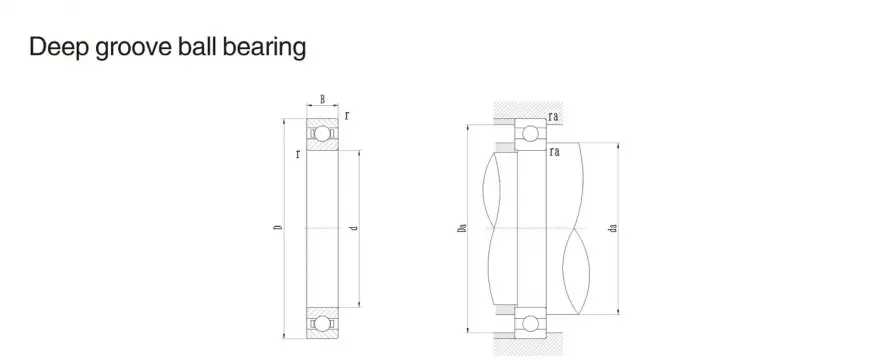

Precision Deep Groove Ball Bearings

2. Sizes: 618 Series

Inner Diameter: 100-950mm, Outer Diameter: 125-1150mm

Width: 13-90mm, Weight: 0.31-190kg

619 Seies

Inner Diameter: 100-950mm, Outer Diameter: 140-1250mm

Width: 20-132mm, Weight: 0.96-390kg

3. Feature: small friction coefficient, high limiting speeds, simple structure, low cost, and high manufacturing precision.

4. Application: It has various sizes and structures, and is used in precision instruments, low noise motors, automobiles, motorcycles and general machinery industries, and a kind of bearing with most applications in the machinery industry.

5. Cage: A stamped ribbon cage is commonly machined as the solid cage; sometimes the nylon cage can also be used

What is a Precision Deep Groove Ball Bearing?

High-performance Precision Deep Groove Ball Bearings are made for applications that demand high levels of precision, dependability, and durability. These bearings can support both radial and axial loads in a wide range of applications thanks to their straightforward yet efficient design. They are essential components in high-precision machinery due to their ability to function smoothly and effectively under a variety of conditions.

CHG Bearing: Your Trusted Precision Deep Groove Ball Bearings Manufacturer

We are proud to be a leading manufacturer and supplier of Precision Deep Groove Ball Bearings at CHG Bearing. We offer the following with over 30 years of industry expertise:

- Solutions and Customization: To ensure that your bearings perform at their best and last for a long time, we offer specialized solutions tailored to specific working conditions.

- Extensive Knowledge of the Industry: Our capacity to produce high-quality goods is exemplified by the numerous large corporations with whom we have worked for a long time.

- Excellence in Innovation: We are committed to quality and innovation, and we hold over 50 invention patents. Our dedication to excellence can be seen in our products' certifications under the ISO9001 quality management and ISO14001 environmental management systems.

Please contact us at sale@chg-bearing.com for additional information or a quote.

Technical Specifications

| Specification | Details |

|---|---|

| Type | Deep Groove Ball Bearing |

| Material | High-grade steel, ceramic options |

| Bore Diameter | Customizable |

| Outer Diameter | Customizable |

| Width | Customizable |

| Load Capacity | High radial and axial load |

| Temperature Range | -40°C to +150°C |

| Speed Rating | High-speed capabilities |

| Seal Type | Open, Shielded, or Sealed |

Benefits of Precision Deep Groove Ball Bearings

It offer several key benefits:

- High Precision: Designed with minimal runout and optimal performance in mind, it is ideal for precise applications.

- Durability: Constructed to resist wear and withstand heavy loads, resulting in a longer service life.

- Versatility: Suitable for a wide range of uses, including consumer electronics, the automotive industry, and aerospace.

- Simple to Maintain: Minimal upkeep, reducing downtime and costs associated with maintenance.

Applications

Precision Deep Groove Ball Bearings are widely used in diverse industries, including:

- Aerospace: For high-precision components in aircraft and satellites.

