What are the Advantages of a Single Row Tapered Roller Bearing?

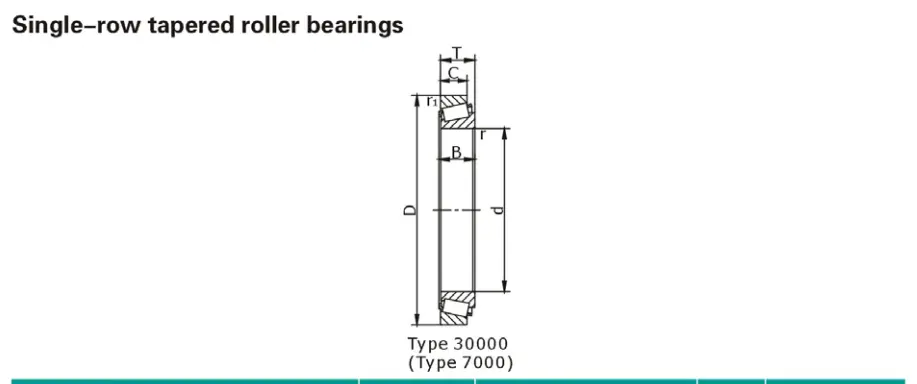

Single row tapered roller bearings represent one of the most versatile bearing types in mechanical engineering. These components feature tapered rollers positioned between inner and outer rings, creating a design that excels at handling combined loads. The tapered geometry allows these bearings to support substantial axial and radial forces simultaneously, making them invaluable across numerous industrial applications. This blog explores the advantages of single row tapered roller bearings, examining their performance characteristics and application versatility.

What Makes Single Row Tapered Roller Bearings Suitable for High Load Applications?

Superior Load Distribution Capabilities

Single row tapered roller bearings are engineered with a geometric design that provides exceptional load-carrying capacity. The tapered rollers are arranged at an angle that optimizes force distribution throughout the bearing assembly. This configuration allows them to handle higher loads compared to other bearing types of similar dimensions. The rollers make line contact with the raceways rather than point contact, increasing the contact area and distributing pressure more evenly. This design ensures that when heavy loads are applied, the stress is spread across a larger surface area, reducing failure risk and extending operational lifespan.

Enhanced Axial and Radial Load Management

One significant advantage of single row tapered roller bearings is their ability to simultaneously handle both axial and radial loads. The tapered geometry creates an optimal contact angle between rollers and raceways, enabling efficient management of forces from multiple directions. Unlike ball bearings that excel primarily at radial loads, or thrust bearings designed for axial forces, single row tapered roller bearings offer a comprehensive solution for combined loading scenarios. This versatility makes them valuable in applications where load directions may shift during operation or where space constraints prevent installing multiple bearing types.

Durability Under Shock and Vibration Conditions

Manufacturing environments frequently subject machinery to shock loads and persistent vibrations. Single row tapered roller bearings exhibit exceptional resilience against these challenging operating circumstances. Their robust construction, featuring precisely machined tapered rollers held in position by a cage, creates a stable configuration that withstands momentary overloads and irregular force patterns. The line contact between rollers and raceways distributes impact forces more effectively than point contact designs, preventing localized damage during shock events.

How Do Single Row Tapered Roller Bearings Improve Equipment Performance?

Precision Rotation and Reduced Friction

Single row tapered roller bearings enhance equipment performance through their ability to maintain precision rotation while minimizing friction. The tapered design creates optimal rolling contact that reduces sliding friction compared to cylindrical or spherical configurations. This geometric advantage results in lower operating temperatures and reduced energy consumption, improving efficiency across the entire mechanical system. The precise manufacturing tolerances ensure consistent running accuracy, which is critical in applications requiring exact positioning and smooth operation.

Extended Service Life and Maintenance Intervals

Equipment utilizing single row tapered roller bearings typically benefits from extended service life and longer maintenance intervals. These bearings are engineered with premium materials that resist wear, fatigue, and corrosion, enabling them to maintain performance characteristics over extended operational periods. The tapered design inherently manages contamination better than many alternative bearing types, as the angled roller arrangement can help direct debris away from critical contact surfaces. Their robust construction allows them to withstand higher operating temperatures while maintaining dimensional stability, which prevents premature wear.

Improved System Rigidity and Precision

Mechanical systems requiring high precision benefit greatly from the inherent rigidity provided by single row tapered roller bearings. Their geometrical configuration creates a stable platform that minimizes deflection under load, crucial for maintaining tight tolerances in precision machinery. When properly preloaded, these bearings effectively eliminate internal clearances, resulting in a system with exceptional stiffness that resists unwanted movement or vibration. This characteristic is particularly valuable in machine tools, where cutting accuracy directly impacts product quality.

Where Are Single Row Tapered Roller Bearings Most Commonly Used?

Automotive Applications and Wheel End Solutions

The automotive industry represents one of the largest markets for single row tapered roller bearings. Wheel hub assemblies typically incorporate pairs of these bearings to handle complex loading conditions experienced during driving. They simultaneously support the vehicle's weight while managing lateral forces during cornering and thrust loads during acceleration and braking. Beyond wheel ends, these bearings are found throughout automotive drivetrains, including transmissions and differentials, where their ability to handle combined loads while maintaining precise gear mesh is invaluable.

Industrial Machinery and Heavy Equipment

Industrial machinery and heavy equipment constitute another major application area for single row tapered roller bearings. In these demanding environments, machinery often operates continuously under substantial loads, making bearing reliability critical for operational efficiency. Mining equipment, construction machinery, and material handling systems incorporate these bearings at crucial rotation points where combined loads are present. Gearboxes frequently utilize them to support gear shafts while maintaining proper tooth alignment under varying load conditions.

Precision Engineering and Specialized Applications

Single row tapered roller bearings find application in specialized engineering fields where precision and reliability are paramount. Machine tool spindles benefit from the combination of load capacity and rigidity these bearings provide. Wind turbine gearboxes incorporate them at critical points where loads from massive blades create complex stress patterns. Railway rolling stock depends on these bearings in axle assemblies that must withstand enormous loads while ensuring safety and comfort.

Conclusion

Single row tapered roller bearings provide exceptional advantages through their unique design that effectively handles combined loads while offering precision, durability, and versatility across numerous applications. Their superior load distribution, extended service life, and contribution to system rigidity make them invaluable components in modern machinery. Whether in automotive, industrial, or specialized engineering fields, these bearings consistently deliver reliable performance under challenging conditions, reducing maintenance requirements and improving overall equipment efficiency.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A. and Kotzalas, M.N. (2023). "Advanced Concepts of Bearing Technology: Rolling Bearing Analysis." CRC Press, 5th Edition.

2. Eschmann, P., Hasbargen, L., and Weigand, K. (2022). "Ball and Roller Bearings: Theory, Design, and Application." John Wiley & Sons, 4th Edition.

3. SKF Group. (2024). "Tapered Roller Bearings: Engineering Principles and Applications." SKF Technical Publication.

4. Zaretsky, E.V. (2021). "Rolling Bearing Life Prediction, Theory, and Application." NASA/TP-2021-219573.

5. Timken Company. (2023). "Tapered Roller Bearing Design and Performance Analysis." Timken Engineering Journal, Vol. 7.

6. ISO 492:2022. "Rolling bearings — Radial bearings — Geometrical product specifications (GPS) and tolerance values." International Organization for Standardization.