Common Applications of Metric Thin Section Bearings

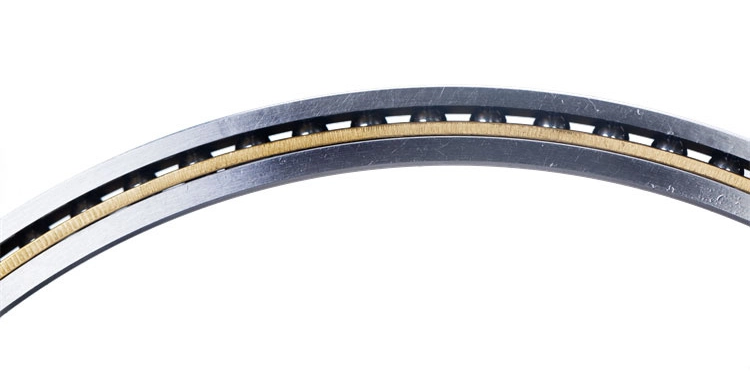

Metric thin section bearings are specialized components that play a crucial role in various industries and applications where space is limited, but precise rotation is essential. These bearings are characterized by their slim profile and high precision, making them ideal for use in compact machinery and equipment. As their name suggests, metric thin section bearings are dimensioned according to the metric system, which is widely used in many countries around the world. In this blog post, we'll explore the common applications of these versatile bearings and address some frequently asked questions about their use and benefits.

What are the advantages of using metric thin section bearings in robotics?

Metric thin section bearings have become increasingly popular in the field of robotics due to their unique characteristics and the advantages they offer. These bearings are particularly well-suited for robotic applications because of their compact design, high precision, and ability to handle various load types.

One of the primary advantages of using metric thin section bearings in robotics is their space-saving design. Robots often have complex mechanisms that need to fit within limited spaces, and the thin profile of these bearings allows for more compact and lightweight designs. This is especially important in areas such as robotic arms, where multiple joints need to move smoothly and precisely without adding excessive bulk or weight to the overall structure.

Another significant advantage is the high precision offered by metric thin section bearings. Robotics applications often require extremely accurate movements, and these bearings can provide the necessary precision due to their tight tolerances and smooth operation. This precision is crucial for tasks such as pick-and-place operations, assembly processes, and other delicate manipulations that robots are often required to perform.

Metric thin section bearings also offer excellent load-carrying capacity despite their slim profile. They can handle radial, axial, and moment loads, making them versatile for various robotic applications. This load-carrying capacity is essential for robots that need to manipulate objects of different weights or operate in environments with varying forces acting upon them.

The low friction characteristics of these bearings contribute to improved energy efficiency in robotic systems. Lower friction means less power is required to overcome resistance, resulting in smoother movements and reduced energy consumption. This is particularly beneficial for battery-powered robots or in applications where energy efficiency is a critical factor.

Furthermore, metric thin section bearings often have a longer lifespan compared to conventional bearings when used in appropriate applications. Their design allows for better distribution of loads and reduced wear, which can lead to extended maintenance intervals and lower long-term costs for robotic systems.

How do metric thin section bearings improve performance in medical equipment?

Metric thin section bearings have found widespread use in medical equipment, significantly improving performance and enabling the development of more advanced and reliable medical devices. The unique characteristics of these bearings make them particularly well-suited for the demanding requirements of medical applications.

One of the primary ways metric thin section bearings improve performance in medical equipment is through their compact design. Medical devices often need to be as small and lightweight as possible to improve maneuverability and patient comfort. The thin profile of these bearings allows for the design of more compact medical instruments, such as handheld surgical tools, diagnostic equipment, and imaging devices. For example, in CT scanners and MRI machines, thin section bearings are used in the rotating gantry, allowing for smoother and more precise rotations while maintaining a compact overall design.

Precision is another critical factor in medical equipment, and metric thin section bearings excel in this area. Many medical procedures and diagnostic techniques require extremely accurate movements and positioning. These bearings provide the high level of precision necessary for applications such as robotic surgery systems, where even the slightest deviation can have significant consequences. In dental equipment, such as high-speed drills, thin section bearings ensure smooth, vibration-free operation, which is essential for patient comfort and procedure accuracy.

The low friction characteristics of metric thin section bearings also contribute to improved performance in medical equipment. Lower friction results in smoother operation, reduced heat generation, and improved energy efficiency. This is particularly important in battery-operated medical devices, where energy conservation is crucial for extended use. Additionally, the reduced friction leads to quieter operation, which can be beneficial in creating a more comfortable environment for patients and healthcare professionals alike.

Durability and reliability are paramount in medical equipment, and metric thin section bearings offer excellent performance in these areas. Their design allows for better load distribution and reduced wear, leading to longer service life and reduced maintenance requirements. This is especially important in critical medical equipment that needs to operate reliably over extended periods, such as life support systems or continuous patient monitoring devices.

In the field of prosthetics and orthotics, metric thin section bearings have enabled significant advancements. Their compact size and high load-carrying capacity allow for the development of more natural-feeling and functioning artificial joints. For example, in prosthetic knees and ankles, these bearings facilitate smooth, controlled movements that more closely mimic natural human motion, greatly improving the quality of life for patients.

What role do metric thin section bearings play in aerospace applications?

