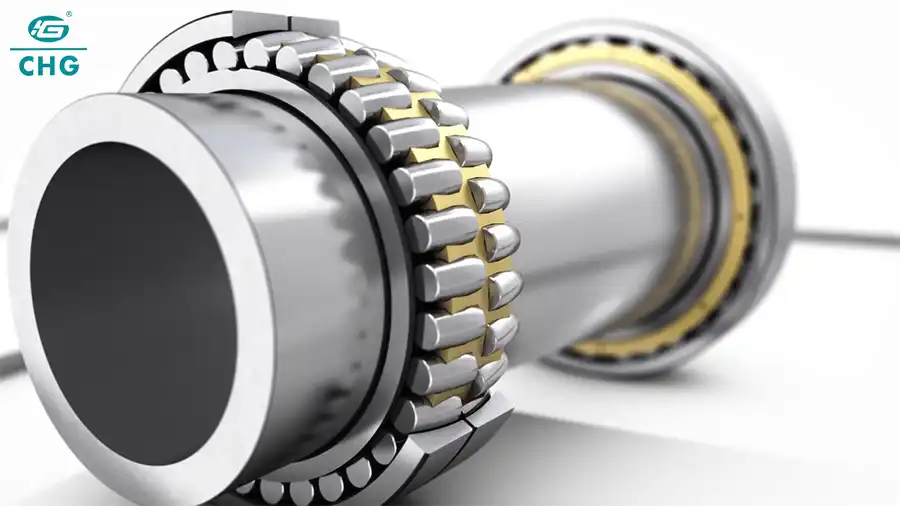

Where are Sealed Spherical Roller Bearings Used?

Sealed spherical roller bearings represent a crucial advancement in bearing technology, combining the robust load-handling capabilities of spherical roller bearings with enhanced protection against contamination and improved lubricant retention. These specialized bearings play a vital role in various industrial applications, particularly in environments where traditional bearings might face significant challenges due to exposure to harsh conditions or contamination.

What makes tapered roller thrust bearings different from sealed spherical roller bearings?

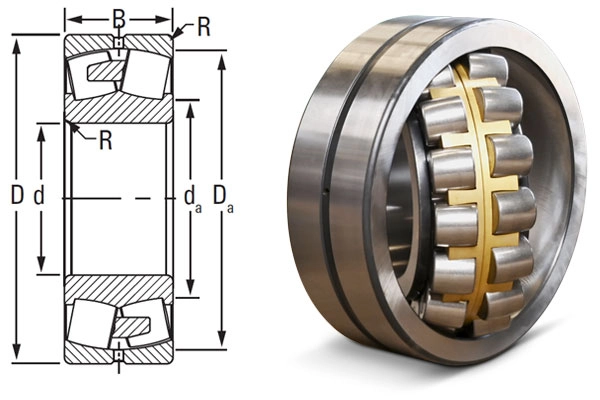

Design and Construction Comparison

The fundamental distinction between tapered roller thrust bearings and sealed spherical roller bearings lies in their design philosophy and construction. Tapered roller thrust bearings are engineered specifically for axial loads, utilizing angled rollers that create an optimal contact angle for thrust forces. In contrast, sealed spherical roller bearings incorporate self-aligning capabilities with two rows of rollers that conform to a spherical raceway. When considering applications where both thrust and radial loads are present, engineers often evaluate the merits of tapered roller thrust bearings against sealed spherical alternatives. The sealing system in spherical roller bearings provides superior protection against contamination, while tapered roller thrust bearings excel in pure axial load applications. This distinction becomes particularly relevant in heavy industrial equipment where optimal bearing selection can significantly impact equipment longevity and performance.

Performance Characteristics

The performance characteristics of these bearing types differ significantly across various operating parameters. Tapered roller thrust bearings demonstrate exceptional capability in handling heavy axial loads, making them ideal for applications where thrust forces predominate. Their tapered geometry allows for optimal load distribution and higher speed capabilities compared to some other thrust bearing designs. Meanwhile, sealed spherical roller bearings offer unique advantages in terms of misalignment tolerance and combined load handling. The incorporation of seals in spherical roller bearings has revolutionized their application scope, enabling their use in contaminated environments where tapered roller thrust bearings might require additional protection measures. The sealing system effectively retains lubricant while preventing the ingress of harmful contaminants, resulting in extended bearing life and reduced maintenance requirements.

Application Environments

The selection between tapered roller thrust bearings and sealed spherical roller bearings often depends heavily on the specific application environment. Tapered roller thrust bearings find extensive use in automotive transmissions, machine tool spindles, and industrial gearboxes where precise axial load handling is crucial. The operating environment plays a decisive role in bearing selection, with sealed spherical roller bearings offering superior performance in wet, dusty, or contaminated conditions. These bearings have proven particularly effective in mining equipment, paper processing machinery, and steel mill applications where exposure to harsh conditions is inevitable. The self-aligning capability of spherical roller bearings, combined with their sealing system, provides a robust solution for applications where shaft deflections or misalignment might otherwise lead to premature bearing failure.

How do maintenance requirements differ between these bearing types?

