What Applications Use Tapered Roller Bearings?

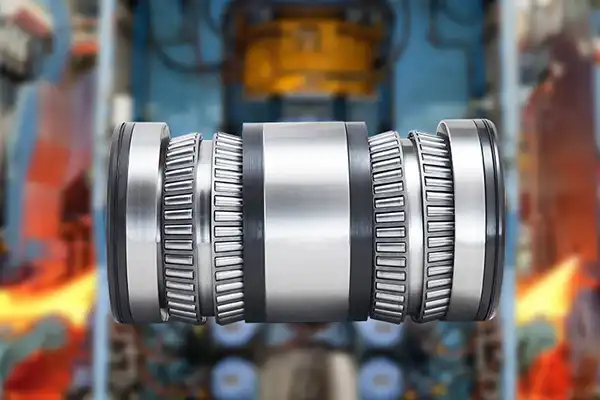

Tapered roller bearings are essential components in many mechanical systems, known for their ability to handle both radial and axial loads simultaneously. These bearings consist of tapered inner and outer raceways with tapered rollers between them, allowing for efficient load distribution and reduced friction. Due to their unique design and capabilities, tapered roller bearings find applications across various industries and machinery types. This blog post will explore the diverse applications of tapered roller bearings and address some common questions about their use.

How Do Tapered Roller Bearings Work in Automotive Applications?

Tapered roller bearings play a crucial role in the automotive industry, contributing to the smooth and efficient operation of various vehicle components. Their ability to handle combined loads makes them particularly suitable for automotive applications where both radial and axial forces are present. Let's delve into some specific areas where tapered roller bearings are extensively used in vehicles:

1. Wheel Hubs: One of the most common applications of tapered roller bearings in automobiles is in wheel hubs. These bearings support the weight of the vehicle (radial load) while also handling the side thrust (axial load) generated during cornering. The tapered design allows for precise wheel alignment and helps maintain proper tire contact with the road surface, enhancing vehicle stability and handling.

2. Transmission Systems: Tapered roller bearings are widely used in manual and automatic transmission systems. They support gears and shafts, helping to maintain proper alignment and reduce friction between moving parts. This application is critical for ensuring smooth gear shifts and efficient power transfer from the engine to the wheels.

3. Differentials: The differential system in vehicles, which allows wheels to rotate at different speeds during turns, relies heavily on tapered roller bearings. These bearings support the differential gears and pinions, enabling them to withstand the high loads and varying speeds encountered during vehicle operation.

4. Steering Systems: Tapered roller bearings are often used in steering columns and rack-and-pinion systems. They help reduce friction in the steering mechanism, providing drivers with smooth and responsive steering control.

5. Axle Assemblies: In both front and rear axle assemblies, tapered roller bearings support the axle shafts and help distribute the vehicle's weight evenly. This application is crucial for maintaining proper wheel alignment and ensuring smooth rotation of the axle.

The use of tapered roller bearings in these automotive applications offers several advantages:

- Improved load-carrying capacity: The tapered design allows for better distribution of combined radial and axial loads, which is essential in automotive systems.

- Enhanced durability: Tapered roller bearings can withstand the high stresses and vibrations encountered in vehicle operation, contributing to longer component life.

- Reduced friction: The rolling element design of these bearings minimizes friction, leading to improved fuel efficiency and reduced wear on vehicle components.

- Adjustable clearance: Many tapered roller bearing installations allow for precise adjustment of bearing clearance, ensuring optimal performance and longevity.

As automotive technology continues to advance, tapered roller bearings remain an integral part of vehicle design. Their reliability, efficiency, and load-handling capabilities make them indispensable in modern automobiles, contributing to improved performance, safety, and longevity of various vehicle systems.

What Industries Rely on Tapered Roller Bearings for Heavy Machinery?

Tapered roller bearings are not limited to automotive applications; they are also widely used in heavy machinery across various industries. Their robust design and ability to handle heavy loads make them ideal for demanding industrial environments. Let's explore some of the key industries that rely on tapered roller bearings for their heavy machinery:

1. Construction Industry:

The construction sector heavily depends on tapered roller bearings for the smooth operation of various types of heavy equipment. Some examples include:

- Excavators: Tapered roller bearings are used in the swing mechanism, boom, and bucket assemblies of excavators, allowing for precise and efficient movement.

- Bulldozers: These bearings support the tracks and drive systems, enabling bulldozers to operate smoothly under heavy loads.

- Cranes: Tower cranes and mobile cranes use tapered roller bearings in their slewing rings and hoisting mechanisms to ensure stable and controlled lifting operations.

2. Mining Industry:

Mining operations involve some of the most demanding applications for bearings due to extreme loads and harsh environmental conditions. Tapered roller bearings are used in:

- Conveyor systems: They support the rollers and drive shafts in conveyor belts, facilitating the efficient transport of mined materials.

- Crushing and grinding equipment: Tapered roller bearings are essential in rock crushers and grinding mills, where they must withstand high radial and axial loads.

- Mining vehicles: Large haul trucks and underground mining equipment rely on these bearings for their wheel hubs and drivetrain components.

3. Steel and Metal Processing:

The metal processing industry uses tapered roller bearings in various stages of production:

- Rolling mills: These bearings support the work rolls and backup rolls in hot and cold rolling mills, ensuring precise control of metal sheet thickness.

- Continuous casting machines: Tapered roller bearings are used in the segment rolls that guide the solidifying metal.

- Forging presses: Heavy-duty tapered roller bearings support the main shafts and eccentric gears in forging presses.

4. Paper and Pulp Industry:

Paper manufacturing equipment requires reliable bearings to operate efficiently:

- Paper machines: Tapered roller bearings are used in various sections of paper machines, including the wet end, press section, and calender stacks.

