What are the Advantages of Crossed Cylindrical Roller Slewing Bearings?

Crossed Cylindrical Roller Slewing Bearings represent a sophisticated engineering solution that has revolutionized rotational motion in numerous industrial applications. These precision-engineered components are critical in managing complex mechanical interactions, providing unparalleled performance in scenarios requiring high load-bearing capacity, precise rotation, and exceptional durability. As modern industries continue to push the boundaries of mechanical design, these specialized bearings have emerged as a cornerstone technology that enables advanced mechanical systems to operate with remarkable efficiency and reliability.

How Do Crossed Cylindrical Roller Slewing Bearings Enhance Industrial Performance?

Crossed Cylindrical Roller Slewing Bearings stand at the forefront of mechanical engineering innovation, representing a pinnacle of design sophistication that addresses multiple critical challenges in industrial applications. The unique structural configuration of these bearings allows for an extraordinary distribution of load-bearing capabilities that far surpasses traditional bearing technologies.

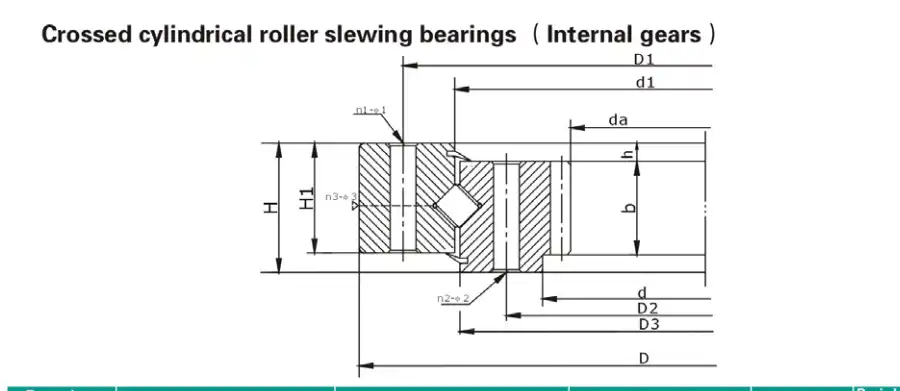

The fundamental advantage of these bearings lies in their intricate design, which incorporates cylindrical rollers arranged in a crossed pattern. This geometric arrangement creates a multi-directional load distribution mechanism that enables bearings to handle both radial and axial loads simultaneously with unprecedented efficiency. Unlike conventional bearings that struggle with complex loading conditions, crossed cylindrical roller bearings can manage enormous forces from multiple directions without compromising structural integrity.

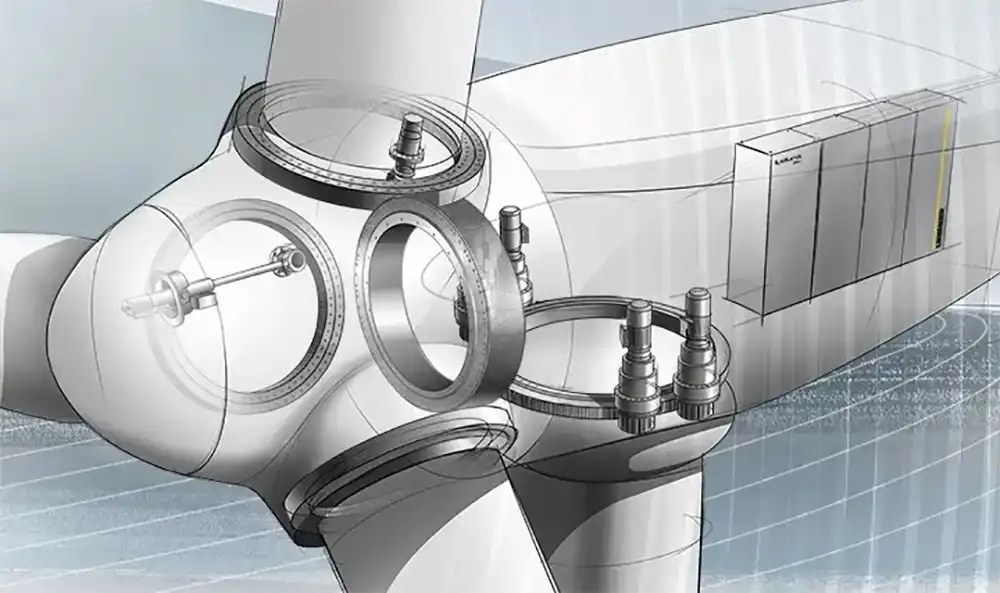

In practical industrial scenarios, this translates to remarkable performance characteristics. Heavy machinery in construction, maritime engineering, aerospace, and renewable energy sectors rely extensively on these bearings to manage extreme operational conditions. For instance, in large-scale wind turbines, these bearings must withstand constant environmental challenges—tremendous rotational forces, variable wind loads, and significant temperature fluctuations—while maintaining precise positioning and minimal friction.

The cross-roller configuration provides several critical advantages that set these bearings apart from alternative technologies. First, the intersecting roller arrangement ensures maximum contact area between rolling elements, which significantly reduces localized stress concentrations. This design principle means that loads are distributed more evenly, resulting in reduced wear and extended operational lifespan. Engineers have found that properly maintained crossed cylindrical roller bearings can operate effectively for decades, even under continuous heavy-load conditions.

Moreover, the precision engineering behind these bearings allows for minimal internal clearance, which directly correlates to improved positional accuracy. In robotic systems, astronomical telescope mounts, and sophisticated manufacturing equipment, this translates to micrometer-level positioning capabilities. The ability to maintain extremely tight tolerances makes these bearings indispensable in fields requiring exceptional mechanical precision.

