Single Row Cylindrical Roller Bearing

Generally, a single-row cylindrical roller ring consists of four major components as follows:

inner ring, outer ring, rollers, and cage.

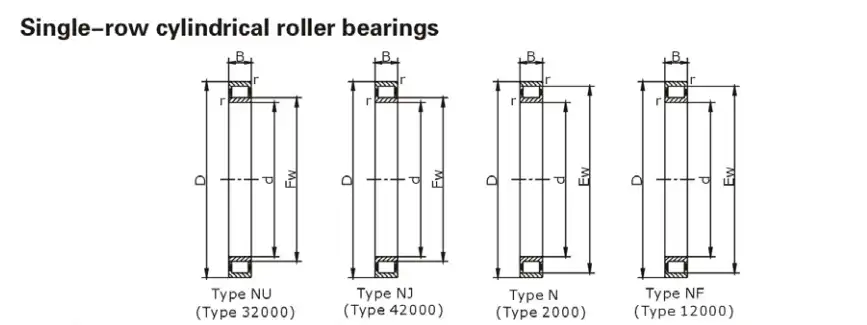

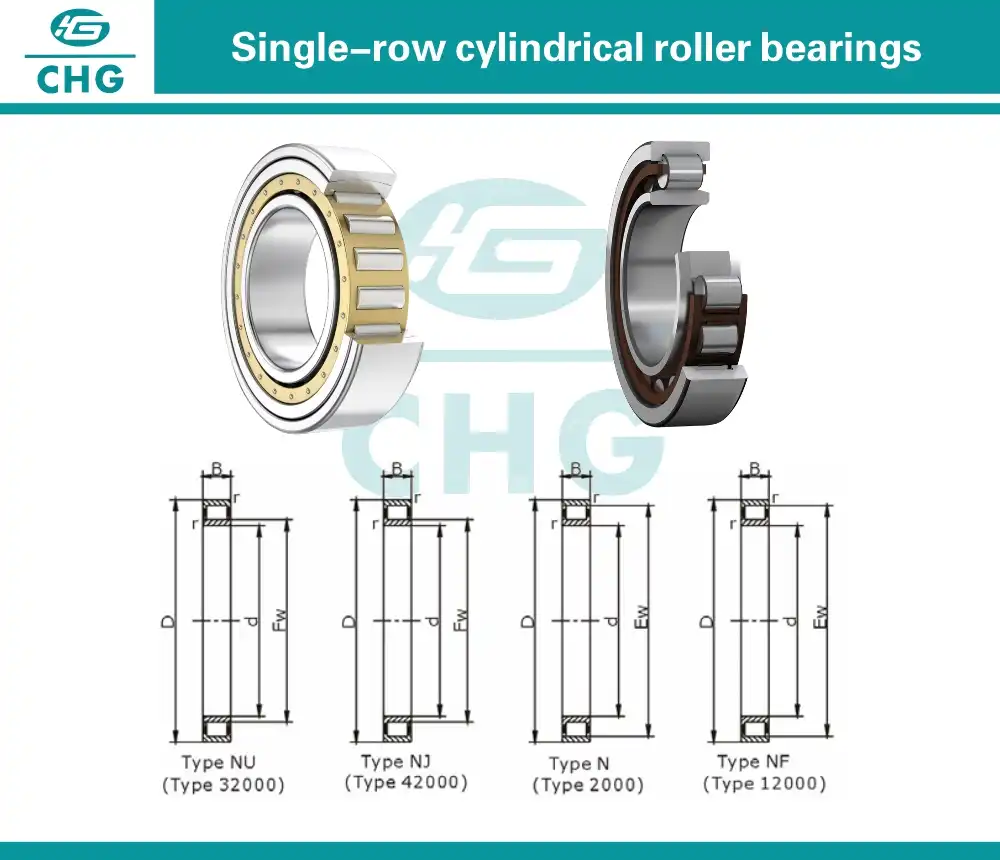

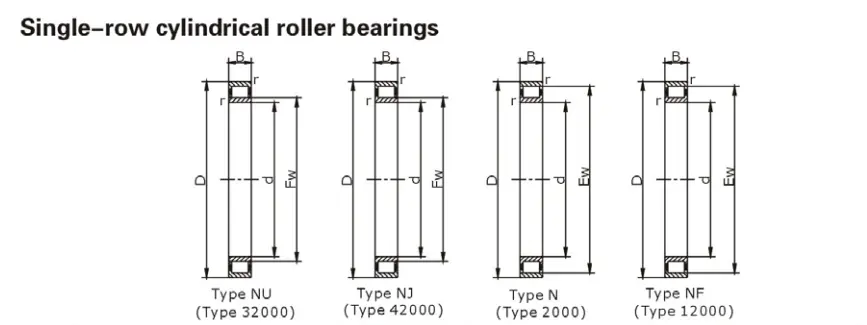

2. Series Type: NU, NJ, N, NF series cylindrical roller bearing.

3. Advantages:The single-row cylindrical roller bearing is one separable type bearing. Generally, a single-row cylindrical roller ring consists of four major components as follows: inner ring, outer ring, rollers, and cage. The rollers are typically guided by two ribs of bearing ring .

This kind of bearing is easy to assemble,disassemble and applicable for high-speed rotation cases. So, compared with a normal radial ball bearing with same size, the cylindrical roller bearing is more suitable to the condition which require to bear higher radial load and higher impact resistance.

Normally,it is not used to bear an axial load. It is required the angle between the axes of its inner and outer rings is slight, generally less than 4'. Profiling of the rollers and the raceway generatrix can reduce the inclination requirement somewhat.

We manufacture single row cylindrical roller bearings are available in several designs. The main difference is the configuration of the flanges. The most popular designs are N design bearing,NU design bearing ,NJ design bearing,NUP design bearing.

4. Size range: Inter diameter:120-1320mm

5. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

What is a Single Row Cylindrical Roller Bearing?

A Single Row Cylindrical Roller Bearing is a type of rolling-element bearing that consists of a single row of cylindrical rollers. This design allows the bearing to handle high radial loads and operate at high speeds while minimizing friction and wear. The cylindrical rollers in this bearing are aligned parallel to the axis of rotation, providing a larger contact area with the raceways compared to ball bearings. This results in a bearing that is more efficient in supporting heavy loads and enduring demanding conditions.

Why Choose CHG Bearing for Single Row Cylindrical Roller Bearings?

