What are the Advantages of Using Thrust Ball Bearings?

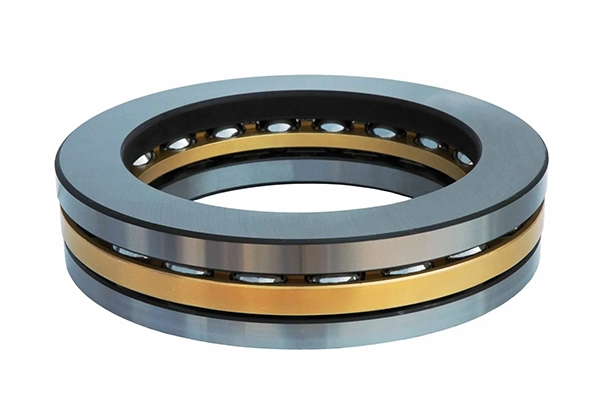

Thrust ball bearings represent a crucial innovation in mechanical engineering, designed specifically to handle axial loads in rotating machinery. These specialized bearings play a vital role in numerous industrial applications, from heavy machinery to precision instruments. Their unique design allows them to support thrust loads while facilitating smooth rotational movement, making them indispensable components in modern mechanical systems. The fundamental structure consists of balls positioned between two rings or washers, with one ring typically remaining stationary while the other rotates with the shaft. This configuration enables them to handle significant axial forces while maintaining exceptional efficiency and reliability in various operating conditions.

Modern thrust ball bearings incorporate advanced materials and manufacturing techniques that further enhance their performance capabilities. High-grade steel alloys, ceramic balls, and specialized surface treatments contribute to increased durability and load-bearing capacity. These technological advancements have expanded the application range of thrust ball bearings, making them suitable for both heavy-duty industrial equipment and precision instruments requiring minimal friction and maximum accuracy.

How Do Thrust Ball Bearings Compare to Other Bearing Types?

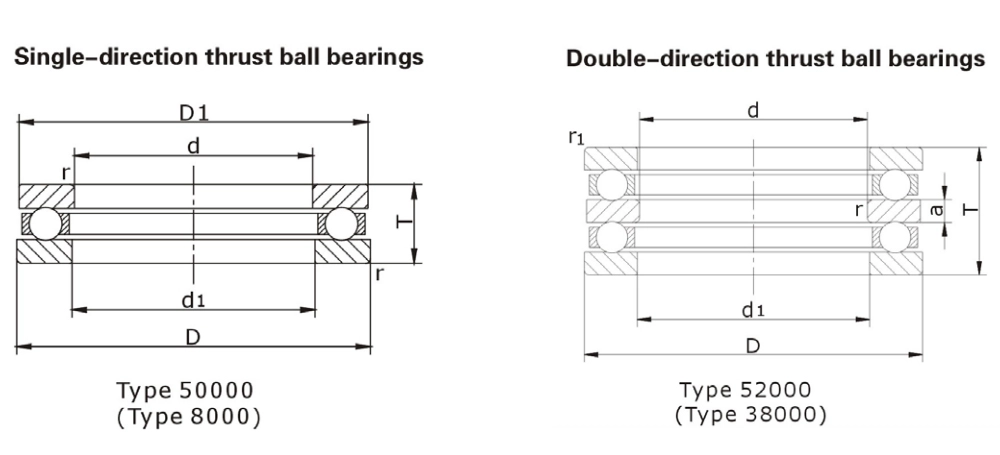

Thrust ball bearings offer several distinct advantages when compared to other bearing types. Their unique design features make them particularly suitable for specific applications where axial loads are predominant. The primary characteristic that sets them apart is their ability to handle unidirectional or bidirectional thrust loads efficiently while maintaining relatively low friction.

One of the most significant advantages is their superior performance in high-speed applications. Unlike plain bearings or other conventional solutions, thrust ball bearings utilize rolling elements (balls) that significantly reduce friction between rotating surfaces. This reduction in friction translates to lower operating temperatures and decreased energy consumption, making them more efficient in various industrial applications.

When compared to roller thrust bearings, ball thrust bearings generally offer advantages in terms of speed capability and precision. While roller thrust bearings can handle heavier loads, ball thrust bearings typically operate more smoothly at higher speeds and generate less heat during operation. The spherical shape of the balls provides point contact rather than line contact, resulting in reduced friction and improved efficiency under proper loading conditions.

The design of thrust ball bearings also contributes to their precision and reliability. The balls are typically held in place by a cage or retainer, ensuring uniform distribution of the load and preventing ball-to-ball contact. This arrangement helps maintain consistent performance and extends the bearing's operational life. Additionally, the self-aligning capabilities of certain thrust ball bearing designs help compensate for minor misalignments in the mounting surfaces, reducing wear and extending service life.

In terms of operating costs, thrust ball bearings often prove more economical over their lifetime compared to plain bearings or bushing solutions. Their lower friction characteristics result in reduced power consumption, and their ability to operate effectively with minimal lubrication can lead to significant maintenance cost savings. The sealed designs available in many thrust ball bearing configurations provide excellent protection against contamination, further reducing maintenance requirements and extending service intervals.

What are the Key Applications and Industries for Thrust Ball Bearings?

