What are Spherical Roller Bearings Normally Used For?

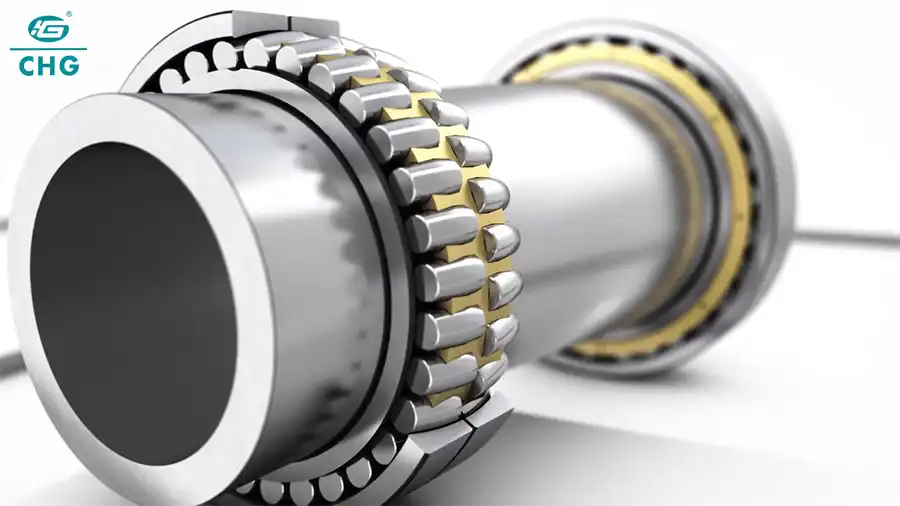

Spherical roller bearings are a type of rolling-element bearing designed to handle high radial and moderate axial loads in applications where misalignment, shaft deflections, or difficult mounting conditions are major factors. These versatile bearings consist of an inner ring with two raceways inclined at an angle to the bearing axis, an outer ring with a spherical raceway, and two rows of rollers. The unique design of spherical roller bearings allows them to accommodate angular misalignment and shaft deflections while maintaining optimal performance under heavy loads.

What are the Main Advantages of Spherical Roller Bearings?

Spherical roller bearings offer several significant advantages that make them an excellent choice for many industrial applications:

1. High Load Capacity: One of the primary benefits of spherical roller bearings is their ability to handle heavy radial and axial loads. The two rows of rollers distribute the load over a larger surface area, allowing these bearings to support much higher loads compared to other bearing types of similar size. This high load capacity makes them ideal for use in heavy machinery, such as mining equipment, steel mills, and paper processing plants.

2. Self-Aligning Capabilities: The spherical design of the outer ring raceway allows the bearing to automatically align itself, compensating for misalignment between the shaft and housing. This self-aligning feature is crucial in applications where shaft deflections or mounting errors are common, as it helps prevent premature bearing failure and extends the overall lifespan of the equipment.

3. Compact Design: Despite their high load capacity, spherical roller bearings have a relatively compact design. This allows for space-saving solutions in machinery design, enabling engineers to create more efficient and streamlined equipment. The compact nature of these bearings also contributes to reduced weight and material costs in many applications.

4. Tolerance to Shock Loads: Spherical roller bearings are well-suited to handle sudden, heavy loads or impact forces. The roller design and the ability to distribute loads across two rows of rollers help absorb and dissipate shock loads more effectively than many other bearing types. This makes them particularly useful in applications subject to frequent starts and stops or variable loading conditions.

5. Low Friction and Heat Generation: The rolling element design of spherical roller bearings results in lower friction compared to sliding bearings. This reduced friction leads to less heat generation during operation, which is crucial for maintaining optimal performance and extending the life of both the bearing and the machinery it supports. In high-speed applications, this can translate to significant energy savings and improved overall efficiency.

The combination of these advantages makes spherical roller bearings an excellent choice for many industrial applications, particularly those involving heavy loads, misalignment, or challenging operating conditions.

How Do You Properly Install Spherical Roller Bearings?

Proper installation of spherical roller bearings is crucial to ensure optimal performance and longevity. The installation process requires attention to detail and adherence to best practices. Here's a comprehensive guide to installing spherical roller bearings correctly:

1. Preparation:

Before beginning the installation, it's essential to prepare the work area and gather all necessary tools and equipment. Ensure that the work surface is clean and free from contaminants. Have the following items ready:

- Clean cloths

- Appropriate lubricant

- Mounting tools (such as an induction heater or hydraulic nut)

- Feeler gauges

- Micrometer or caliper

- Torque wrench

2. Inspect the Bearing and Surrounding Components:

Carefully examine the new bearing, shaft, and housing for any signs of damage or contamination. Even small imperfections can lead to premature bearing failure. Clean all components thoroughly using a lint-free cloth and appropriate cleaning solution.

3. Check Shaft and Housing Dimensions:

Measure the shaft and housing to ensure they meet the required tolerances for the bearing. Incorrect fits can lead to improper load distribution and reduced bearing life. Consult the manufacturer's specifications for the correct tolerances.

4. Lubrication:

Apply the appropriate lubricant to the bearing before installation. For grease-lubricated bearings, fill the bearing with the recommended grease type and quantity. For oil-lubricated systems, ensure that the oil passages are clear and that the system is ready to be filled after installation.

5. Mounting Method Selection:

Choose the appropriate mounting method based on the bearing size and application:

- Cold Mounting: Suitable for smaller bearings, this method involves pressing the bearing onto the shaft using mechanical tools.