Customization and Solutions: We provide tailored solutions to meet the specific needs of various working conditions, ensuring that our bearings perform optimally in your unique applications.

Industry Experience: With over 30 years in the industry, we have a proven track record of collaborating with large companies and handling complex bearing requirements.

For more information or to discuss your specific needs, feel free to contact us at sale@chg-bearing.com.

Technical Specifications

| Specification | Details |

|---|---|

| Type | Single Row Cylindrical Roller Bearing |

| Inner Diameter | Customizable from 90 mm to 1500 mm |

| Outer Diameter | Customizable from 120 mm to 1900 mm |

| Width | Customizable from 20 mm to 300 mm |

| Material | High-quality Chrome Steel or Stainless Steel |

| Load Capacity | High radial load capacity, specific to the design |

| Temperature Range | -40°C to +150°C |

| Lubrication | Grease or Oil, customizable |

| Seals | Open, Shielded, or Sealed |

Benefits of Single Row Cylindrical Roller Bearings

High Load Capacity: These bearings are designed to support heavy radial loads and withstand shock loads, making them ideal for demanding applications.

High-Speed Operation: The design minimizes friction and heat generation, enabling high-speed operation without compromising performance.

Durability: Made from high-quality materials, these bearings offer excellent wear resistance and longevity, reducing the need for frequent replacements.

Cost-Effective: Their efficiency in handling loads and speeds translates into long-term savings on maintenance and operational costs.

Applications

Single Row Cylindrical Roller Bearing is widely used in various industries, including:

- Metallurgical Industry: For large rotating equipment like blast furnaces, rolling mills, and steelmaking equipment.

- Mining Machinery: In crushers, screens, and feeders, where high load capacity and durability are essential.

- Industrial Motors and Gearboxes: Supporting high-speed and heavy-duty applications.

- Construction Equipment: In machinery that operates under harsh conditions.

Installation Guide

- Preparation: Ensure the shaft and housing are clean and free from debris.

- Alignment: Properly align the bearing with the shaft and housing to avoid misalignment.