- Medical Equipment: In surgical instruments and diagnostic machinery where precision and reliability are critical.

- Automation and Robotics: In industrial robots and automation systems for improved efficiency and performance.

- Automotive Industry: In electric vehicles and high-performance automotive parts.

- Consumer Electronics: In motion systems for high-end electronic products and precision instruments.

Installation Guide

1.Preparation: Make certain that there are no contaminants in the bearing and housing.

2.Alignment: To avoid issues with misalignment, align the bearing with the housing correctly.

3.Insertion: Using appropriate tools, gently press the bearing into place without applying too much force.

4.Securing: Utilize appropriate retaining rings or locking mechanisms to secure the bearing.

5.Lubrication: To ensure smooth operation and lessen friction, use the recommended lubricant.

Maintenance and Care

To ensure the longevity and optimal performance of your products:

- Regular checkups: Bearings should be replaced as necessary and checked for signs of wear or damage.

- Suitable Lubrication: To avoid excessive wear and tear, maintain the appropriate level of lubrication.

- A healthy environment: To prevent contamination, keep the bearings and surrounding areas clean.

- Beware of Overworking: To avoid premature failure, adhere to the recommended load limits.

FAQ

1. What makes Precision Deep Groove Ball Bearings different from standard bearings?

Bearings are manufactured to tighter tolerances and higher standards of accuracy, making them suitable for applications where precision is critical.

2. Can these bearings handle both radial and axial loads?

Yes, it designed to support both radial and axial loads, making them versatile for various applications.

3. What is the typical service life of these bearings?

With proper maintenance and correct usage, the products can provide a long service life. The exact duration will depend on application conditions and load factors.

4. Are customization options available for these bearings?

Yes, CHG Bearing offers customization options to meet specific requirements related to bore size, outer diameter, and other specifications.

5. How can I get technical support for my bearings?

For technical support, please contact us at sale@chg-bearing.com, and our experts will assist you with your queries.

Customer Reviews

- “CHG Bearing’s Precision Deep Groove Ball Bearings have been crucial in our high-precision applications. The quality and reliability are unmatched.” – Alex J., Aerospace Engineer

- “Exceptional performance and support. CHG Bearing’s customization options perfectly met our needs.” – Maria L., Robotics Specialist

Contact Us

Please contact us for additional information or to discuss your specific requirements: sale@chg-bearing.com. Take your applications to new heights with the precision and dependability of CHG Bearing's products.

| Dimensions | Basic Load Rating | Part number | Weight | Installation Size | Limiting Speed | |||||||

| mm | kN | kg | mm | r/min | ||||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | ||

| 100 | 125 | 13 | 1 | 19.6 | 21.2 | 61820 | 0.31 | 105 | 120 | 1 | 4800 | 5700 |

| 110 | 140 | 16 | 1 | 28.1 | 30.7 | 61822 | 0.61 | 115 | 135 | 1 | 4300 | 5100 |

| 120 | 150 | 16 | 1 | 29 | 33 | 61824 | 0.66 | 125 | 145 | 1 | 4000 | 4700 |

| 130 | 165 | 18 | 1.1 | 36.9 | 41.2 | 61826 | 0.94 | 136.5 | 158.5 | 1 | 3600 | 4300 |

| 140 | 175 | 18 | 1.1 | 38.2 | 44.4 | 61828 | 1 | 146.5 | 168.5 | 1 | 3400 | 4000 |

| 150 | 190 | 20 | 1.1 | 49.1 | 58.5 | 61830 | 1.15 | 156.6 | 183.5 | 1 | 3000 | 3600 |

| 160 | 200 | 20 | 1.1 | 48.5 | 61 | 61832 | 1.23 | 166.5 | 193.5 | 1 | 2800 | 3400 |

| 170 | 215 | 22 | 1.1 | 61.5 | 78 | 61834 | 1.9 | 176.5 | 208.5 | 1 | 2600 | 3200 |

