C | 5 | 5.625 | 5.231 | 5.393 | 9560 | 3510 | 0.172 |

| 127 | 142.875 | 132.9 | 137 | ||||

| HKB055C | 5.5 | 6.125 | 5.731 | 5.893 | 10490 | 3730 | 0.186 |

| 139.7 | 155.575 | 145.6 | 149.7 | ||||

| HKB060C | 6 | 6.625 | 6.231 | 6.393 | 11380 | 3960 | 0.205 |

| 152.4 | 168.275 | 158.3 | 162.4 | ||||

| HKB065C | 6.5 | 7.125 | 6.731 | 6.893 | 12270 | 4130 | 0.216 |

| 165.1 | 180.975 | 171 | 175.1 | ||||

| HKB070C | 7 | 7.625 | 7.231 | 7.393 | 13200 | 4360 | 0.232 |

| 177.8 | 193.675 | 183.7 | 187.8 | ||||

| HKB075C | 7.5 | 8.125 | 7.731 | 7.893 | 14090 | 4530 | 0.25 |

| 190.5 | 206.375 | 196.4 | 200.5 | ||||

| HKB080C | 8 | 8.625 | 8.231 | 8.393 | 14980 | 4670 | 0.262 |

| 203.2 | 219.075 | 209.1 | 213.2 | ||||

| HKB090C | 9 | 9.625 | 9.231 | 9.393 | 16800 | 5110 | 0.3 |

| 228.6 | 244.475 | 234.5 | 238.6 | ||||

| HKB100C | 10 | 10.625 | 10.231 | 10.393 | 18620 | 5470 | 0.331 |

| 254 | 269.875 | 259.9 | 264 | ||||

| HKB110C | 11 | 11.625 | 11.231 | 11.393 | 20400 | 5820 | 0.36 |

| 279.4 | 295.275 | 285.3 | 289.4 | ||||

| HKB120C | 12 | 12.625 | 12.231 | 12.393 | 22230 | 6180 | 0.39 |

| 304.8 | 320.675 | 310.7 | 314.8 | ||||

| HKB140C | 14 | 14.625 | 14.231 | 14.393 | 25830 | 6800 | 0.476 |

| 355.6 | 371.475 | 361.5 | 365.6 | ||||

| HKB160C | 16 | 16.625 | 16.231 | 16.393 | 29430 | 7420 | 0.544 |

| 406.4 | 422.275 | 412.3 | 416.4 | ||||

| HKB180C | 18 | 18.625 | 18.231 | 18.393 | 33070 | 8050 | 0.612 |

| 457.2 | 473.075 | 463.1 | 467.2 | ||||

| HKB200C | 20 | 20.625 | 20.231 | 20.393 | 36670 | 8620 | 0.68 |

| 508 | 523.875 | 513.9 | 518 | ||||

| HKC series | |||||||

| Type | (inch/mm) Dimension | N | Weight | ||||

| Basic Cap. | Kg | ||||||

| d | D | L1 | L2 | Cor | Cr | ||

| HKC040C | 4 | 4.75 | 4.277 | 4.473 | 9330 | 3910 | 0.204 |

| 101.6 | 120.65 | 108.6 | 113.6 | ||||

| HKC042C | 4.25 | 5 | 4.527 | 4.723 | 9780 | 4090 | 0.213 |

| 107.95 | 127 | 115 | 120 | ||||

| HKC045C | 4.5 | 5.25 | 4.777 | 4.973 | 10400 | 4220 | 0.225 |

| 114.3 | 133.35 | 121.3 | 126.3 | ||||

| HKC047C | 4.75 | 5 | 5.027 | 5.223 | 10930 | 4360 | 0.235 |

| 120.65 | 139.7 | 127.7 | 132.7 | ||||

| HKC050C | 5 | 5.75 | 5.277 | 5.473 | 11510 | 4490 | 0.263 |

| 127 | 146.05 | 134 | 139 | ||||

| HKC055C | 5.5 | 6.25 | 5.777 | 5.973 | 12580 | 4800 | 0.268 |

| 139.7 | 158.75 | 146.7 | 151.7 | ||||

| HKC060C | 6 | 6.75 | 6.277 | 6.473 | 13650 | 5070 | 0.295 |

| 152.4 | 171.45 | 159.4 | 164.4 | ||||

| HKC065C | 6.5 | 7.25 | 6.777 | 6.973 | 14710 | 5330 | 0.312 |

| 165.1 | 184.15 | 172.1 | 177.1 | ||||

| HKC070C | 7 | 7.75 | 7.277 | 7.473 | 15780 | 5560 | 0.34 |

| 177.8 | 196.85 | 184.4 | 189.8 | ||||

