What is a Double Row Cylindrical Roller Bearing?

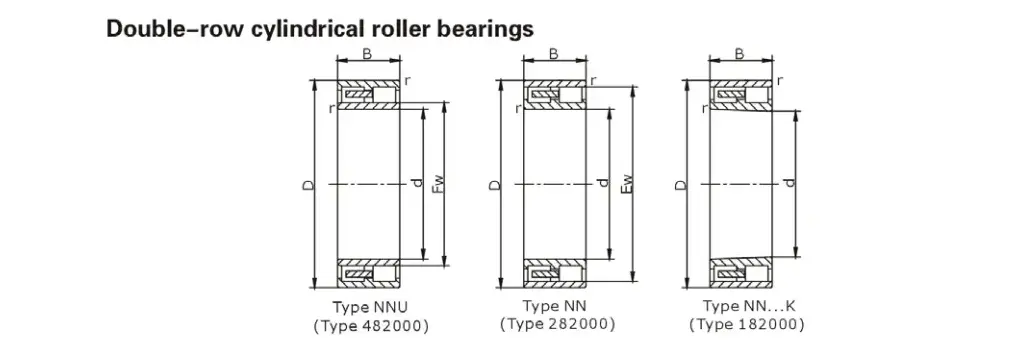

A double row cylindrical roller bearing is a type of rolling-element bearing that consists of two rows of cylindrical rollers arranged in parallel. These bearings are designed to handle heavy radial loads and moderate axial loads in both directions. They offer high radial load capacity, high stiffness, and excellent precision, making them ideal for various industrial applications where reliability and performance are crucial.

What are the advantages of double row cylindrical roller bearings?

Double row cylindrical roller bearings offer numerous advantages that make them a popular choice in various industries. These bearings are known for their exceptional performance characteristics and versatility. Here are some key advantages of double row cylindrical roller bearings:

- High radial load capacity: One of the primary advantages of double row cylindrical roller bearings is their ability to handle heavy radial loads. The two rows of rollers distribute the load evenly, allowing the bearing to support significantly higher loads compared to single-row bearings of similar size. This high load capacity makes them ideal for applications in heavy machinery, industrial equipment, and large-scale manufacturing processes.

- Excellent stiffness: Double row cylindrical roller bearings provide superior stiffness, which is crucial for maintaining precise shaft alignment and minimizing deflection under load. This characteristic is particularly important in machine tools, printing presses, and other applications where precision and stability are paramount.

- High-speed capability: These bearings are designed to operate efficiently at high speeds. The cylindrical rollers have a large contact area with the raceways, which helps distribute the load and reduce friction. This design allows for smooth operation even at elevated rotational speeds, making them suitable for high-speed machinery and equipment.

- Moderate axial load capacity: While primarily designed for radial loads, double row cylindrical roller bearings can also accommodate moderate axial loads in both directions. This feature adds to their versatility and makes them suitable for applications where both radial and axial forces are present.

- Low friction and heat generation: The cylindrical rollers in these bearings have a large contact area with the raceways, which helps distribute the load and reduce friction. This low friction design results in minimal heat generation during operation, contributing to increased efficiency and longer bearing life.

- Improved shaft alignment: The dual-row configuration of these bearings helps maintain proper shaft alignment, even under heavy loads or slight misalignment conditions. This feature is particularly beneficial in applications where maintaining precise alignment is critical for optimal performance.

- Enhanced stability: The two rows of rollers provide increased stability compared to single-row bearings. This stability is crucial in applications where vibration and shock loads are common, such as in heavy machinery and industrial equipment.

- Longer service life: Due to their robust design and load distribution capabilities, double row cylindrical roller bearings often have a longer service life compared to other bearing types. This extended lifespan translates to reduced maintenance requirements and lower overall operating costs for equipment owners.

- Compact design: Despite their high load capacity, double row cylindrical roller bearings have a relatively compact design. This feature allows for space-saving solutions in machinery design, where high performance is required within limited space constraints.

- Versatility: These bearings are available in various configurations and sizes, making them suitable for a wide range of applications across different industries. From small precision machinery to large industrial equipment, double row cylindrical roller bearings can be tailored to meet specific requirements.

The combination of these advantages makes double row cylindrical roller bearings an excellent choice for many demanding applications, providing reliable performance, longevity, and efficiency in various industrial settings.

How do you install and maintain double row cylindrical roller bearings?

Proper installation and maintenance of double row cylindrical roller bearings are crucial for ensuring optimal performance and longevity. Following the correct procedures can significantly extend the bearing's lifespan and prevent premature failure. Here's a comprehensive guide on how to install and maintain these bearings:

Installation Process:

- Preparation:

- Clean the shaft and housing thoroughly to remove any dirt, debris, or old lubricant.

- Inspect the shaft and housing for any damage or wear that could affect the bearing's performance.

- Ensure that all necessary tools and equipment are clean and in good condition.

- Bearing Selection:

- Verify that the selected bearing is the correct size and type for the application.

- Check the bearing for any visible defects or damage before installation.

- Mounting:

- For cold mounting, gently press the bearing onto the shaft using an appropriate mounting sleeve or press.

- For hot mounting, heat the bearing uniformly in an oil bath or induction heater to expand it slightly before installation.

- Never strike the bearing directly with a hammer or apply force to the rolling elements.

- Alignment:

- Ensure proper alignment of the bearing with the shaft and housing to prevent misalignment issues.

- Use appropriate alignment tools or gauges to verify correct positioning.

- Lubrication:

- Apply the recommended type and amount of lubricant before fully seating the bearing.

- Ensure even distribution of lubricant throughout the bearing.

- Final Assembly:

- Carefully install any seals, shields, or other components associated with the bearing assembly.

- Tighten all fasteners to the specified torque values.

