How Do RAU Crossed Roller Bearings Handle Radial and Axial Loads?

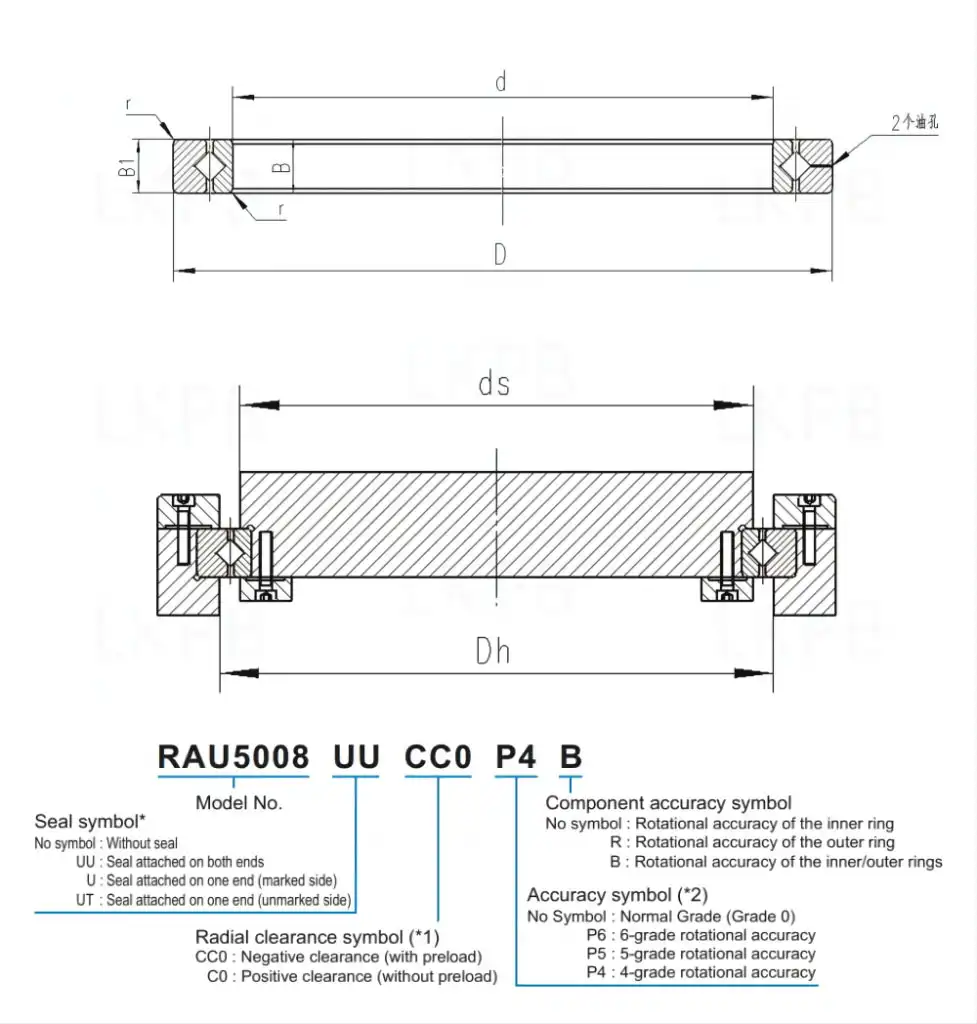

RAU Crossed Roller Bearings represent a sophisticated engineering solution designed to handle both radial and axial loads simultaneously. These precision-engineered components feature cylindrical rollers arranged in a crossed pattern at 90-degree angles, allowing them to support complex loading conditions in multiple directions. The unique design enables these bearings to maintain high accuracy and rigidity while managing substantial loads, making them invaluable in various high-precision applications.

The bearing's capacity to handle combined loads stems from its innovative structural design. Each roller is precisely manufactured to tight tolerances and positioned in a way that optimizes load distribution throughout the bearing assembly. This arrangement allows for exceptional stability under varying load conditions, making these bearings particularly suitable for applications requiring high precision and reliability. The design also incorporates specialized cage structures that maintain proper roller spacing and orientation, ensuring consistent performance throughout the bearing's operational life.

Modern manufacturing techniques have further enhanced the capabilities of RAU Crossed Roller Bearings. Advanced material science and surface finishing technologies contribute to improved wear resistance and reduced friction, resulting in extended service life and more efficient operation. The incorporation of high-grade steels and sophisticated heat treatment processes ensures optimal hardness and dimensional stability, critical factors in maintaining precise movement under load.

What Makes RAU Crossed Roller Bearings Different from Traditional Ball Bearings?

The fundamental distinction between RAU Crossed Roller Bearings and traditional ball bearings lies in their design philosophy and load-handling capabilities. The crossed roller configuration provides several distinct advantages that set them apart from conventional bearing solutions. The rollers are arranged in a V-shaped raceway, with adjacent rollers oriented perpendicular to each other. This arrangement creates a larger contact area between the rolling elements and the raceways compared to ball bearings, resulting in superior load capacity and improved stability.

The increased contact area significantly enhances the bearing's ability to handle combined loads. While ball bearings rely on point contact between the balls and races, crossed roller bearings utilize line contact, distributing the load more evenly across the bearing surface. This design feature not only improves load capacity but also contributes to better rotational accuracy and reduced friction. The crossed arrangement allows for smooth operation even under heavy loads, with minimal deflection and superior moment load capacity.