| HKC075C | 7.5 | 8.25 | 7.777 | 7.973 | 16850 | 5820 | 0.36 |

| 190.5 | 209.55 | 197.5 | 202.5 | ||||

| HKC080C | 8 | 8.75 | 8.277 | 8.473 | 17910 | 6050 | 0.387 |

| 203.2 | 222.25 | 210.2 | 215.2 | ||||

| HKC090C | 9 | 9.75 | 9.277 | 9.473 | 20050 | 6530 | 0.45 |

| 228.6 | 247.65 | 235.6 | 240.6 | ||||

| HKC100C | 10 | 10.75 | 10.277 | 10.473 | 22180 | 6980 | 0.481 |

| 254 | 273.05 | 261 | 266 | ||||

| HKC110C | 11 | 11.75 | 11.277 | 11.473 | 24310 | 7420 | 0.526 |

| 279.4 | 298.45 | 286.4 | 291.4 | ||||

| HKC120C | 12 | 12.75 | 12.277 | 12.473 | 26450 | 7870 | 0.567 |

| 304.8 | 323.85 | 311.8 | 316.8 | ||||

| HKC140C | 14 | 14.75 | 14.277 | 14.473 | 30720 | 8670 | 0.689 |

| 355.6 | 374.65 | 362.6 | 367.6 | ||||

| HKC160C | 16 | 16.75 | 16.277 | 16.473 | 35030 | 9470 | 0.785 |

| 406.4 | 425.45 | 413.4 | 418.4 | ||||

| HKC180C | 18 | 18.75 | 18.277 | 18.473 | 39290 | 10220 | 0.88 |

| 457.2 | 476.25 | 464.2 | 469.2 | ||||

| HKC200C | 20 | 20.75 | 20.277 | 20.473 | 43560 | 10980 | 0.98 |

| 508 | 527.05 | 515 | 520 | ||||

| HKD series | |||||||

| Type | (inch/mm) Dimension | N | Weight | ||||

| Basic Cap. | Kg | ||||||

| d | D | L1 | L2 | Cor | Cr | ||

| HKD040C | 4 | 5 | 4.37 | 4.63 | 13690 | 6270 | 0.366 |

| 101.6 | 127 | 111 | 117.6 | ||||

| HKD042C | 4.25 | 5.25 | 4.62 | 4.88 | 14180 | 6400 | 0.386 |

| 107.95 | 133.35 | 117.3 | 124 | ||||

| HKD045C | 4.5 | 5.5 | 4.87 | 5.13 | 15200 | 6710 | 0.405 |

| 114.3 | 139.7 | 123.7 | 130.3 | ||||

| HKD047C | 4.75 | 5.75 | 5.12 | 5.38 | 15690 | 6850 | 0.426 |

| 120.65 | 146.05 | 130 | 136.7 | ||||

| HKD050C | 5 | 6 | 5.37 | 5.63 | 16710 | 7160 | 0.454 |

| 127 | 152.4 | 136.4 | 143 | ||||

| HKD055C | 5.5 | 6.5 | 5.87 | 6.13 | 18230 | 7560 | 0.485 |

| 139.7 | 165.1 | 149.1 | 155.7 | ||||

| HKD060C | 6 | 7 | 6.37 | 6.63 | 19780 | 8000 | 0.526 |

| 152.4 | 177.8 | 161.8 | 168.4 | ||||

| HKD065C | 6.5 | 7.5 | 6.87 | 7.13 | 21290 | 8400 | 0.566 |

| 165.1 | 190.5 | 174.5 | 181.1 | ||||

| HKD070C | 7 | 8 | 7.37 | 7.63 | 22800 | 8800 | 0.606 |

| 177.8 | 203.2 | 187.2 | 193.8 | ||||

| HKD075C | 7.5 | 8.5 | 7.87 | 8.13 | 24310 | 9160 | 0.65 |

| 190.5 | 215.9 | 199.9 | 206.5 | ||||

| HKD080C | 8 | 9 | 8.37 | 8.63 | 25830 | 9560 | 0.694 |

| 203.2 | 228.6 | 212.6 | 219.2 | ||||

| HKD090C | 9 | 10 | 9.37 | 9.63 | 28890 | 10310 | 0.78 |

| 228.6 | 254 | 238 | 244.6 | ||||

| HKD100C | 10 | 11 | 10.37 | 10.63 | 31920 | 10980 | 0.853 |

| 254 | 279.4 | 263.4 | 270 | ||||

| HKD110C | 11 | 12 | 11.37 | 11.63 | 34980 | 11690 | 0.934 |

| 279.4 | 304.8 | 288.8 | 295.4 | ||||

| HKD120C | 12 | 13 | 12.37 | 12.63 | 38010 | 12360 | 1.02 |