Maintenance Procedures:

- Regular Inspection:

- Conduct visual inspections of the bearing and surrounding components for signs of wear, damage, or contamination.

- Listen for unusual noises or vibrations that could indicate bearing issues.

- Monitor operating temperatures to detect any abnormal heat generation.

- Lubrication Management:

- Follow the manufacturer's recommendations for lubrication intervals and quantities.

- Use high-quality lubricants suitable for the operating conditions and bearing type.

- Avoid over-lubrication, which can lead to increased heat generation and potential seal damage.

- Cleanliness:

- Keep the bearing and surrounding area clean to prevent contamination.

- Use appropriate seals and shields to protect the bearing from environmental contaminants.

- When performing maintenance, work in a clean environment to avoid introducing debris into the bearing.

- Alignment Checks:

- Periodically verify shaft and housing alignment to prevent uneven loading on the bearing.

- Address any misalignment issues promptly to prevent premature bearing failure.

- Vibration Analysis:

- Implement a vibration monitoring program to detect early signs of bearing wear or damage.

- Use vibration analysis tools to identify potential issues before they lead to catastrophic failure.

- Temperature Monitoring:

- Regularly check bearing operating temperatures using appropriate tools such as infrared thermometers.

- Investigate any significant temperature increases, as they may indicate lubrication problems or excessive loading.

- Documentation:

- Maintain detailed records of installation dates, maintenance activities, and any observed issues.

- Use this information to optimize maintenance schedules and predict potential failures.

- Training:

- Ensure that maintenance personnel are properly trained in bearing installation, maintenance, and troubleshooting techniques.

- Stay updated on the latest best practices and technologies related to bearing maintenance.

By following these installation and maintenance procedures, you can maximize the performance and lifespan of double row cylindrical roller bearings. Proper care and attention to detail during installation and ongoing maintenance will help prevent premature failures, reduce downtime, and optimize the overall efficiency of the equipment in which these bearings are used.

What are common applications for double row cylindrical roller bearings?

Double row cylindrical roller bearings find extensive use across various industries due to their unique combination of high radial load capacity, stiffness, and ability to handle moderate axial loads. These bearings are particularly well-suited for applications that require reliability, precision, and the ability to withstand harsh operating conditions. Here are some common applications where double row cylindrical roller bearings are frequently used:

- Heavy Machinery and Industrial Equipment:

- Construction equipment: Excavators, bulldozers, and cranes

- Mining machinery: Crushers, conveyors, and drilling equipment

- Steel mills: Rolling mills, continuous casting machines, and furnace equipment

- Paper mills: Rollers in paper-making machines

- Cement production equipment: Kilns and grinding mills

- Power Generation:

- Wind turbines: Main shaft bearings and gearbox bearings

- Hydroelectric generators: Turbine shaft bearings

- Steam turbines: Rotor support bearings

- Gas turbines: Shaft bearings in power generation units

- Automotive Industry:

- Transmissions: Gear shaft bearings

- Wheel hubs: Especially in heavy-duty trucks and commercial vehicles

- Engine components: Crankshaft bearings in large diesel engines

- Machine Tools:

- CNC machines: Spindle bearings

- Lathes and milling machines: Main spindle supports

- Grinding machines: Wheel spindle bearings

- Railway Industry:

- Locomotive axle bearings

- Traction motor bearings

- Gearbox bearings in rail vehicles

- Marine Applications:

- Propeller shaft bearings

- Engine crankshaft bearings in large marine diesel engines

- Winch and crane bearings on ships

- Aerospace:

- Aircraft engine bearings

- Landing gear components

- Helicopter rotor bearings

- Oil and Gas Industry:

- Pumps and compressors in refineries

- Drilling equipment bearings

- Offshore platform machinery

- Printing Industry:

- Roller bearings in printing presses

- Paper handling equipment

- Textile Machinery:

- Spinning and weaving machines

- Yarn processing equipment

In these applications, double row cylindrical roller bearings offer several advantages:

- High Load Capacity: The dual-row design allows for distribution of heavy radial loads, making them ideal for applications with significant weight or force.

- Precision and Stiffness: These bearings provide excellent shaft alignment and minimal deflection, crucial for machine tools and precision equipment.

- Speed Capability: They can operate efficiently at high speeds, making them suitable for fast-rotating machinery like turbines and machine tool spindles.

- Durability: Their robust design and ability to handle both radial and moderate axial loads contribute to extended service life in demanding environments.

- Compact Design: Despite their high load capacity, these bearings have a relatively compact form factor, allowing for space-efficient machine designs.

- Versatility: The ability to handle both radial and axial loads makes them suitable for a wide range of applications across different industries.

When selecting double row cylindrical roller bearings for specific applications, it's important to consider factors such as load requirements, speed, operating temperature, environmental conditions, and lubrication needs. Proper sizing and selection ensure optimal performance and longevity in the intended application.

As technology advances and industrial processes become more demanding, the applications for double row cylindrical roller bearings continue to expand. Their reliability, high load capacity, and versatility make them an essential component in many critical industrial and mechanical systems, contributing to improved efficiency and productivity across various sectors.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

- SKF Group. (2021). Cylindrical roller bearings.

- Timken Company. (2021). Cylindrical Roller Bearings.

- NSK Ltd. (2021). Cylindrical Roller Bearings.

- Schaeffler Group. (2021). Cylindrical roller bearings.

- NTN Corporation. (2021). Cylindrical Roller Bearings.

- American Bearing Manufacturers Association. (2021). Roller Bearings.

- Kaydon Bearings. (2021). Cylindrical Roller Bearings.

- Machine Design. (2019). What's the Difference Between Bearings?

- Power Transmission Engineering. (2018). Cylindrical Roller Bearings.

- Engineering360. (2021). Roller Bearings Information.