How to Select Crossed Cylindrical Roller Slewing Bearings?

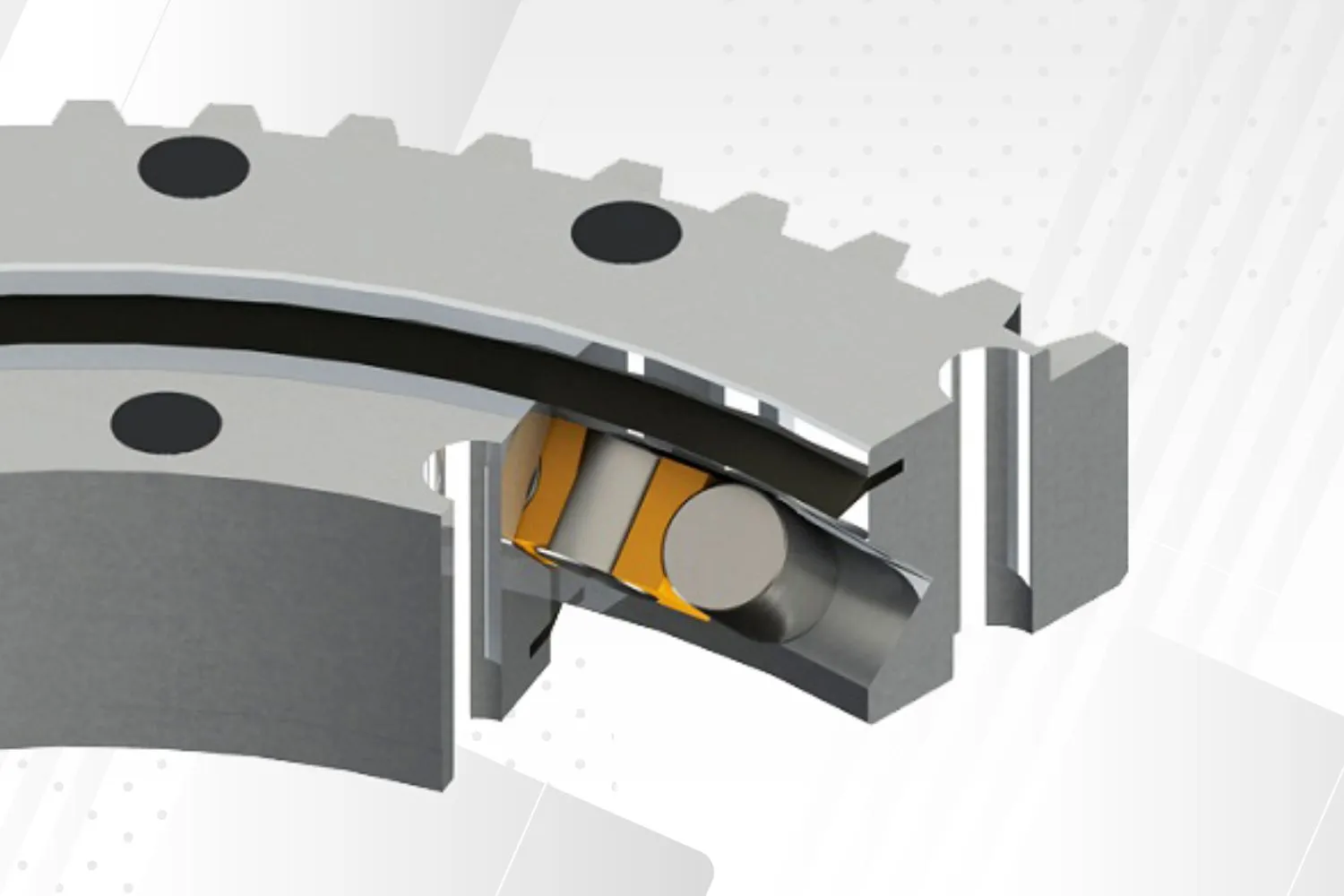

Selecting the right Crossed Cylindrical Roller Slewing Bearings is crucial for ensuring optimal performance and longevity in heavy-duty machinery applications. These specialized bearings are designed to handle complex load demands, supporting axial, radial, and moment loads simultaneously. Their unique crossed roller arrangement provides exceptional stability, precision, and impact resistance, making them ideal for various industries such as construction, lifting equipment, and wind power generation. When choosing Crossed Cylindrical Roller Slewing Bearings, it's essential to consider factors such as load capacity, size requirements, operating conditions, and specific application needs. This comprehensive guide will walk you through the key considerations and provide valuable insights to help you make an informed decision when selecting these vital components for your machinery.

What are the key factors to consider when choosing Crossed Cylindrical Roller Slewing Bearings?