| 304.8 | 330.2 | 314.2 | 320.8 | ||||

| HKD140C | 14 | 15 | 14.37 | 14.63 | 44090 | 13650 | 1.24 |

| 355.6 | 381 | 365 | 371.6 | ||||

| HKD160C | 16 | 17 | 16.37 | 16.63 | 50180 | 14890 | 1.41 |

| 406.4 | 431.8 | 415.8 | 422.4 | ||||

| HKD180C | 18 | 19 | 18.37 | 18.63 | 56230 | 16050 | 1.58 |

| 457.2 | 482.6 | 466.6 | 473.2 | ||||

| HKD200C | 20 | 21 | 20.37 | 20.63 | 62320 | 17200 | 1.75 |

| 508 | 533.4 | 517.4 | 524 | ||||

| HKF series | |||||||

| Type | (inch/mm) Dimension | N | Weight | ||||

| Basic Cap. | Kg | ||||||

| d | D | L1 | L2 | Cor | Cr | ||

| HKF040C | 4 | 5.5 | 4.555 | 4.945 | 23830 | 12130 | 0.875 |

| 101.6 | 139.7 | 115.7 | 125.6 | ||||

| HKF042C | 4.25 | 5.75 | 4.805 | 5.195 | 25070 | 12580 | 0.93 |

| 107.95 | 146.05 | 122 | 132 | ||||

| HKF045C | 4.5 | 6 | 5.055 | 5.445 | 26360 | 12980 | 0.975 |

| 114.3 | 152.4 | 128.4 | 138.3 | ||||

| HKF047C | 4.75 | 6.25 | 5.305 | 5.695 | 27600 | 13380 | 1.04 |

| 120.65 | 158.75 | 134.7 | 144.7 | ||||

| HKF050C | 5 | 6.5 | 5.555 | 5.945 | 28850 | 13780 | 1.09 |

| 127 | 165.1 | 141.1 | 151 | ||||

| HKF055C | 5.5 | 7 | 6.055 | 6.445 | 31340 | 14580 | 1.18 |

| 139.7 | 177.8 | 153.8 | 163.7 | ||||

| HKF060C | 6 | 7.5 | 6.555 | 6.945 | 33870 | 15340 | 1.24 |

| 152.4 | 190.5 | 166.5 | 176.4 | ||||

| HKF065C | 6.5 | 8 | 7.055 | 7.445 | 36360 | 16090 | 1.35 |

| 165.1 | 203.2 | 179.2 | 189.1 | ||||

| HKF070C | 7 | 8.5 | 7.555 | 7.945 | 38890 | 16850 | 1.45 |

| 177.8 | 215.9 | 191.9 | 201.8 | ||||

| HKF075C | 7.5 | 9 | 8.055 | 8.445 | 41380 | 17560 | 1.56 |

| 190.5 | 228.6 | 204.6 | 214.5 | ||||

| HKF080C | 8 | 9.5 | 8.555 | 8.945 | 43920 | 18230 | 1.66 |

| 203.2 | 241.3 | 217.3 | 227.2 | ||||

| HKF090C | 9 | 10.5 | 9.555 | 9.945 | 48900 | 19600 | 1.81 |

| 228.6 | 266.7 | 242.7 | 252.6 | ||||

| HKF100C | 10 | 11.5 | 10.555 | 10.945 | 53920 | 20940 | 2.02 |

| 254 | 292.1 | 268.1 | 278 | ||||

| HKF110C | 11 | 12.5 | 11.555 | 11.945 | 58940 | 22230 | 2.18 |

| 279.4 | 317.5 | 293.5 | 303.4 | ||||

| HKF120C | 12 | 13.5 | 12.555 | 12.945 | 63960 | 23470 | 2.38 |

| 304.8 | 342.9 | 318.9 | 328.3 | ||||

| HKF140C | 14 | 15.5 | 14.555 | 14.945 | 74010 | 25830 | 2.72 |

| 355.6 | 393.7 | 369.7 | 379.6 | ||||

| HKF160C | 16 | 17.5 | 16.555 | 16.945 | 84010 | 28140 | 3.22 |

| 406.4 | 444.5 | 420.5 | 430.4 | ||||

| HKF180C | 18 | 19.5 | 18.555 | 18.945 | 94060 | 30320 | 3.58 |

| 457.2 | 495.3 | 471.3 | 481.2 | ||||

| HKF200C | 20 | 21.5 | 20.555 | 20.945 | 104100 | 32450 | 4.04 |

| 508 | 546.1 | 522.1 | 532 | ||||

| HKG series | |||||||

| Type | (inch/mm) Dimension | N | Weight | ||||

| Basic Cap. | Kg | ||||||

| d | D | L1 | L2 | Cor | Cr | ||