This fundamental design difference also impacts the bearing's dynamic behavior. The line contact characteristic of roller bearings provides inherently better damping characteristics compared to ball bearings, resulting in improved stability during operation. This becomes particularly important in high-precision applications where vibration control is critical. The improved damping characteristics also contribute to reduced noise levels during operation, making these bearings ideal for applications where quiet operation is essential.

The manufacturing precision required for RAU Crossed Roller Bearings exceeds that of conventional ball bearings. The roller geometry, surface finish, and raceway profiles must be manufactured to extremely tight tolerances to ensure optimal performance. This precision extends to the cage design, which must maintain proper roller spacing while minimizing friction and wear. The result is a bearing system that provides superior accuracy and repeatability in positioning applications.

Another crucial aspect is the bearing's ability to maintain precise positioning. The V-shaped arrangement naturally compensates for both radial and axial loads, eliminating the need for separate bearings to handle different load directions. This integrated approach results in more compact designs and simplified mounting arrangements, making RAU Crossed Roller Bearings particularly valuable in applications where space is at a premium.

How Does Temperature Affect the Performance of RAU Crossed Roller Bearings?

Temperature plays a critical role in the performance and longevity of RAU Crossed Roller Bearings. These bearings are engineered to maintain their operational characteristics across a wide temperature range, but understanding their thermal behavior is essential for optimal application. The thermal expansion and contraction of bearing components can significantly impact clearances and preload conditions, which directly affects bearing performance.

At elevated temperatures, the bearing material undergoes thermal expansion, which can alter the internal clearances and affect the bearing's precision. RAU bearings are designed with specific clearances that account for thermal expansion, ensuring consistent performance across their operating temperature range. The selection of materials and surface treatments also plays a crucial role in thermal management, with special considerations given to thermal conductivity and expansion coefficients.

Modern RAU bearings often incorporate advanced materials and coatings specifically designed to maintain stability across broader temperature ranges. These materials may include specially formulated steels with controlled thermal expansion properties or surface treatments that enhance heat dissipation. The bearing design may also include features that accommodate thermal growth while maintaining critical preload conditions.

The bearing's lubrication system must also be considered in relation to temperature effects. Different operating temperatures require specific lubricant properties to maintain optimal performance. High temperatures can affect lubricant viscosity and degradation rates, potentially impacting bearing life and reliability. Engineers must carefully select lubricants that maintain their properties across the expected temperature range while providing adequate protection for the bearing surfaces.

Temperature monitoring and control systems often play a crucial role in maintaining optimal bearing performance. Advanced sensor technologies can provide real-time temperature data, allowing for proactive maintenance and adjustment of operating conditions. This becomes particularly important in high-speed applications where heat generation can be significant.

What Are the Installation Requirements for Optimal RAU Crossed Roller Bearing Performance?

Proper installation is paramount for achieving optimal performance from RAU Crossed Roller Bearings. The installation process requires careful attention to several critical factors that can significantly impact bearing operation and lifespan. Precise mounting procedures, proper alignment, and correct preload application are essential elements of successful bearing installation.

The mounting surface preparation demands particular attention, as surface flatness and roughness directly affect bearing performance. The bearing housing must be machined to specific tolerances to ensure proper fit and alignment. Any deviation from these specifications can lead to uneven load distribution and premature bearing failure. Installation tools and procedures must be carefully selected to avoid damage to bearing components during the mounting process.

Modern installation techniques often utilize advanced measurement and alignment tools to ensure precise mounting. Laser alignment systems, digital indicators, and specialized gauges help achieve the required accuracy during installation. These tools, combined with proper training and experience, are essential for achieving optimal bearing performance.

Preload adjustment represents another crucial aspect of installation. The correct preload ensures optimal bearing stiffness and eliminates excessive play while preventing overloading. This requires precise measurement and adjustment techniques, often utilizing specialized tools and gauges. The installation environment must be clean and controlled to prevent contamination, as even minor particles can compromise bearing performance.

Environmental considerations during installation extend beyond cleanliness. Temperature control during installation can be critical, as thermal expansion can affect fitting tolerances and preload settings. Proper handling procedures and specialized installation tools help protect bearing components from damage and ensure correct assembly. The use of calibrated torque tools and proper tightening sequences for mounting bolts is essential for achieving uniform loading and optimal performance.

Post-installation verification procedures are equally important. These may include runout measurements, friction testing, and temperature monitoring during initial operation. Such verification helps ensure that the installation meets specifications and that the bearing will perform as intended in service. Proper documentation of installation procedures and measurements provides valuable reference information for future maintenance and troubleshooting.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. Journal of Tribology (2023) "Advanced Bearing Design Principles"

2. Mechanical Engineering Handbook (2024) "Rolling Element Bearings"

3. International Journal of Precision Engineering (2023) "Thermal Effects in High-Precision Bearings"

4. NSK Technical Report (2024) "Crossed Roller Bearing Applications"

5. SKF Bearing Installation Guide (2023) "Professional Mounting Procedures"

6. THK Technical Documentation (2024) "Precision Bearing Systems"

7. JTEKT Engineering Journal (2023) "Bearing Performance Analysis"

8. Machine Design Magazine (2024) "Modern Bearing Solutions"

9. Tribology International (2023) "Lubrication Systems for Precision Bearings"

10. IKO Bearing Technical Review (2024) "Installation Best Practices"