What is the Difference Between Single Row and Double Row Bearings?

Bearings are crucial components in various mechanical systems, designed to reduce friction between moving parts and support radial and axial loads. Among the many types of bearings available, single row and double row bearings are two common configurations that serve different purposes and offer distinct advantages. This blog post will explore the key differences between these bearing types, with a focus on single row cylindrical roller bearings, to help you understand which option might be best suited for your specific application.

What are the advantages of single row cylindrical roller bearings?

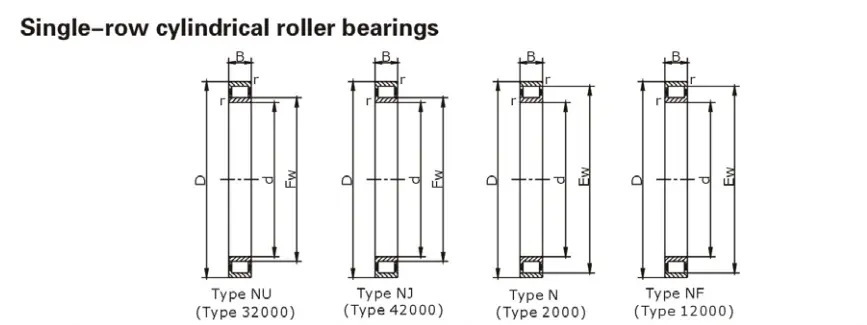

Single row cylindrical roller bearings are a popular choice in many industrial applications due to their unique design and performance characteristics. These bearings consist of a single row of cylindrical rollers held between an inner and outer ring. The rollers are guided by flanges on one of the rings, typically the outer ring, which allows for efficient radial load support and high-speed operation.

One of the primary advantages of single row cylindrical roller bearings is their exceptional radial load-carrying capacity. The line contact between the rollers and raceways distributes the load over a larger area compared to point contact bearings like ball bearings. This design feature allows single row cylindrical roller bearings to handle heavier radial loads while maintaining lower friction and heat generation.

Another significant advantage is their ability to accommodate misalignment and shaft deflection to a certain degree. While not as forgiving as spherical roller bearings, single row cylindrical roller bearings can still handle some minor shaft misalignment without significantly affecting their performance or lifespan. This characteristic makes them suitable for applications where perfect alignment is challenging to achieve or maintain.

Single row cylindrical roller bearings also excel in high-speed applications. Their design allows for efficient lubrication and heat dissipation, enabling them to operate at higher rotational speeds compared to some other bearing types. This makes them particularly valuable in machinery such as electric motors, gearboxes, and industrial pumps, where high-speed operation is often required.

Furthermore, these bearings offer excellent stiffness, which is crucial in applications requiring precise shaft positioning and minimal deflection under load. The rigid design of single row cylindrical roller bearings helps maintain accurate shaft alignment, contributing to improved overall system performance and reduced vibration.

Maintenance and installation of single row cylindrical roller bearings are generally straightforward. Many designs feature separable rings, allowing for easy mounting and dismounting. This characteristic is particularly beneficial in applications where frequent inspections or replacements are necessary, as it reduces downtime and simplifies maintenance procedures.

It's worth noting that while single row cylindrical roller bearings excel in radial load support, they typically have limited axial load-carrying capacity. In applications where significant axial loads are present, additional measures such as using thrust bearings or selecting bearings with appropriate flange configurations may be necessary.

How do double row bearings differ from single row bearings in terms of load capacity?

Double row bearings, as the name suggests, feature two rows of rolling elements (either balls or rollers) arranged within the inner and outer rings. This configuration offers several distinct advantages over single row bearings, particularly in terms of load capacity and stability.

The most significant difference between double row and single row bearings lies in their load-carrying capabilities. Double row bearings can generally handle much higher radial and axial loads compared to their single row counterparts. The presence of two rows of rolling elements effectively doubles the contact area between the rolling elements and the raceways, allowing for better load distribution and increased overall load capacity.

In terms of radial load capacity, double row bearings excel by distributing the load across two rows of rolling elements. This design feature allows them to handle heavier radial loads without compromising on performance or lifespan. The increased load capacity makes double row bearings particularly suitable for applications involving heavy machinery, such as industrial gearboxes, large electric motors, and heavy-duty conveyor systems.

Double row bearings also offer superior axial load-carrying capacity compared to most single row bearings. The two rows of rolling elements can effectively handle axial loads in both directions, providing enhanced stability and reducing the need for additional thrust bearings in many applications. This bi-directional axial load support is especially valuable in machinery subjected to varying or reversing axial loads, such as vertical pump shafts or machine tool spindles.

Another advantage of double row bearings in terms of load capacity is their ability to handle combined loads more effectively. In applications where both radial and axial loads are present simultaneously, double row bearings can often manage these complex loading conditions without the need for additional bearing arrangements. This capability can lead to simpler, more compact designs in many mechanical systems.