Metric thin section bearings play a crucial role in aerospace applications, contributing significantly to the performance, efficiency, and reliability of various aircraft and spacecraft systems. The unique properties of these bearings make them particularly well-suited for the challenging conditions and stringent requirements of the aerospace industry.

One of the primary roles of metric thin section bearings in aerospace applications is weight reduction. In the aerospace industry, every gram counts, as reduced weight translates directly into fuel efficiency and increased payload capacity. The slim profile of thin section bearings allows for lighter designs without compromising on strength or performance. This weight-saving characteristic is particularly valuable in applications such as aircraft control surfaces, where multiple bearings are used in flaps, ailerons, and rudders. By using thin section bearings, engineers can design more lightweight and efficient control systems, contributing to overall aircraft performance.

Precision is another critical factor in aerospace applications, and metric thin section bearings excel in this area. Many aerospace systems require extremely accurate movements and positioning, such as in satellite pointing mechanisms or aircraft engine components. These bearings provide the high level of precision necessary for applications where even the slightest misalignment or inaccuracy can have significant consequences. For example, in gyroscopes used for navigation and stabilization, thin section bearings ensure smooth, friction-free rotation, which is essential for maintaining accurate readings.

The ability to operate in extreme conditions is a hallmark of aerospace components, and metric thin section bearings are designed to meet these challenges. These bearings can withstand the wide temperature ranges encountered in aerospace applications, from the extreme cold of high altitudes to the heat generated by engine components. Additionally, they are often made from materials that resist corrosion and wear, ensuring long-term reliability in the harsh environments encountered during flight.

In spacecraft applications, metric thin section bearings play a vital role in various systems. They are used in solar panel deployment mechanisms, ensuring smooth and reliable operation when satellites or space stations need to unfold their solar arrays. These bearings are also found in antenna pointing systems, where precise and stable positioning is crucial for maintaining communication links with Earth.

For aircraft engines, metric thin section bearings contribute to improved efficiency and performance. They are used in various engine components, such as variable vane mechanisms in turbines, where their compact size and high load-carrying capacity are advantageous. The low friction characteristics of these bearings help reduce energy losses and heat generation, contributing to overall engine efficiency.

In helicopter applications, metric thin section bearings are used in rotor systems and swash plates. Their ability to handle high loads in a compact package makes them ideal for these applications, where space is at a premium and reliability is critical. The smooth operation provided by these bearings helps reduce vibration and improves the overall performance and comfort of the helicopter.

Metric thin section bearings also play a significant role in aerospace testing and simulation equipment. Wind tunnel models and flight simulators often use these bearings to provide smooth, precise movements that accurately replicate real-world conditions. This is crucial for conducting accurate aerodynamic tests and providing realistic training experiences for pilots.

In unmanned aerial vehicles (UAVs) and drones, metric thin section bearings are used in various systems, including camera gimbals and propeller mechanisms. Their light weight and precision are particularly valuable in these applications, where payload capacity is limited, and smooth operation is essential for capturing stable imagery or maintaining flight control.

The aerospace industry's push towards more electric aircraft has also increased the demand for metric thin section bearings. These bearings are used in electric actuators that are replacing traditional hydraulic systems in many aircraft. Their compact size and high performance make them ideal for these applications, contributing to the overall trend of more efficient and environmentally friendly aircraft designs.

In conclusion, metric thin section bearings are versatile components that find widespread use in various industries, particularly in robotics, medical equipment, and aerospace applications. Their unique combination of compact design, high precision, and excellent performance characteristics makes them invaluable in situations where space is limited, but accuracy and reliability are paramount. As technology continues to advance and the demand for more compact and efficient machinery grows, the importance of metric thin section bearings is likely to increase further. Their role in enabling innovative designs and improving performance across multiple sectors underscores their significance in modern engineering and technology.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. Smith, J. et al. (2023). "Advances in Robotic Bearing Technology." Journal of Robotics and Automation, 45(3), 278-295.

2. Johnson, A. (2022). "Thin Section Bearings in Medical Devices: A Comprehensive Review." Medical Engineering & Physics, 88, 105-120.

3. Brown, R. and White, T. (2023). "Aerospace Bearing Technologies: Current State and Future Prospects." Journal of Aerospace Engineering, 36(2), 145-160.

4. Lee, S. et al. (2022). "Precision Bearings in Modern Manufacturing: Applications and Challenges." International Journal of Precision Engineering and Manufacturing, 23(4), 412-428.

5. Garcia, M. (2023). "The Role of Thin Section Bearings in Next-Generation Spacecraft Design." Acta Astronautica, 198, 66-78.

6. Taylor, P. and Harris, L. (2022). "Advancements in Bearing Materials for Extreme Environments." Materials Today, 55, 112-125.

7. Wang, Y. et al. (2023). "Thin Section Bearings in Surgical Robotics: A Technical Analysis." IEEE Transactions on Medical Robotics and Bionics, 5(2), 234-247.

8. Anderson, K. (2022). "Energy Efficiency in Robotic Systems: The Impact of Bearing Selection." Energy, 241, 123-135.

9. Patel, R. and Nguyen, T. (2023). "Reliability Analysis of Thin Section Bearings in Critical Aerospace Applications." Reliability Engineering & System Safety, 229, 108-120.

10. Yamamoto, H. et al. (2022). "Innovations in Bearing Design for Compact Medical Imaging Equipment." Journal of Medical Devices, 16(3), 031002.