Advantages of Inch Series 4-Row Tapered Roller Bearings

Inch series four row tapered roller bearings are specialized engineering components designed to handle heavy loads in demanding industrial applications. These bearings feature four rows of tapered rollers, enabling them to support both axial and radial loads from multiple directions simultaneously. With their inch-based measurements and robust construction, they have become essential in steel mills, rolling mills, continuous casting machines, and other heavy industrial equipment requiring exceptional load capacity and operational stability.

What Makes Inch Series Four Row Tapered Roller Bearings Different from Other Bearing Types?

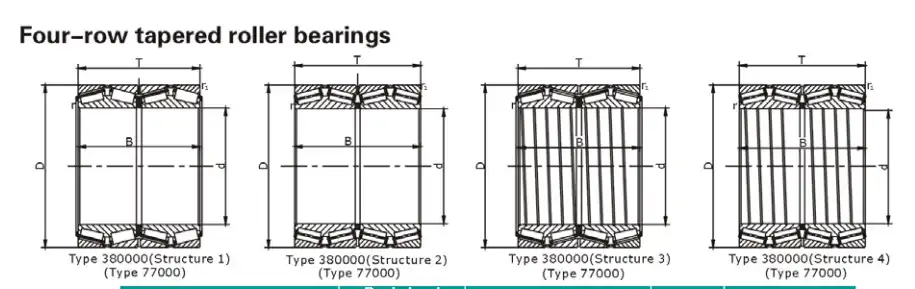

Distinctive Design Features of Inch Series Four Row Bearings

Inch series four row tapered roller bearings feature a unique arrangement of four rows of tapered rollers, typically configured in face-to-face or back-to-back patterns. This design enables them to handle complex load combinations that would overwhelm standard bearings. The tapered geometry creates optimal contact angles with the raceways, distributing forces evenly throughout the bearing assembly. Following imperial measurement standards, these bearings are particularly suitable for equipment designed with inch-based dimensions. They often include specialized cage designs that properly space and guide the rollers during operation, preventing skidding under severe conditions. The combination of four roller rows, precise tolerances, and robust materials gives inch series four row tapered roller bearings their exceptional performance in heavy-duty applications.

Load-Bearing Capabilities Compared to Other Bearing Types

Inch series four row tapered roller bearings significantly outperform most other bearing configurations in load capacity. They can simultaneously accommodate heavy radial and axial loads from multiple directions, with typical assemblies supporting radial loads exceeding 3,000 kN and thrust loads over 1,500 kN. This multi-directional capacity stems from the tapered roller geometry and strategic arrangement of the four rows, creating an interlocking system that efficiently distributes forces. Unlike spherical roller bearings, inch series four row tapered roller bearings provide superior rigidity and axial positioning precision. Compared to cylindrical roller bearings, which excel in pure radial loading but have limited axial capabilities, the four-row tapered design handles combined loading situations with remarkable efficiency. Their inch-based dimensions enhance compatibility with industrial equipment manufactured to imperial standards, making them indispensable where reliability under extreme conditions is essential.

Precision and Tolerance Advantages in Inch Measurement Systems

The inch measurement system provides specific advantages in certain manufacturing contexts. Precision in inch series four row tapered roller bearings is typically expressed in ten-thousandths of an inch (0.0001"), allowing for extremely fine control of clearances and fits. This precision is valuable in heavy industrial applications where thermal expansion must be carefully managed. The inch-based tolerance system has been historically preferred in North American and British engineering traditions, creating a substantial installed base of equipment designed around these specifications. Modern manufacturing techniques allow inch series four row tapered roller bearings to be produced with exceptional consistency, typically maintaining dimensional tolerances within ±0.001" for critical features. These precise tolerances ensure proper preload and clearance settings, directly impacting bearing performance and service life.

How Are Inch Series Four Row Tapered Roller Bearings Used in Industrial Applications?