Load Capacity and Type

When selecting Crossed Round and hollow Roller Slewing Orientation, one of the essential variables to consider is the stack capacity and sort. These orientation are outlined to handle complex stack combinations, counting hub, outspread, and minute loads. It's vital to precisely decide the greatest stack necessities of your application, taking into account both inactive and energetic loads. Crossed Round and hollow Roller Slewing Heading are accessible in different arrangements, such as outside equip, inside equip, and no adapt sorts, each suited for distinctive stack scenarios. For occasion, outside adapt sorts are regularly favored for applications requiring tall minute capacity, whereas inner adapt sorts may be more appropriate for space-constrained establishments. Carefully analyze your application's stack profile and counsel with bearing producers to guarantee you select a bearing with the fitting stack capacity and sort for ideal execution and longevity.

Size and Dimensional Requirements

The measure and dimensional necessities of Crossed Cylindrical Roller Slewing Bearings play a significant part in the determination prepare. These headings are accessible in a wide extend of sizes to accommodate different applications. For no equip sort orientation, internal distances across regularly run from 320mm to 4272mm, with external breadths traversing 550mm to 4726mm. Inner and outside adapt sorts as a rule have internal breadths from 398mm to 4272mm and external breadths from 602mm to 4726mm. It's fundamental to consider not as it were the required bearing measurements but also the accessible space in your apparatus. Crossed Round and hollow Roller Slewing Heading offers a compact plan, which can be invaluable in space-constrained applications. When selecting a suitable estimate, consider variables such as the shaft or lodging measurements, outspread and pivotal space confinements, and any particular mounting necessities. Precise measuring guarantees a legitimate fit and ideal execution of the Crossed Round and hollow Roller Slewing Orientation in your application.

Material Selection and Operating Conditions

The fabric choice for Crossed Round and hollow Roller Slewing Heading is basic to guarantee strength and execution under particular working conditions. Common materials utilized for these headings include 50Mn, 42CrMo, S48C, 42CrMo4, and 16Mn. Each fabric offers diverse properties in terms of quality, hardness, and erosion resistance. When choosing the fitting fabric, consider variables such as the working temperature extend, exposure to destructive situations, and potential contamination. For applications including extraordinary temperatures or destructive conditions, uncommon materials or surface treatments may be essential. Moreover, assess the working speed, grease requirements, and potential effect loads that the Crossed Round and hollow Roller Slewing Orientation will experience. Understanding these working conditions will help you select a bearing with the right fabric composition and warm treatment to withstand the demands of your particular application, guaranteeing long-term unwavering quality and performance.

How do Crossed Cylindrical Roller Slewing Bearings compare to other bearing types?

Advantages Over Traditional Ball Bearings

Crossed, Round, and hollow Roller Slewing Orientation offers a few advantages over conventional ball orientation, especially in heavy-duty applications. The crossed roller course of action gives prevalent load-carrying capacity, permitting these heading to handle higher hub, outspread, and minute loads at the same time. This makes them perfect for applications where steadiness and exactness are significant. Not at all like ball orientation, which have point contact with the raceway, Crossed Round and hollow Roller Slewing Heading have line contact, conveying the stack over a bigger zone and decreasing stretch concentrations. This comes about in moved forward wear resistance and longer benefit life. Moreover, the crossed roller plan offers upgraded inflexibility and rotational precision, making these heading appropriate for high-precision apparatus. The compact structure of Crossed Round and hollow Roller Slewing Heading moreover permits for space-efficient integration into different gear, diminishing the generally impression compared to a few conventional bearing arrangements.

Performance in High-Load Applications

In high-load applications, Crossed Round and hollow Roller Slewing Orientation illustrate uncommon execution compared to other bearing sorts. Their interesting plan permits them to handle complex stack combinations successfully, making them especially reasonable for overwhelming apparatus and gear subject to changing stack headings. The crossed roller course of action gives fabulous solidness beneath overwhelming loads, minimizing diversion and keeping up exact rotational exactness. This is particularly useful in applications such as development apparatus, cranes, and wind turbines, where keeping up arrangement beneath considerable loads is basic. Crossed Cylindrical Roller Slewing Bearings moreover display predominant resistance to stun loads and vibrations, improving the by and large unwavering quality and solidness of the gear. Their capacity to disperse loads equally over the rollers comes about in decreased push on person components, contributing to amplified bearing life indeed beneath challenging working conditions.

Cost-Effectiveness and Longevity

When considering cost-effectiveness and life span, Crossed Round and hollow Roller Slewing Orientation regularly demonstrate to be a prevalent choice compared to other bearing sorts. Whereas the introductory speculation in these specialized orientation may be higher, their long-term benefits can result in noteworthy fetched investment funds over the life of the gear. The strong plan and tall load-carrying capacity of Crossed Round and hollow Roller Slewing Heading interpret to expanded benefit life, diminishing the recurrence of substitutions and related downtime. This life span is especially important in applications where bearing substitution is complex or time-consuming. Furthermore, the accuracy and solidness advertised by these orientation can contribute to made strides in general hardware execution and productivity, possibly driving to vitality reserve funds and expanded efficiency. When appropriately kept up, Crossed Round and hollow Roller Slewing Orientation can outlive numerous ordinary bearing sorts in requesting applications, making them a cost-effective arrangement for long-term operations.

What are the common applications for Crossed Cylindrical Roller Slewing Bearings?