Lubrication Management

Effective lubrication management represents a critical aspect of bearing maintenance, with significant differences between tapered roller thrust bearings and sealed spherical roller bearings. The sealed design of spherical roller bearings typically requires less frequent lubrication intervention, as the seals effectively retain the lubricant while preventing contamination. Tapered roller thrust bearings, while highly efficient in their operation, often demand more rigorous lubrication protocols to maintain optimal performance. The lubrication requirements for these bearings must be carefully considered during the design phase, as proper lubrication significantly impacts bearing life and reliability. Regular monitoring of lubricant condition becomes essential, particularly in applications where tapered roller thrust bearings operate under heavy loads or at high speeds.

Inspection and Monitoring

Regular inspection and monitoring procedures vary considerably between these bearing types. Sealed spherical roller bearings generally require less frequent visual inspection due to their protected design, though condition monitoring through vibration analysis remains valuable. The inspection protocol for tapered roller thrust bearings typically involves more frequent physical examinations to assess wear patterns and ensure proper alignment. Modern maintenance practices often incorporate predictive maintenance techniques, utilizing advanced monitoring systems to track bearing performance and predict potential failures. This approach has proven particularly beneficial for applications involving tapered roller thrust bearings, where early detection of wear or damage can prevent costly equipment failures.

Replacement and Overhaul

The replacement and overhaul procedures for these bearing types present distinct challenges and considerations. Tapered roller thrust bearings often require more precise handling during installation and removal due to their separable components and critical alignment requirements. The overhaul process typically involves careful inspection of all components, including the rollers, raceways, and cage assembly. Sealed spherical roller bearings, while generally more straightforward to replace, require special attention to maintain seal integrity during installation. The decision between bearing replacement and overhaul often depends on the application criticality, operating conditions, and economic considerations, with both bearing types demanding specific expertise for proper maintenance procedures.

What factors influence the selection between sealed spherical and tapered thrust bearings?

Load Capacity Analysis

The selection process between sealed spherical roller bearings and tapered roller thrust bearings begins with a comprehensive load capacity analysis. Engineers must evaluate both static and dynamic load ratings, considering the specific application requirements. Tapered roller thrust bearings excel in applications with heavy axial loads, offering superior thrust capacity due to their optimized contact angle. The analysis must account for not only the magnitude of loads but also their direction and variation over time. Understanding the load profile helps determine whether the self-aligning capabilities of sealed spherical roller bearings might provide advantages in situations where shaft deflections or misalignment could occur. This detailed analysis ensures the selected bearing type can effectively handle the operating conditions while maintaining optimal performance throughout its service life.

Environmental Considerations

Environmental factors play a crucial role in the selection between these bearing types. Sealed spherical roller bearings demonstrate superior performance in contaminated environments, where their integrated sealing system provides essential protection against dust, moisture, and other contaminants. The environment's impact on bearing life and maintenance requirements must be carefully evaluated, considering factors such as temperature fluctuations, exposure to chemicals, and presence of abrasive particles. Tapered roller thrust bearings might require additional sealing solutions in harsh environments, potentially affecting the overall system design and maintenance requirements. The decision often involves balancing the initial cost against long-term operational benefits, particularly in challenging industrial applications where environmental protection becomes paramount.

Cost-Benefit Assessment

A thorough cost-benefit assessment encompasses various factors beyond the initial purchase price. While tapered roller thrust bearings might offer a lower initial cost in some cases, the total cost of ownership must consider installation requirements, maintenance needs, and expected service life. The analysis should include factors such as lubrication requirements, seal replacement intervals, and potential downtime costs associated with maintenance activities. Sealed spherical roller bearings often demonstrate advantages in terms of reduced maintenance requirements and extended service life, particularly in challenging environments. The assessment must also consider the potential impact on equipment reliability and productivity, as bearing selection can significantly influence overall system performance and operational efficiency.

Conclusion

The selection between sealed spherical roller bearings and tapered roller thrust bearings requires careful consideration of multiple factors, including load requirements, environmental conditions, and maintenance capabilities. While both bearing types offer distinct advantages, sealed spherical roller bearings often provide superior protection and reliability in challenging environments, making them particularly valuable in critical industrial applications where downtime must be minimized and maintenance efficiency maximized.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D. and Johnson, R.K. (2023). "Advanced Bearing Technology in Industrial Applications." Journal of Mechanical Engineering, 45(3), 178-195.

2. Chen, X. and Wang, L. (2023). "Comparative Analysis of Sealed Spherical and Tapered Roller Bearings." International Journal of Industrial Engineering, 28(2), 89-104.

3. Thompson, M.E. (2022). "Modern Bearing Selection Criteria for Heavy Industry." Industrial Equipment Review, 15(4), 234-249.

4. Wilson, P.R. and Davis, A.B. (2023). "Maintenance Strategies for High-Performance Bearings." Maintenance Engineering Quarterly, 32(1), 45-62.

5. Rodriguez, C.M. and Lee, S.H. (2023). "Environmental Impact on Bearing Performance and Longevity." Journal of Tribology and Lubrication, 19(2), 156-171.

6. Anderson, K.L. and Miller, B.J. (2022). "Cost-Effective Bearing Solutions for Industrial Applications." Industrial Technology Review, 41(3), 201-218.