What is a Type X Thin Section Bearing?

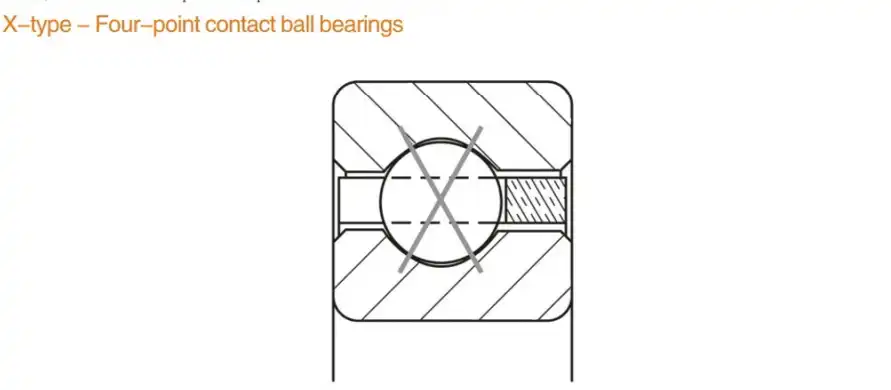

Type X thin section bearings are specialized precision components designed for applications where space is limited but high performance is crucial. These bearings are characterized by their exceptionally slim profile, which allows them to fit into tight spaces while still providing excellent rotational support. Type X bearings are part of the larger family of thin section bearings, but they have specific design features that set them apart. They typically have a cross-section that remains constant regardless of bore diameter, making them ideal for applications requiring a consistent bearing envelope across different sizes.

How do Type X thin section bearings differ from other bearing types?

Type X thin section bearings stand out from conventional bearings in several key aspects. The most notable difference is their remarkably thin cross-section, which can be up to 75% slimmer than standard bearings of comparable diameter. This slim profile is achieved through precision engineering and the use of high-quality materials, allowing Type X bearings to maintain impressive load-bearing capabilities despite their reduced size.

Unlike standard bearings, which often increase in cross-sectional thickness as the bore diameter grows, Type X bearings maintain a consistent cross-section across various sizes. This unique feature provides engineers with greater flexibility in design, as they can easily swap different sizes of Type X bearings without altering the overall dimensions of their assemblies.

The construction of Type X bearings also differs from standard bearings. They typically feature one-piece, lightweight races that are precision-ground to ensure optimal roundness and smooth operation. The balls or rollers within these bearings are often made of high-grade materials like chrome steel or ceramic, contributing to their durability and performance.

Another key difference lies in the contact angle between the balls and the races. Type X bearings often have a higher contact angle compared to standard bearings, which allows them to handle both radial and axial loads more effectively. This makes them particularly suitable for applications where complex loading conditions are present.

The manufacturing process for Type X bearings is generally more rigorous than that of standard bearings. Tighter tolerances are maintained throughout production, resulting in bearings with superior rotational accuracy and consistency. This precision is crucial in applications where even minute deviations can have significant impacts on overall system performance.

In terms of speed capabilities, Type X bearings often outperform their standard counterparts. Their reduced mass and optimized design allow for lower friction and heat generation, enabling higher rotational speeds. This makes them particularly valuable in high-speed applications where traditional bearings might struggle.

However, it's important to note that the specialized nature of Type X bearings can make them more expensive than standard options. Their use is typically justified in applications where the benefits of their slim profile and high performance outweigh the additional cost.

What are the primary applications for Type X thin section bearings?

Type X thin section bearings find extensive use across various industries due to their unique combination of compact size and high performance. One of the primary sectors benefiting from these bearings is the aerospace industry. In aircraft and spacecraft design, where every gram matters, Type X bearings allow for significant weight savings without compromising on reliability. They are commonly used in flight control systems, landing gear assemblies, and satellite deployment mechanisms.

The medical equipment industry is another major user of Type X bearings. In devices like CT scanners and MRI machines, these bearings enable the creation of more compact and precise rotating gantries. Their ability to handle both radial and axial loads makes them ideal for the complex movements required in these diagnostic tools. Surgical robots also benefit from the precision and compact nature of Type X bearings, allowing for more dexterous and accurate movements in minimally invasive procedures.

In the robotics field, Type X bearings have revolutionized the design of articulated arms and joints. Their slim profile allows engineers to create more compact and agile robotic systems, enhancing dexterity and range of motion. This is particularly valuable in industrial automation, where robots need to operate in confined spaces while maintaining high precision.