- Pulp refiners: These bearings support the high-speed rotors in pulp refiners, which are subjected to significant axial and radial loads.

5. Wind Energy:

The renewable energy sector, particularly wind power, relies on tapered roller bearings:

- Wind turbines: These bearings are used in the main shaft, gearbox, and yaw and pitch systems of wind turbines, helping to convert wind energy into electrical power efficiently.

The use of tapered roller bearings in these heavy machinery applications offers several benefits:

- High load capacity: Tapered roller bearings can handle the extreme radial and axial loads encountered in heavy industrial equipment.

- Shock resistance: Their design allows them to absorb and distribute shock loads effectively, enhancing equipment durability.

- Contamination resistance: Many tapered roller bearings used in heavy machinery are equipped with specialized seals to prevent contamination from harsh environmental factors.

- Extended service life: The robust construction of these bearings contributes to longer maintenance intervals and reduced downtime for industrial equipment.

As industries continue to push the boundaries of machinery performance and efficiency, tapered roller bearings remain a critical component in ensuring the reliability and productivity of heavy equipment across various sectors.

How Are Tapered Roller Bearings Maintained for Optimal Performance?

Proper maintenance of tapered roller bearings is crucial for ensuring their optimal performance and longevity, especially in demanding applications. Regular maintenance not only extends the life of the bearings but also contributes to the overall efficiency and reliability of the machinery in which they are installed. Let's explore the key aspects of tapered roller bearing maintenance and best practices for achieving optimal performance:

1. Lubrication Management:

Proper lubrication is perhaps the most critical aspect of tapered roller bearing maintenance:

- Selecting the right lubricant: Choose a lubricant that is appropriate for the specific application, considering factors such as operating temperature, speed, and load conditions.

- Maintaining proper lubricant levels: Ensure that bearings are neither under-lubricated nor over-lubricated, as both conditions can lead to premature failure.

- Regular relubrication: Establish a relubrication schedule based on the manufacturer's recommendations and operating conditions. In some cases, automatic lubrication systems may be employed for consistent and precise lubrication.

- Monitoring lubricant quality: Periodically check the condition of the lubricant for signs of contamination, degradation, or moisture ingress.

2. Cleanliness and Contamination Control:

Protecting tapered roller bearings from contaminants is essential for maintaining their performance:

- Proper sealing: Ensure that bearing housings and seals are in good condition to prevent the ingress of contaminants.

- Clean work environment: When performing maintenance or installation, work in a clean environment to minimize the risk of introducing contaminants.

- Filtration systems: In applications where bearings are part of a circulating oil system, implement and maintain effective filtration to remove particles and debris.

- Regular cleaning: During scheduled maintenance, clean the bearings and surrounding areas to remove any accumulated dirt or debris.

3. Alignment and Installation:

Correct alignment and installation are crucial for the proper functioning of tapered roller bearings:

- Precision mounting: Use appropriate tools and techniques to ensure precise mounting of bearings on shafts and in housings.

- Proper preload or endplay adjustment: Tapered roller bearings often require specific preload or endplay settings. Follow manufacturer guidelines to achieve the correct adjustment.

- Shaft and housing tolerances: Ensure that shaft and housing dimensions meet the required tolerances for optimal bearing performance.

- Regular alignment checks: Periodically verify the alignment of shafts and coupled equipment to prevent uneven loading on the bearings.

4. Condition Monitoring:

Implementing a condition monitoring program can help detect potential issues before they lead to bearing failure:

- Vibration analysis: Regular vibration measurements can identify developing bearing problems, allowing for timely intervention.

- Temperature monitoring: Unusual temperature increases can indicate lubrication issues or excessive loading.

- Oil analysis: For systems with circulating oil, periodic oil analysis can provide insights into bearing condition and lubricant health.

- Visual inspections: Regular visual checks can help identify visible signs of wear, damage, or lubricant leakage.

5. Handling and Storage:

Proper handling and storage of tapered roller bearings are essential for maintaining their integrity:

- Clean handling: Always handle bearings with clean hands or gloves to avoid introducing contaminants.

- Proper storage: Store bearings in a clean, dry environment, preferably in their original packaging, to protect them from moisture and contamination.

- Avoid static indentation: For bearings in storage or idle equipment, periodically rotate the inner ring to prevent static indentation of the raceways.

By following these maintenance practices, industries can significantly extend the life of tapered roller bearings, improve equipment reliability, and reduce overall maintenance costs. Regular attention to these aspects ensures that tapered roller bearings continue to perform optimally, supporting the efficient operation of machinery across various applications and industries.

In conclusion, tapered roller bearings are integral components in a wide range of applications, from automotive systems to heavy industrial machinery. Their unique design allows them to handle combined radial and axial loads efficiently, making them indispensable in many mechanical systems. By understanding the specific applications of tapered roller bearings and implementing proper maintenance practices, industries can maximize the performance and longevity of these critical components, ultimately contributing to improved efficiency, reliability, and productivity across various sectors.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. SKF Group. (2021). Tapered roller bearings.

2. Timken Company. (2022). Tapered Roller Bearing Catalog.

3. NSK Ltd. (2020). Roller Bearings.

4. Schaeffler Group. (2021). Tapered roller bearings.

5. NTN Corporation. (2022). Tapered Roller Bearings.

6. American Bearing Manufacturers Association. (2021). Bearing Briefs.

7. Machinery Lubrication. (2019). Tapered Roller Bearing Lubrication.

8. Construction Equipment. (2020). Bearing Maintenance for Heavy Equipment.

9. Wind Systems Magazine. (2021). The role of bearings in wind turbines.

10. Society of Tribologists and Lubrication Engineers. (2022). Bearing Lubrication Fundamentals.