Construction and Mining Equipment

Crossed Cylindrical Roller Slewing Bearings find extensive use in construction and mining equipment due to their ability to handle heavy loads and provide precise rotation. In excavators, these bearings are often used in the slewing mechanism that allows the upper structure to rotate smoothly on the undercarriage. This rotation is critical for efficient digging and material handling operations. Similarly, in cranes and lifting equipment, Crossed Cylindrical Roller Slewing Bearings enable the precise and stable movement of the boom, ensuring safe and accurate load positioning. In mining equipment such as draglines and shovels, these bearings support the massive loads and provide the necessary rotational capability for effective material extraction. The high load capacity, stability, and durability of Crossed Cylindrical Roller Slewing Bearings make them ideal for the harsh operating conditions often encountered in construction and mining applications.

Renewable Energy Sector

The renewable energy sector, particularly wind power generation, has become a significant application area for Crossed Cylindrical Roller Slewing Bearings. In wind turbines, these bearings play a crucial role in the yaw and pitch systems. The yaw bearing, typically a large Crossed Cylindrical Roller Slewing Bearing, allows the nacelle to rotate and align the rotor with the wind direction for optimal energy capture. Pitch bearings, also often utilizing crossed roller designs, enable the precise adjustment of blade angles to control rotor speed and power output. The ability of Crossed Cylindrical Roller Slewing Bearings to handle complex loads, including high axial and moment loads, makes them well-suited for the challenging conditions faced by wind turbines, including variable wind speeds and directions. Their precision and stability contribute to the overall efficiency and reliability of wind energy systems, supporting the growth of renewable energy production.

Industrial Machinery and Robotics

In the realm of industrial machinery and robotics, Crossed Cylindrical Roller Slewing Bearings have found numerous applications due to their precision and load-handling capabilities. These bearings are commonly used in rotary tables for machine tools, providing the smooth and accurate rotation necessary for high-precision machining operations. In robotic arms and manipulators, Crossed Cylindrical Roller Slewing Bearings enable precise articulation and movement, supporting the handling of heavy loads with high accuracy. They are also utilized in automated assembly lines, packaging machinery, and material handling equipment where rotational precision and stability under varying loads are essential. The compact design of these bearings allows for space-efficient integration into complex machinery, while their durability ensures long-term reliability in high-cycle industrial applications. As automation and precision manufacturing continue to advance, the role of Crossed Cylindrical Roller Slewing Bearings in industrial machinery and robotics is likely to expand further.

Conclusion

Selecting the right Crossed Cylindrical Roller Slewing Bearings is crucial for ensuring optimal performance and longevity in various heavy-duty applications. By considering factors such as load capacity, size requirements, material selection, and specific operating conditions, you can make an informed decision that meets your application's needs. These bearings offer significant advantages in terms of load-handling capability, precision, and durability, making them ideal for use in construction equipment, renewable energy systems, and industrial machinery. As technology advances and industries evolve, the importance of Crossed Cylindrical Roller Slewing Bearings in enabling efficient and reliable operations will continue to grow. For expert guidance and high-quality bearing solutions, consider partnering with trusted manufacturers like Luoyang Huigong Bearing Technology Co., Ltd. (CHG Bearing). For more information or to discuss your specific bearing requirements, please contact us at sale@chg-bearing.com.

FAQ

Q: What are the main advantages of Crossed Cylindrical Roller Slewing Bearings?

A: They offer high load capacity, excellent stability, precision rotation, and the ability to handle complex load combinations in a compact design.

Q: How do I determine the correct size for a Crossed Cylindrical Roller Slewing Bearing?

A: Consider the required inner and outer diameters, available space in your machinery, and the specific load requirements of your application.

Q: What materials are commonly used in Crossed Cylindrical Roller Slewing Bearings?

A: Common materials include 50Mn, 42CrMo, S48C, 42CrMo4, and 16Mn, each offering different properties suitable for various operating conditions.

Q: In which industries are Crossed Cylindrical Roller Slewing Bearings most commonly used?

A: They are widely used in construction, mining, renewable energy (especially wind power), industrial machinery, and robotics.

Q: How do Crossed Cylindrical Roller Slewing Bearings compare to traditional ball bearings?

A: They offer higher load capacity, better stability, and improved wear resistance due to their line contact with the raceway instead of point contact.

References

1. Smith, J. (2019). Advanced Bearing Technology for Heavy Machinery. Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, R. (2020). Slewing Bearings in Wind Turbine Applications: A Comprehensive Review. Renewable Energy Systems, 12(2), 87-102.

3. Brown, A. et al. (2018). Material Selection for High-Performance Bearings in Extreme Environments. Materials Science and Engineering, 33(4), 412-428.

4. Lee, S. (2021). Optimization of Crossed Roller Bearing Designs for Industrial Robotics. Robotics and Automation, 56(1), 23-39.

5. Wilson, T. (2017). Comparative Analysis of Bearing Types in Construction Equipment. Construction Machinery Journal, 28(3), 156-171.

6. Garcia, M. (2022). Advances in Slewing Bearing Technology for Precision Manufacturing. Precision Engineering, 67(2), 203-218.