| 180 | 225 | 22 | 1.1 | 62.3 | 78.5 | 61836 | 1.72 | 186.5 | 218.5 | 1 | 2400 | 3000 |

| 190 | 240 | 24 | 1.5 | 75.1 | 93.5 | 61838 | 2.53 | 198 | 232 | 1.5 | 2200 | 2800 |

| 200 | 250 | 24 | 1.5 | 74 | 98 | 61840 | 2.67 | 208 | 242 | 1.5 | 2200 | 2800 |

| 220 | 270 | 24 | 1.5 | 76.5 | 97.8 | 61844 | 2.9 | 228 | 262 | 1.5 | 1900 | 2400 |

| 240 | 300 | 28 | 2 | 83.5 | 108 | 61848 | 4.48 | 249 | 291 | 2 | 1800 | 2200 |

| 260 | 320 | 28 | 2 | 101 | 148 | 61852 | 4.84 | 269 | 311 | 2 | 1700 | 2000 |

| 280 | 350 | 33 | 2 | 133 | 191 | 61856 | 7.2 | 289 | 341 | 2 | 1600 | 1900 |

| Dimensions | Basic Load Rating | Part number | Weight | Installation Size | Limiting Speed | |||||||

| mm | kN | kg | mm | r/min | ||||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | ||

| 300 | 380 | 38 | 2.1 | 166 | 233 | 61860 | 10.3 | 311 | 369 | 2 | 1400 | 1700 |

| 320 | 400 | 38 | 2.1 | 168 | 244 | 61864 | 10.8 | 331 | 389 | 2 | 1300 | 1600 |

| 340 | 420 | 38 | 2.1 | 175 | 265 | 61868 | 11.5 | 351 | 409 | 2 | 1200 | 1500 |

| 360 | 440 | 38 | 2.1 | 192 | 290 | 61872 | 11.8 | 371 | 429 | 2 | 1100 | 1400 |

| 380 | 480 | 46 | 2.1 | 238 | 375 | 61876 | 19.5 | 391 | 469 | 2 | 1000 | 1300 |

| 400 | 500 | 46 | 2.1 | 241 | 390 | 61880 | 20.5 | 411 | 489 | 2 | 1000 | 1300 |

| 420 | 520 | 46 | 2.1 | 245 | 410 | 61884 | 21.4 | 431 | 509 | 2 | 950 | 1200 |

| 440 | 540 | 46 | 2.1 | 249 | 425 | 61888 | 22.3 | 451 | 529 | 2 | 900 | 1100 |

| 460 | 580 | 56 | 3 | 310 | 550 | 61892 | 34.3 | 473 | 567 | 2.5 | 900 | 1100 |

| 480 | 600 | 56 | 3 | 315 | 575 | 61896 | 35.4 | 493 | 587 | 2.5 | 850 | 1000 |

| 500 | 620 | 56 | 3 | 320 | 600 | 618/500 | 37.2 | 513 | 607 | 2.5 | 800 | 950 |

| 530 | 650 | 56 | 3 | 325 | 625 | 618/530 | 39.8 | 543 | 637 | 2.5 | 750 | 900 |

| 560 | 680 | 56 | 3 | 330 | 650 | 618/560 | 41.5 | 573 | 667 | 2.5 | 700 | 850 |

| 600 | 730 | 60 | 3 | 355 | 735 | 618/600 | 50.9 | 613 | 717 | 2.5 | 670 | 800 |

| Dimensions | Basic Load Rating | Part number | Weight | Installation Size | Limiting Speed | |||||||

| mm | kN | kg | mm | r/min | ||||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | ||