- Insertion: Gently press the bearing into place using appropriate tools to avoid damage.

- Lubrication: Apply the recommended lubricant to the bearing before operation.

- Checking: Verify the bearing rotates smoothly without any unusual noise or resistance.

Maintenance and Care

- Regular Inspection: Check the bearing periodically for signs of wear, damage, or contamination.

- Lubrication: Maintain proper lubrication levels to ensure smooth operation and reduce friction.

- Cleaning: Keep the bearing area clean to prevent debris from causing damage.

- Replacement: Replace the bearing promptly if signs of excessive wear or damage are observed.

Our Certification

FAQ

Q: What types of lubrication are recommended? A: We offer both grease and oil lubrication options. The choice depends on your specific application and operating conditions.

Q: How can I determine the right size for my application? A: Measure the inner and outer diameters as well as the width of the bearing space. Consult with our technical support for assistance in selecting the correct size.

Q: Can CHG Bearing provide customized solutions? A: Yes, we specialize in customizing bearings to meet specific requirements, including size, material, and lubrication type.

Customer Reviews

"CHG Bearing’s Single Row Cylindrical Roller Bearing has proven to be reliable and durable. Their customization options helped us achieve the perfect fit for our high-speed machinery. Highly recommended!" — John D., Production Manager

"The quick response and delivery from CHG Bearing ensured minimal downtime for our equipment. The quality of the bearings exceeded our expectations." — Lisa M., Technical Engineer

Contact Us

For more details or to place an order, contact us at sale@chg-bearing.com. Our team is here to assist you with any questions or special requirements you may have.