| HKG040C | 4 | 6 | 4.742 | 5.258 | 36490 | 200000 | 1.65 |

| 101.6 | 152.4 | 120.4 | 133.6 | ||||

| HKG042C | 4.25 | 6.25 | 4.992 | 5.508 | 36490 | 20000 | 1.75 |

| 107.95 | 158.75 | 126.8 | 139.9 | ||||

| HKG045C | 4.5 | 6.5 | 5.242 | 5.758 | 38940 | 20900 | 1.81 |

| 114.3 | 165.1 | 133.1 | 146.3 | ||||

| HKG047C | 4.75 | 6.75 | 5.492 | 6.008 | 41340 | 21740 | 1.91 |

| 120.65 | 171.45 | 139.5 | 152.6 | ||||

| HKG050C | 5 | 7 | 5.742 | 6.258 | 43780 | 22580 | 2.02 |

| 127 | 177.8 | 145.8 | 159 | ||||

| HKG055C | 5.5 | 7.5 | 6.242 | 6.758 | 46230 | 23430 | 2.17 |

| 139.7 | 190.5 | 158.5 | 171.7 | ||||

| HKG060C | 6 | 8 | 6.742 | 7.258 | 51070 | 25030 | 2.31 |

| 152.4 | 203.2 | 171.2 | 184.4 | ||||

| HKG065C | 6.5 | 8.5 | 7.242 | 7.758 | 53520 | 25830 | 2.47 |

| 165.1 | 215.9 | 183.9 | 197.1 | ||||

| HKG070C | 7 | 9 | 7.742 | 8.258 | 58360 | 27380 | 2.67 |

| 177.8 | 228.6 | 196.6 | 209.8 | ||||

| HKG075C | 7.5 | 9.5 | 8.242 | 8.758 | 60810 | 28140 | 2.83 |

| 190.5 | 241.3 | 209.3 | 222.5 | ||||

| HKG080C | 8 | 10 | 8.742 | 9.258 | 65650 | 29600 | 3 |

| 203.2 | 254 | 222 | 235.2 | ||||

| HKG090C | 9 | 11 | 9.742 | 10.258 | 72990 | 31780 | 3.3 |

| 228.6 | 279.4 | 247.4 | 260.6 | ||||

| HKG100C | 10 | 12 | 10.742 | 11.258 | 80280 | 33870 | 3.65 |

| 254 | 304.8 | 272.8 | 286 | ||||

| HKG110C | 11 | 13 | 11.742 | 12.258 | 87570 | 35870 | 3.96 |

| 279.4 | 330.2 | 11.742 | 12.258 | ||||

| HKG120C | 12 | 14 | 12.742 | 13.258 | 94860 | 37830 | 4.32 |

| 304.8 | 355.6 | 323.6 | 336.8 | ||||

| HKG140C | 14 | 16 | 14.742 | 15.258 | 109440 | 41610 | 4.96 |

| 355.6 | 406.4 | 374.4 | 387.6 | ||||

| HKG160C | 16 | 18 | 16.742 | 17.258 | 124060 | 45250 | 5.65 |

| 406.4 | 457.2 | 425.2 | 438.4 | ||||

| HKG180C | 18 | 20 | 18.742 | 19.258 | 138640 | 48720 | 6.28 |

| 457.2 | 508 | 476 | 489.2 | ||||

| HKG200C | 20 | 22 | 20.742 | 21.258 | 153220 | 52100 | 7.53 |

| 508 | 558.8 | 526.8 | 540 | ||||

YOU MAY LIKE

VIEW MOREThin Section Angular Contact Bearings

VIEW MOREThin Section Angular Contact Bearings VIEW MOREType C Thin Section Bearing

VIEW MOREType C Thin Section Bearing VIEW MOREType A Thin Section Bearing

VIEW MOREType A Thin Section Bearing VIEW MOREThin Section Deep Groove Ball Bearings

VIEW MOREThin Section Deep Groove Ball Bearings VIEW MOREMetric Thin Section Bearings

VIEW MOREMetric Thin Section Bearings VIEW MOREPrecision Angular Contact Ball Bearing

VIEW MOREPrecision Angular Contact Ball Bearing VIEW MOREPrecision Deep Groove Ball Bearings

VIEW MOREPrecision Deep Groove Ball Bearings VIEW MOREType X Thin Section Bearing

VIEW MOREType X Thin Section Bearing