| 630 | 780 | 69 | 4 | 420 | 890 | 618/630 | 71.3 | 646 | 767 | 3 | 630 | 750 |

| 670 | 820 | 69 | 4 | 435 | 965 | 618/670 | 75.4 | 686 | 807 | 3 | 560 | 670 |

| 710 | 870 | 74 | 4 | 480 | 1100 | 618/710 | 92.6 | 726 | 854 | 3 | 530 | 630 |

| 750 | 920 | 78 | 5 | 525 | 1260 | 618/750 | 110 | 770 | 900 | 4 | 500 | 600 |

| 800 | 980 | 82 | 5 | 530 | 1310 | 618/800 | 132 | 820 | 960 | 4 | 450 | 530 |

| 850 | 1030 | 82 | 5 | 559 | 1430 | 618/850 | 140 | 868 | 1012 | 4 | 410 | 470 |

| 900 | 1090 | 85 | 5 | 618 | 1532 | 618/900 | 160 | 920 | 1070 | 4 | 350 | 410 |

| 950 | 1150 | 90 | 5 | 637 | 1730 | 618/950 | 190 | 968 | 1132 | 4 | 290 | 350 |

| Dimensions | Basic Load Rating | Part number | Weight | Installation Size | Limiting Speed | |||||||

| mm | kN | kg | mm | r/min | ||||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | ||

| 100 | 140 | 20 | 1.1 | 45 | 41.9 | 61920 | 0.96 | 106.5 | 133.5 | 1 | 4500 | 5300 |

| 110 | 150 | 20 | 1.1 | 47.9 | 47.8 | 61922 | 1.04 | 116.5 | 43.5 | 1 | 4100 | 4900 |

| 120 | 165 | 22 | 1.1 | 57.2 | 56.9 | 61924 | 1.41 | 126.5 | 158.5 | 1 | 3800 | 4400 |

| 130 | 180 | 24 | 1.5 | 69.6 | 70 | 61926 | 1.86 | 138 | 172 | 1.5 | 3400 | 4100 |

| 140 | 190 | 24 | 1.5 | 71.3 | 74.8 | 61928 | 1.98 | 148 | 182 | 1.5 | 3200 | 3800 |

| 150 | 210 | 28 | 2 | 85 | 90.5 | 61930 | 2.59 | 159 | 201 | 2 | 2800 | 3400 |

| 160 | 220 | 28 | 2 | 87 | 96 | 61932 | 2.71 | 169 | 211 | 2 | 2600 | 3200 |

| 170 | 230 | 28 | 2 | 88.8 | 100 | 61934 | 2.85 | 179 | 221 | 2 | 2400 | 3000 |

| 180 | 250 | 33 | 2 | 119 | 133 | 61936 | 4.16 | 189 | 241 | 2 | 2200 | 2800 |

| 190 | 260 | 33 | 2 | 117 | 133 | 61938 | 5.18 | 199 | 251 | 2 | 2200 | 2800 |

| 200 | 280 | 38 | 2.1 | 149 | 168 | 61940 | 7.28 | 211 | 269 | 2 | 2000 | 2600 |

| 220 | 300 | 38 | 2.1 | 152 | 178 | 61944 | 7.88 | 231 | 289 | 2 | 1900 | 2400 |

| 240 | 320 | 38 | 2.1 | 154 | 190 | 61948 | 8.49 | 251 | 309 | 2 | 1800 | 2200 |

| 260 | 360 | 46 | 2.1 | 210 | 268 | 61952 | 14 | 271 | 349 | 2 | 1600 | 1900 |

| 280 | 380 | 46 | 2.1 | 209 | 272 | 61956 | 15.1 | 291 | 369 | 2 | 1500 | 1800 |

| Dimensions | Basic Load Rating | Part number | Weight | Installation Size | Limiting Speed | |||||||

| mm | kN | kg | mm | r/min | ||||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | ||

| 300 | 420 | 56 | 3 | 270 | 375 | 61960 | 24.5 | 313 | 407 | 2.5 | 1300 | 1600 |

| 320 | 440 | 56 | 3 | 275 | 392 | 61964 | 25.3 | 333 | 427 | 2.5 | 1200 | 1500 |

| 340 | 460 | 56 | 3 | 292 | 418 | 61968 | 26.6 | 353 | 447 | 2.5 | 1100 | 1400 |