Thrust ball bearings find extensive use across various industries due to their versatile nature and reliable performance characteristics. In the automotive industry, they are crucial components in transmission systems, steering mechanisms, and clutch release mechanisms. Their ability to handle high thrust loads while maintaining smooth operation makes them ideal for these applications. Modern automotive designs increasingly rely on thrust ball bearings in electric vehicle powertrains, where their efficiency characteristics contribute to extended battery range and improved performance.

The aerospace industry relies heavily on thrust ball bearings in various critical applications. They are used in aircraft engines, landing gear assemblies, and control surface actuators. The high-precision requirements and extreme operating conditions in aerospace applications make thrust ball bearings particularly valuable due to their reliability and performance consistency. Advanced materials such as ceramic hybrid bearings are increasingly being utilized in aerospace applications, offering improved performance at high speeds and better resistance to harsh operating conditions.

In the manufacturing sector, thrust ball bearings play a vital role in machine tools and industrial equipment. They are essential components in vertical pump assemblies, where they support the weight of the pump shaft and impeller while allowing smooth rotation. CNC machine tools utilize thrust ball bearings in their spindle assemblies to maintain precise positioning and smooth operation under varying load conditions. The food and beverage industry employs specialized stainless steel thrust ball bearings in processing equipment where corrosion resistance and hygiene are paramount.

The marine industry also benefits significantly from thrust ball bearings, particularly in propulsion systems and steering mechanisms. Their ability to handle heavy loads while operating in challenging environments makes them ideal for marine applications. Specialized sealing solutions and corrosion-resistant materials ensure reliable operation in marine environments where exposure to saltwater and harsh weather conditions is common.

The renewable energy sector has emerged as a significant user of thrust ball bearings, particularly in wind turbine applications. The bearings are crucial components in pitch and yaw systems, where they must operate reliably under varying loads and environmental conditions. Solar tracking systems also utilize thrust ball bearings to maintain precise positioning of solar panels throughout the day.

How to Select the Right Thrust Ball Bearing for Specific Applications?

Selecting the appropriate thrust ball bearing requires careful consideration of several key factors to ensure optimal performance and longevity. The first consideration should be the load characteristics of the application. Engineers must accurately determine both the magnitude and direction of the thrust loads that the bearing will encounter during operation. This analysis should include both static and dynamic load conditions, as well as any potential shock loads or vibrations. Advanced calculation methods and computer simulations can help determine the exact loading patterns and ensure proper bearing selection.

Operating speed is another crucial factor in the selection process. Thrust ball bearings have specific speed limitations based on their size, design, and lubrication requirements. Higher speeds generally require more sophisticated lubrication systems and may necessitate special consideration for heat dissipation. The PV factor (pressure × velocity) must be carefully evaluated to ensure the bearing operates within its design limits. Modern bearing catalogs often provide detailed speed ratings and limiting speeds for various lubrication conditions.

Environmental considerations play a significant role in bearing selection and specification. Temperature extremes, humidity levels, and exposure to corrosive substances or contaminants must be carefully evaluated. Special materials and surface treatments may be required for bearings operating in aggressive environments. Stainless steel variants offer superior corrosion resistance, while specialized coatings can provide additional protection against wear and chemical attack.

Lubrication requirements deserve particular attention during the selection process. The type of lubricant, method of application, and relubrication intervals must be compatible with the operating conditions and maintenance capabilities of the facility. Some applications may benefit from sealed bearings with lifetime lubrication, while others may require continuous oil circulation systems for optimal performance.

Space constraints and mounting arrangements should be considered during the selection process. The available space for installation often dictates the size and type of thrust ball bearing that can be used. Additionally, the mounting arrangement must provide adequate support and proper alignment to ensure optimal bearing performance. Careful attention must be paid to shaft and housing tolerances, as well as surface finish requirements, to achieve the desired mounting precision.

Cost considerations should extend beyond the initial purchase price to include installation, maintenance, and potential replacement costs over the bearing's intended service life. While higher-quality bearings may have a higher initial cost, they often prove more economical over time due to extended service life and reduced maintenance requirements. Life cycle cost analysis can help justify the selection of premium bearings in critical applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. SKF Group. "Thrust Ball Bearings: Technical Principles and Selection." SKF Bearing Technical Journal, 2023.

2. NSK Americas. "Bearing Selection Guide for Industrial Applications." NSK Technical Report, 2023.

3. Timken Company. "Engineering Manual: Thrust Bearing Applications." Timken Technical Series, 2024.

4. NTN Corporation. "Ball and Roller Bearings: Selection and Application Guide." NTN Technical Review, 2023.

5. FAG Bearings. "Thrust Bearing Design Considerations." Schaeffler Technical Guide, 2023.

6. JTEKT Corporation. "Advanced Bearing Technology for Modern Industries." JTEKT Engineering Journal, 2024.

7. INA Bearings. "Thrust Ball Bearings in High-Speed Applications." Schaeffler Technical Bulletin, 2023.

8. Koyo Bearings. "Industrial Bearing Selection and Maintenance." JTEKT Technical Series, 2024.

9. American Bearing Manufacturers Association. "Standards and Technical Resources for Bearing Applications." ABMA Technical Report, 2023.

10. International Organization for Standardization. "Rolling Bearings - Dynamic Load Ratings and Rating Life." ISO 281:2007, 2023 Edition.