Another remarkable aspect of crossed cylindrical roller bearings is their compact design relative to their load-bearing capacity. Traditional bearing systems often require substantial physical space and complex supporting structures. In contrast, these bearings achieve high performance in remarkably compact form factors. This space efficiency enables more streamlined mechanical designs across various engineering domains.

The material science behind these bearings further amplifies their performance. Typically manufactured using high-grade steel alloys with advanced heat treatment processes, they demonstrate exceptional resistance to fatigue, corrosion, and mechanical stress. Specialized surface treatments and lubrication technologies enhance their operational characteristics, allowing them to perform consistently in extreme environments ranging from arctic cold to tropical heat.

Why Are Crossed Cylindrical Roller Slewing Bearings Critical in Modern Engineering?

The significance of Crossed Cylindrical Roller Slewing Bearings extends far beyond their immediate mechanical function. They represent a sophisticated solution to complex engineering challenges that demand uncompromising performance, reliability, and precision.

In the renewable energy sector, these bearings play a transformative role in wind turbine technology. The massive nacelles of modern wind turbines must rotate smoothly to capture optimal wind conditions, and crossed cylindrical roller bearings enable this crucial functionality. They manage immense loads—often exceeding several hundred tons—while maintaining minimal friction and exceptional rotational accuracy.

The maritime industry presents another domain where these bearings demonstrate extraordinary capabilities. Large marine cranes, offshore drilling platforms, and sophisticated ship-based machinery rely on these bearings to manage complex rotational movements under challenging marine environments. The ability to withstand saltwater exposure, extreme loads, and constant motion makes them indispensable in maritime engineering applications.

Aerospace and defense technologies represent another critical area of application. Satellite communication systems, radar installations, and advanced tracking mechanisms depend on these bearings to provide precise, controlled rotation. The capacity to maintain accuracy in environments characterized by extreme temperature variations and minimal maintenance opportunities underscores their engineering excellence.

Robotics and advanced manufacturing systems increasingly incorporate these bearings to achieve unprecedented levels of precision. Robotic arms in automotive manufacturing, semiconductor production lines, and medical device fabrication require movement capabilities that traditional bearing technologies cannot provide. The crossed cylindrical roller design enables multi-axis rotation with minimal backlash and exceptional positional repeatability.

The economic implications of these bearings are equally significant. By reducing mechanical wear, minimizing maintenance requirements, and extending operational lifespans, they contribute to substantial long-term cost savings across industries. The initial investment in high-quality crossed cylindrical roller bearings is quickly offset by reduced downtime, lower replacement frequencies, and improved overall system efficiency.

Can Crossed Cylindrical Roller Slewing Bearings Transform Industrial Automation?

The potential of Crossed Cylindrical Roller Slewing Bearings to transform industrial automation is profound and multifaceted. As industries move towards more sophisticated, intelligent, and efficient mechanical systems, these bearings emerge as a critical technological enabler.

The potential of Crossed Cylindrical Roller Slewing Bearings to transform industrial automation is profound and multifaceted. As industries move towards more sophisticated, intelligent, and efficient mechanical systems, these bearings emerge as a critical technological enabler.

In the context of Industry 4.0, where interconnected, smart manufacturing systems are becoming the norm, these bearings represent more than mere mechanical components. They are integral to creating responsive, adaptive mechanical infrastructures that can rapidly adjust to changing operational requirements. The precision and reliability they offer make them fundamental to developing advanced robotic systems, automated production lines, and intelligent mechanical interfaces.

Emerging technologies like collaborative robotics particularly benefit from the characteristics of crossed cylindrical roller bearings. As robots work more closely with human operators, the need for smooth, predictable, and precise movements becomes paramount. These bearings enable robotic systems to execute complex multi-axis movements with a level of smoothness and accuracy that approaches human-like fluidity.

The integration of sensor technologies with these bearings opens up new frontiers in predictive maintenance and real-time performance monitoring. By embedding advanced sensors that can track rotational characteristics, load distributions, and potential wear indicators, industries can transition from reactive to predictive maintenance strategies. This represents a significant leap in operational efficiency and cost management.

As global industries continue to pursue sustainability and energy efficiency, the role of Crossed Cylindrical Roller Slewing Bearings becomes increasingly critical. Their ability to reduce friction, manage complex loads, and operate with minimal energy loss positions them as key components in the ongoing industrial transformation towards more sustainable technological solutions.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Hamrock, B. J., et al. "Fundamentals of Machine Elements." McGraw-Hill Education, 2017.

2. Dowson, D. "History of Tribology." Professional Engineering Publishing, 1998.

3. Kurokawa, Y. "Advanced Bearing Technologies." Springer, 2015.

4. SKF Group. "Slewing Ring Bearings: Technical Catalog." SKF Publications, 2020.

5. ISO 281:2007. "Rolling bearings — Dynamic load ratings and rating life."

6. Timken Company. "Bearing Design and Application Handbook." Timken Technical Publications, 2019.

7. SCHAEFFLER Group. "Industrial Handbook: Bearings and Lubrication." Schaeffler Technical Publications, 2018.

8. ASME Standard B106.1. "Design of Machine Elements."

9. NASA Technical Report: "Advanced Bearing Technologies in Aerospace Applications." NASA Technical Memorandum, 2016.

10. International Journal of Mechanical Engineering. "Crossed Cylindrical Roller Bearings: Performance Analysis and Design Considerations." Volume 45, 2019.