- Heat Mounting: For larger bearings, heating the bearing (using an induction heater) expands it, allowing for easier installation on the shaft.

- Hydraulic Mounting: This method uses hydraulic pressure to expand the inner ring, facilitating installation on tapered shaft seats.

6. Installation Process:

a. For cold mounting:

- Align the bearing with the shaft and use a mounting sleeve to press it into place.

- Apply even pressure to the inner ring to avoid damaging the rolling elements.

b. For heat mounting:

- Heat the bearing evenly to the recommended temperature (typically 80-120°C above room temperature).

- Quickly slide the heated bearing onto the shaft and into position.

- Allow the bearing to cool naturally to room temperature.

c. For hydraulic mounting:

- Position the bearing on the tapered shaft seat.

- Use a hydraulic nut to inject oil between the bearing and shaft, creating a thin film that allows the bearing to slide into place.

- Once in position, release the oil pressure and allow the bearing to seat firmly.

By following these steps carefully, you can ensure that spherical roller bearings are installed correctly, setting the foundation for reliable and long-lasting operation. Proper installation is crucial for maximizing the bearing's performance and preventing premature failure, which can lead to costly downtime and repairs.

What Industries Commonly Use Spherical Roller Bearings?

Spherical roller bearings find applications across a wide range of industries due to their unique combination of high load capacity, self-aligning properties, and ability to handle both radial and axial loads. Here's an in-depth look at some of the key industries that commonly use spherical roller bearings:

1. Mining and Quarrying:

The mining industry heavily relies on spherical roller bearings for various applications. These bearings are used in equipment such as:

- Crushers: Spherical roller bearings support the heavy loads and shock loads experienced in rock crushers and grinding mills.

- Conveyors: Long conveyor systems benefit from the self-aligning properties of these bearings, accommodating slight misalignments due to uneven terrain.

- Screening equipment: The bearings help handle the vibrations and loads in vibrating screens used for material sorting.

- Excavators and draglines: Large earth-moving equipment utilizes these bearings in swing gears and other high-load applications.

2. Steel and Metal Production:

The steel industry uses spherical roller bearings in various stages of production:

- Rolling mills: These bearings support the heavy loads and high temperatures in hot and cold rolling processes.

- Continuous casting machines: The bearings help handle the loads and potential misalignments in the roller sections.

- Furnaces: Bearings in furnace equipment must withstand high temperatures and harsh conditions.

3. Pulp and Paper Manufacturing:

Paper mills use spherical roller bearings in several critical applications:

- Paper machines: These bearings support various rolls in the forming, pressing, and drying sections.

- Refiners and beaters: High-load capacity is crucial in pulp processing equipment.

- Winders and rewinders: The bearings help handle the varying loads as paper rolls change size.

4. Wind Energy:

Wind turbines rely on spherical roller bearings for critical components:

- Main shaft bearings: These bearings support the rotor and must handle both the weight and the varying wind loads.

- Gearbox bearings: High-speed and planetary gearboxes in wind turbines often use spherical roller bearings.

5. Marine and Offshore:

The maritime industry uses these bearings in various applications:

- Propulsion systems: Bearings support propeller shafts and other drive components.

- Deck machinery: Cranes, winches, and other deck equipment benefit from the bearings' high load capacity.

- Offshore drilling equipment: The bearings help handle the heavy loads and potential misalignments in drilling systems.

6. Construction and Earth-Moving Equipment:

Heavy construction machinery often incorporates spherical roller bearings:

- Excavators: The bearings are used in swing gears and boom systems.

- Bulldozers and loaders: Track rollers and drive components utilize these bearings.

- Cranes: Various points in mobile and tower cranes use spherical roller bearings to handle heavy loads.

7. Power Generation:

Power plants use spherical roller bearings in various equipment:

- Turbines: Both steam and gas turbines use these bearings in their support systems.

- Generators: Large generators benefit from the bearings' ability to handle both radial and axial loads.

- Pumps and fans: Auxiliary equipment in power plants often incorporates these bearings.

8. Oil and Gas:

The oil and gas industry uses spherical roller bearings in extraction and processing equipment:

- Drilling rigs: Top drives, drawworks, and mud pumps all utilize these bearings.

- Refineries: Pumps, compressors, and other processing equipment benefit from the bearings' capabilities.

The widespread use of spherical roller bearings across these industries demonstrates their versatility and reliability in handling challenging operating conditions. Their ability to accommodate misalignment, handle heavy loads, and operate in harsh environments makes them an indispensable component in many industrial applications. As technology advances, we can expect to see continued innovation in spherical roller bearing design, further expanding their capabilities and applications across various sectors.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF Group. (2021). Spherical roller bearings. SKF.com.

2. Timken Company. (2022). Spherical Roller Bearings. Timken.com.

3. NSK Ltd. (2020). Spherical Roller Bearings. NSK.com.

4. Schaeffler Group. (2021). Spherical roller bearings. Schaeffler.com.

5. NTN Corporation. (2019). Spherical Roller Bearings. NTN.com.

6. Rothe Erde GmbH. (2020). Spherical Roller Bearings in Mining Applications. Rothe-Erde.com.

7. ABB Group. (2021). Bearing selection for electric motors. ABB.com.

8. American Bearing Manufacturers Association. (2022). Bearing Types. ABMA.com.

9. Machinery Lubrication. (2018). How to Install Spherical Roller Bearings. MachineryLubrication.com.

10. Wind Systems Magazine. (2021). The role of bearings in wind turbine performance. WindSystemsMag.com.