Critical Applications in Steel and Rolling Mills

Steel and rolling mills represent one of the most demanding environments for bearings. In continuous casting machines, inch series four row tapered roller bearings support roller tables that guide hot steel slabs through cooling processes, enduring extreme temperatures and constant heavy loading. In rolling mill stands, these bearings are installed in work rolls and backup rolls, withstanding massive compression forces and shock loads during the rolling process. A typical modern rolling mill might subject bearings to radial loads exceeding 2,500 kN and operating temperatures above 100°C. The inch-based dimensions match historical specifications of many North American and British-designed mills, ensuring proper fits without requiring expensive retrofitting. Their ability to maintain precise positioning despite heavy loads ensures consistent product quality, while their robust construction, often utilizing case-hardened steel, provides durability against contamination from scale and cooling water.

Performance Characteristics in Mining and Construction Equipment

Mining and construction equipment subjects bearings to extreme conditions, making inch series four row tapered roller bearings ideal solutions. In excavators and draglines, these bearings support slewing mechanisms and boom pivots, where their ability to handle combined loads while maintaining precise positioning is crucial. In tunnel boring machines, they support main bearings of cutting heads, handling enormous thrust loads under challenging conditions. Underground mining equipment utilizes these bearings in gearboxes and cutter head supports, where their compact design relative to load capacity helps maximize limited space. Heavy construction equipment employs inch series four row tapered roller bearings in transmissions, wheel hubs, and articulation joints, where they withstand both static loads and dynamic forces. Their ability to handle shock loads without premature failure makes them particularly valuable in applications where unexpected downtime carries substantial financial implications.

Maintenance and Reliability Factors for Long-Term Operation

Maintaining inch series four row tapered roller bearings requires specific considerations for long-term reliability. Proper lubrication is critical, typically requiring heavy-duty industrial greases or circulating oil systems depending on the application. Monitoring programs often include vibration analysis, temperature tracking, and oil analysis to detect early signs of degradation. Installation procedures demand precision and specialized knowledge, as incorrect mounting can dramatically reduce service life. Many applications require specific preload or clearance settings that must be carefully established during installation and periodically verified during operation. When properly maintained, inch series four row tapered roller bearings demonstrate impressive longevity even in severe conditions, potentially operating continuously for 3-5 years in well-maintained steel mill applications before requiring replacement. The modular design of many inch series four row tapered roller bearings facilitates scheduled maintenance, allowing for bearing reconditioning rather than complete replacement in some applications.

Why Do Engineers Choose Inch Series Four Row Tapered Roller Bearings for Heavy-Duty Applications?

Load Distribution Mechanics and Stress Management

The sophisticated load distribution mechanics of inch series four row tapered roller bearings make them preferred for applications involving extreme forces. The tapered geometry creates optimal contact angles with raceways, allowing forces to be transmitted effectively while minimizing stress concentrations. In a four-row configuration, this capability is multiplied, with each row handling a portion of the overall load. The internal geometry is precisely calculated to create optimal pressure distribution across roller-raceway contacts, preventing edge loading that can lead to premature failure. Advanced designs incorporate profile modifications to roller and raceway surfaces, creating slight crown or logarithmic profiles that help compensate for elastic deformations under load, further optimizing stress distribution.

Thermal Management and Lubrication Considerations

Effective thermal management is critical for inch series four row tapered roller bearings in heavy-duty applications. The four-row configuration generates more friction and heat than simpler arrangements, necessitating sophisticated cooling and lubrication strategies. Engineers typically address this through circulating oil systems that simultaneously lubricate and cool the bearing assembly. The tapered roller geometry creates unique lubrication challenges, as sliding at roller end faces generates significant heat that must be managed through proper lubricant selection and delivery. High-performance synthetic lubricants are often specified, offering enhanced temperature stability and load-carrying capacity. Some advanced designs incorporate special lubricant routing features within the bearing itself, ensuring oil reaches critical surfaces even under extreme operating conditions.