The semiconductor industry relies heavily on Type X bearings in various manufacturing equipment. Wafer handling systems, for instance, require extremely precise and smooth rotational movements, which these bearings can provide. Lithography machines, used in the production of microchips, also benefit from the high accuracy and stability offered by Type X bearings.

Optical and laser equipment manufacturers frequently incorporate Type X bearings into their designs. Telescope mounts, camera gimbals, and laser scanning systems all require precise, low-friction rotation, which these bearings excel at providing. The reduced weight of Type X bearings is particularly beneficial in portable optical equipment, where minimizing overall system weight is crucial.

In the automotive racing industry, where performance gains are measured in fractions of a second, Type X bearings offer valuable advantages. They are used in various components, from wheel hubs to transmission systems, where their low weight and high-speed capabilities contribute to overall vehicle performance.

Even in more traditional manufacturing settings, Type X bearings are finding increased use. CNC machines and 3D printers benefit from the precision and compact nature of these bearings, allowing for the creation of more accurate and efficient production equipment. The consistent cross-section of Type X bearings across different sizes also simplifies machine design and maintenance in these applications.

How do you select the right Type X thin section bearing for your application?

Selecting the appropriate Type X thin section bearing for a specific application requires careful consideration of several factors. The first and most crucial aspect to consider is the space available for the bearing. Type X bearings are designed for applications where space is at a premium, so accurate measurement of the available envelope is essential. This includes not just the radial space, but also the axial width available for the bearing.

Load requirements are another critical factor in bearing selection. Engineers need to calculate both the radial and axial loads that the bearing will be subjected to, including any dynamic loads or shock loads that may occur during operation. Type X bearings are available in different load ratings, and selecting one that can comfortably handle the expected loads is crucial for ensuring longevity and reliability.

The speed requirements of the application also play a significant role in bearing selection. While Type X bearings generally excel in high-speed applications, different models have varying speed ratings. It's important to choose a bearing that can handle the maximum expected rotational speed with an appropriate safety margin.

Environmental conditions are another key consideration. If the bearing will be exposed to extreme temperatures, corrosive substances, or contaminants, this needs to be factored into the selection process. Some Type X bearings are available with special seals or shields to protect against contamination, while others may be made from corrosion-resistant materials for harsh environments.

The precision requirements of the application should also guide the bearing selection. Type X bearings are available in different precision grades, with higher grades offering tighter tolerances and better rotational accuracy. For applications like optical equipment or precision machinery, selecting a higher precision grade may be necessary to meet performance requirements.

Lubrication is another factor to consider. Some Type X bearings come pre-lubricated and sealed, which can be advantageous in applications where regular maintenance is difficult. For other applications, the ability to re-lubricate the bearing may be important for long-term performance.

The mounting method for the bearing should also be taken into account. Type X bearings can be mounted in various ways, including press-fit, slip-fit, or with retaining rings. The chosen mounting method should be compatible with the overall design of the equipment and allow for proper support of the bearing.

Finally, cost considerations should not be overlooked. While Type X bearings offer superior performance in many applications, they are generally more expensive than standard bearings. It's important to weigh the performance benefits against the additional cost to ensure that the use of a Type X bearing is justified for the application.

In conclusion, Type X thin section bearings represent a significant advancement in bearing technology, offering a unique combination of compact size, high performance, and versatility. Their ability to provide excellent rotational support in space-constrained applications makes them invaluable across a wide range of industries. As technology continues to advance and the demand for miniaturization grows, the importance of Type X bearings is likely to increase further. By carefully considering the specific requirements of each application, engineers can leverage the advantages of these specialized bearings to create more efficient, precise, and compact machinery.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Kaydon Bearings. (2023). Thin Section Bearings.

2. SKF Group. (2024). Thin section bearings.

3. Machine Design. (2022). What are Thin Section Bearings?

4. Precision Bearings Ltd. (2023). Thin Section Bearings.

5. RBC Bearings. (2024). Thin Section Bearings.

6. NSK Americas. (2023). Thin-Section Bearings.

7. Aerospace Manufacturing and Design. (2022). Thin section bearings in aerospace applications.

8. AEC Online. (2023). The Benefits of Thin Section Bearings.

9. Bearing Tips. (2024). What are thin section bearings?

10. New Hampshire Ball Bearings. (2023). Thin Section Bearings.