The increased stability provided by double row bearings is another factor that contributes to their enhanced load-carrying capacity. The wider effective width of double row bearings helps resist tilting moments and maintain proper alignment under heavy or uneven loading conditions. This improved stability can result in reduced vibration, quieter operation, and extended bearing life in demanding applications.

However, it's important to note that the increased load capacity of double row bearings comes with some trade-offs. Double row bearings are generally larger and heavier than their single row equivalents, which may be a consideration in applications where space and weight are critical factors. They also tend to generate more heat due to the increased number of rolling elements, potentially requiring more advanced lubrication and cooling systems in high-speed or high-load applications.

What factors should be considered when choosing between single row and double row bearings?

Selecting the appropriate bearing type for a specific application is crucial for ensuring optimal performance, longevity, and reliability of mechanical systems. When deciding between single row and double row bearings, several key factors should be carefully considered to make an informed choice.

Load characteristics are perhaps the most critical factor in bearing selection. Single row bearings, particularly single row cylindrical roller bearings, excel in handling high radial loads but often have limited axial load capacity. They are ideal for applications where radial loads dominate, such as in many types of electric motors and industrial fans. Double row bearings, on the other hand, offer superior combined load-carrying capacity, making them suitable for applications with significant radial and axial loads, like in heavy machinery or automotive wheel hubs.

Space constraints and weight considerations play a significant role in bearing selection. Single row bearings generally have a more compact design, making them suitable for applications where space is limited or weight is a concern. Double row bearings, while offering higher load capacity, are typically larger and heavier. In applications where minimizing size and weight is crucial, such as in aerospace or portable equipment, single row bearings might be preferred despite their lower load capacity.

Operating speed is another crucial factor. Single row cylindrical roller bearings are known for their excellent high-speed performance due to their low friction characteristics and efficient lubrication. They are often chosen for high-speed applications like turbines and high-speed electric motors. Double row bearings, while capable of handling higher loads, may have speed limitations due to increased heat generation from the additional row of rolling elements. For very high-speed applications, single row bearings might be more suitable unless the load requirements necessitate a double row configuration.

Misalignment tolerance is an important consideration in many real-world applications where perfect alignment is difficult to achieve or maintain. Single row cylindrical roller bearings have some ability to accommodate minor misalignment, but generally less than spherical roller bearings. Double row bearings, depending on their design, may offer better misalignment tolerance due to their wider effective width. In applications where significant misalignment is expected, specialized self-aligning bearings might be necessary.

Maintenance requirements and ease of installation should also be factored into the decision. Single row bearings, especially those with separable rings, often offer easier installation and maintenance. This can be advantageous in applications requiring frequent inspections or replacements. Double row bearings, while potentially more complex to install, may offer longer service intervals due to their higher load capacity and enhanced stability.

Cost considerations cannot be overlooked. Single row bearings are generally less expensive than their double row counterparts due to their simpler design and lower material requirements. In applications where load conditions permit, single row bearings might be preferred for their cost-effectiveness. However, it's important to consider the long-term costs, including potential downtime and replacement frequency, when making this decision.

Environmental factors such as temperature, contamination, and lubrication requirements also play a role in bearing selection. Single row cylindrical roller bearings often have good heat dissipation characteristics, making them suitable for high-temperature applications. Double row bearings may require more advanced sealing and lubrication systems due to their more complex internal geometry, especially in harsh environments.

Lastly, the specific application requirements and industry standards must be considered. Certain industries or applications may have specific regulations or best practices that favor one bearing type over another. For instance, in the automotive industry, double row angular contact ball bearings are commonly used in wheel hub assemblies due to their ability to handle combined radial and axial loads in a compact package.

In conclusion, the choice between single row and double row bearings depends on a careful analysis of the application's specific requirements. While single row bearings offer advantages in terms of speed, compactness, and cost-effectiveness, double row bearings excel in load capacity and stability. By thoroughly evaluating factors such as load characteristics, space constraints, operating speed, misalignment tolerance, maintenance requirements, cost, environmental conditions, and industry standards, engineers and designers can make informed decisions to ensure optimal bearing performance and longevity in their mechanical systems.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF Group. (2024). Cylindrical roller bearings.

2. Timken Company. (2024). Cylindrical Roller Bearings.

3. NSK Ltd. (2024). Roller Bearings.

4. Schaeffler Technologies AG & Co. KG. (2024). Cylindrical roller bearings.

5. NTN Corporation. (2024). Cylindrical Roller Bearings.

6. American Bearing Manufacturers Association. (2024). Bearing Types.

7. Bearing Briefs. (2023). Single Row vs. Double Row Bearings: Which is Right for Your Application?

8. Machine Design. (2022). Bearing Selection Guidelines.

9. Power Transmission Engineering. (2023). Choosing the Right Bearing for Your Application.

10. Engineering360. (2024). Roller Bearings Information.