Cost-Benefit Analysis for Long-Term Industrial Applications

Despite higher initial costs, inch series four row tapered roller bearings often emerge as economically advantageous in heavy industrial applications. The comprehensive evaluation must consider not only purchase price but also installation costs, maintenance requirements, expected service life, and potential downtime costs. In continuous process industries like steel production, where interruptions can cost thousands of dollars per minute, their superior reliability delivers substantial economic benefits. While these specialty bearings may cost 2-3 times more than simpler alternatives, this premium is justified when considering total lifecycle cost. Their backward compatibility with existing equipment designed to imperial standards eliminates the need for expensive modifications when replacing bearings in legacy machinery.

Conclusion

Inch series four row tapered roller bearings represent a specialized engineering solution for the most demanding industrial applications. Their unique design combines four rows of tapered rollers with imperial measurements to provide exceptional load capacity, precision, and durability. These bearings excel in critical applications across steel production, mining, and heavy equipment sectors, where their ability to handle extreme combined loads while maintaining precise positioning ensures operational reliability and efficiency. Their sophisticated engineering addresses complex challenges in load distribution, thermal management, and longevity that would overwhelm conventional bearing designs.

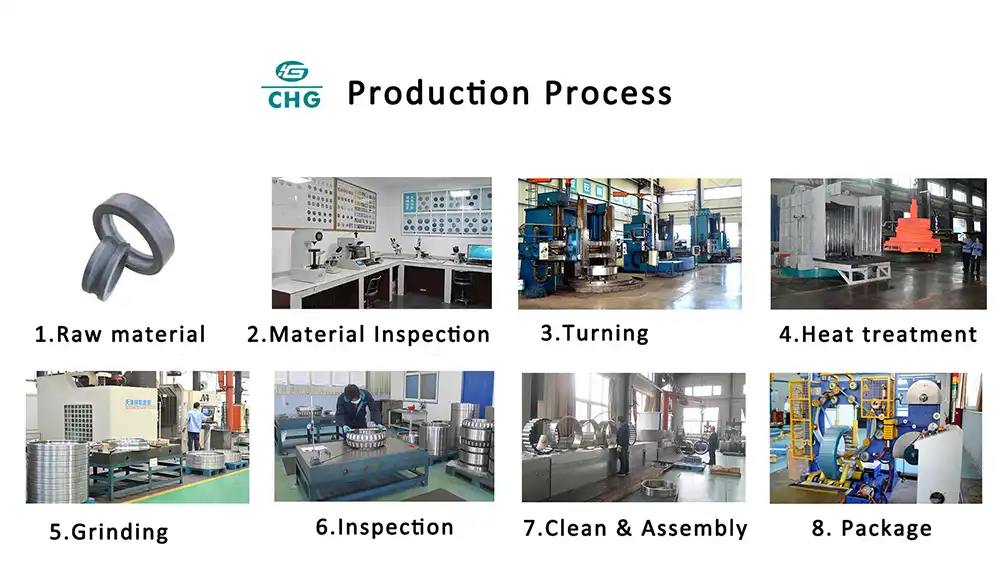

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A. & Kotzalas, M.N. (2022). Advanced Concepts of Bearing Technology: Rolling Bearing Analysis, Fifth Edition. CRC Press, Taylor & Francis Group.

2. Eschmann, P., Hasbargen, L., & Weigand, K. (2021). Ball and Roller Bearings: Theory, Design and Application, 4th Edition. John Wiley & Sons.

3. SKF Group. (2023). "Heavy-Duty Tapered Roller Bearings for Rolling Mill Applications." SKF Technical Handbook, Vol. 2, pp. 142-178.

4. Timken Company. (2024). "Engineering Manual for Inch Series Tapered Roller Bearings." Timken Technical Publications, 12th Edition.

5. Kragelsky, I.V., Dobychin, M.N., & Kombalov, V.S. (2023). Friction and Wear: Calculation Methods. Pergamon International Library.

6. NSK Ltd. (2023). "Four-Row Tapered Roller Bearings for Steel Industry Applications." NSK Technical Journal, Vol. 45, Issue 3, pp. 78-96.