| 360 | 480 | 56 | 3 | 280 | 425 | 61972 | 27.9 | 373 | 467 | 2.5 | 1100 | 1400 |

| 380 | 520 | 65 | 4 | 338 | 540 | 61976 | 40 | 425 | 475 | 3 | 1000 | 1300 |

| 400 | 540 | 65 | 4 | 335 | 540 | 61980 | 42 | 416 | 524 | 3 | 950 | 1200 |

| 420 | 560 | 65 | 4 | 340 | 570 | 61984 | 43.6 | 436 | 544 | 3 | 900 | 1100 |

| 440 | 600 | 74 | 4 | 395 | 680 | 61988 | 60.2 | 456 | 584 | 3 | 900 | 1100 |

| 460 | 620 | 74 | 4 | 405 | 720 | 61992 | 62.6 | 476 | 604 | 3 | 850 | 1000 |

| 480 | 650 | 78 | 5 | 450 | 815 | 61996 | 73.5 | 500 | 630 | 4 | 800 | 950 |

| 500 | 670 | 78 | 5 | 460 | 865 | 619/500 | 82 | 520 | 650 | 4 | 750 | 900 |

| 530 | 710 | 82 | 5 | 455 | 870 | 619/530 | 89.8 | 550 | 690 | 4 | 750 | 900 |

| 560 | 750 | 85 | 5 | 525 | 1040 | 619/560 | 105 | 580 | 730 | 4 | 670 | 800 |

| 600 | 800 | 90 | 5 | 550 | 1160 | 619/600 | 120 | 620 | 780 | 4 | 630 | 750 |

| Dimensions | Basic Load Rating | Part number | Weight | Installation Size | Limiting Speed | |||||||

| mm | kN | kg | mm | r/min | ||||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | ||

| 630 | 850 | 100 | 6 | 625 | 1350 | 619/630 | 163 | 654 | 826 | 5 | 600 | 700 |

| 670 | 900 | 103 | 6 | 675 | 1460 | 619/670 | 181 | 694 | 876 | 5 | 530 | 630 |

| 710 | 950 | 106 | 6 | 715 | 1640 | 619/710 | 220 | 734 | 926 | 5 | 500 | 600 |

| 750 | 1000 | 112 | 6 | 785 | 1840 | 619/750 | 245 | 774 | 976 | 5 | 480 | 560 |

| 800 | 1060 | 115 | 6 | 825 | 2050 | 619/800 | 275 | 824 | 1036 | 5 | 430 | 500 |

| 850 | 1120 | 118 | 6 | 832 | 2160 | 619/850 | 310 | 873 | 1090 | 5 | 380 | 440 |

| 900 | 1180 | 122 | 6 | 852 | 2280 | 619/900 | 350 | 923 | 1157 | 5 | 320 | 380 |

| 950 | 1250 | 132 | 6 | 1010 | 2800 | 619/950 | 390 | 978 | 1222 | 5 | 260 | 320 |

Note:

1.Rate and speed in the catalogue is changed with the change of contact angle,please consult CHG technical department.

2.Our company can also produce diameter series 7 bearings(Super thin- section),please consult CHG technical department.

YOU MAY LIKE

VIEW MOREMetric Thin Section Bearings

VIEW MOREMetric Thin Section Bearings VIEW MOREType A Thin Section Bearing

VIEW MOREType A Thin Section Bearing VIEW MOREPrecision Angular Contact Ball Bearing

VIEW MOREPrecision Angular Contact Ball Bearing VIEW MOREType C Thin Section Bearing

VIEW MOREType C Thin Section Bearing VIEW MOREThin Section Four Point Contact Ball Bearings

VIEW MOREThin Section Four Point Contact Ball Bearings VIEW MOREThin Section Angular Contact Bearings

VIEW MOREThin Section Angular Contact Bearings VIEW MOREThin Section Radial Contact Ball Bearings

VIEW MOREThin Section Radial Contact Ball Bearings VIEW MOREThin Section Deep Groove Ball Bearings

VIEW MOREThin Section Deep Groove Ball Bearings