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | r/min | |||||||

| d | D | B | Fw | Ew | rmin | Cr | Cor | Grease | Oil | |||

| 120 | 180 | 28 | 135 | - | 2 | 130 | 168 | NU 1024M | 32124H | 2.96 | 3400 | 4000 |

| 180 | 28 | 135 | - | 2 | 130 | 168 | NJ 1024 | 42124 | 3.09 | 3400 | 4000 | |

| 215 | 40 | - | 191.5 | 2.1 | 250 | 211 | N 224E | 2224H | 6.2 | 2400 | 3000 | |

| 215 | 40 | 143.5 | - | 2.1 | 322 | 422 | NU 224E | 32224H | 6.2 | 2400 | 3000 | |

| 215 | 40 | 143.5 | - | 2.1 | 322 | 422 | NJ 224E | 42224H | 6.2 | 2400 | 3000 | |

| 240 | 80 | 150 | - | 3 | 477 | 408 | NJ 624 | 42724 | 17.8 | 2400 | 3200 | |

| 260 | 86 | 154 | - | 3 | 632 | 868 | NU 2324E | 32624 | 23.8 | 1900 | 2400 | |

| 310 | 72 | - | 260 | 5 | 660 | 530 | N 424 | 2424 | 29 | 1900 | 2400 | |

| 310 | 72 | 170 | - | 5 | 642 | 772 | NU 424 | 32424 | 29.1 | 1900 | 2400 | |

| 310 | 72 | 170 | - | 5 | 642 | 772 | NJ 424 | 42424 | 29.1 | 1900 | 2400 | |

| 130 | 200 | 33 | 148 | - | 2 | 152 | 212 | NU 1026 | 32126 | 3.84 | 3200 | 3800 |

| 250 | 80 | 158 | - | 3 | 547 | 473 | NJ 626 | 42726 | 18.7 | 2200 | 3000 | |

| 280 | 58 | - | 243 | 4 | 515 | 410 | N 326E | 2326 | 17.8 | 1800 | 2200 | |

| 280 | 58 | 167 | - | 4 | 492 | 620 | NU 326E | 32326 | 17.9 | 1800 | 2200 | |

| 280 | 58 | 167 | - | 4 | 492 | 620 | NJ 326E | 42326 | 18.2 | 1800 | 2200 | |

| 280 | 93 | - | 243 | 4 | 770 | 685 | N 2326 | 2626 | 29 | 1800 | 2200 | |

| 280 | 93 | 167 | - | 4 | 748 | 1060 | NU 2326 | 32626 | 28.7 | 1800 | 2200 | |

| 280 | 93 | 167 | - | 4 | 748 | 1060 | NJ 2326 | 42626 | 29 | 1800 | 2200 | |

| 340 | 78 | 185 | - | 5 | 782 | 942 | NU 426 | 32426 | 41.5 | 1500 | 1900 | |

| 340 | 78 | 185 | - | 5 | 782 | 942 | NJ 426 | 42426 | 41.7 | 1500 | 1900 | |

| 140 | 190 | 24 | - | 178 | 1.5 | 126 | 190 | N1928 | - | 2 | 3200 | 3800 |

| 190 | 24 | 154 | - | 1.5 | 126 | 190 | NU1928 | - | 1.98 | 3200 | 3800 | |

| 210 | 33 | 158 | - | 1.1 | 190 | 270 | NU1028 | 32128 | 3.87 | 2400 | 3000 | |

| 250 | 68 | 169 | - | 3 | 500 | 730 | NU2228 | - | 14.7 | 2000 | 2600 | |

| 250 | 68 | 169 | - | 3 | 438 | 700 | NJ 2228 | 42528 | 17 | 2000 | 2600 | |

| 300 | 62 | - | 260 | 4 | 545 | 690 | NF 328 | 12328 | 21.8 | 1800 | 2200 | |

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | r/min | |||||||

| d | D | B | Fw | Ew | rmin | Cr | Cor | Grease | Oil | |||

| 190 | 260 | 42 | 208 | - | 2 | 239 | 216 | NU 2938 | 2032938 | 6.45 | 2000 | 2800 |

| 290 | 46 | 215 | - | 2.1 | 395 | 595 | NU1038 | 32138 | 11 | 2000 | 2800 | |

| 340 | 55 | - | 302 | 4 | 630 | 830 | N238 | 2238 | 22.9 | 1600 | 1900 | |

| 340 | 55 | 231 | - | 4 | 512 | 745 | NU 238 | 32238 | 21.6 | 1600 | 1900 | |

| 340 | 55 | 231 | - | 4 | 512 | 745 | NJ 238 | 42238 | 22 | 1600 | 1900 | |

| 340 | 92 | - | 299 | 4 | 910 | 1400 | N2238 | - | 38.6 | 1600 | 1900 | |

| 340 | 92 | 231 | - | 4 | 975 | 1570 | NU 2238 | 32538 | 38.6 | 1600 | 1900 | |

| 400 | 78 | - | 345 | 5 | 882 | 1190 | N 338 | 2338 | 50.2 | 1200 | 1500 | |

| 400 | 78 | 245 | - | 5 | 882 | 1190 | NU 338 | 32338 | 48.5 | 1200 | 1500 | |

| 200 | 310 | 51 | - | 281 | 2 | 408 | 408 | N 1040 | 42140 | 10.2 | 1900 | 2400 |

| 310 | 51 | 229 | - | 2.1 | 408 | 615 | NU 1040 | 32140 | 14.3 | 1900 | 2400 | |

| 310 | 51 | 229 | - | 2.1 | 408 | 615 | NJ 1040 | 42140 | 14.7 | 1900 | 2400 | |

| 310 | 66 | 229 | - | 3 | 560 | 925 | NU2040 | - | 18.5 | 1900 | 2400 | |

| 360 | 58 | - | 316 | 4 | 570 | 842 | N 240 | 2240 | 26.8 | 1500 | 1800 | |

| 360 | 58 | 244 | - | 4 | 570 | 842 | NU 240 | 32240 | 26.5 | 1500 | 1800 | |

| 360 | 58 | 244 | - | 4 | 570 | 842 | NJ 240 | 42240 | 27.1 | 1500 | 1800 | |

| 420 | 138 | - | 360 | 4 | 1510 | 2240 | N 2340 | 2640 | 94.5 | 1200 | 1500 | |

| 420 | 165 | 260 | - | 5 | 1730 | 2660 | NU 3340 | 3032340 | 118 | 1200 | 1500 | |

| 220 | 340 | 56 | 250 | - | 3 | 448 | 685 | NU 1044 | 32144 | 19.3 | 1800 | 2200 |

| 340 | 56 | 250 | - | 3 | 448 | 685 | NJ 1044 | 42144 | 19.6 | 1800 | 2200 | |

| 400 | 65 | - | 350 | 4 | 702 | 1050 | N 244 | 2244 | 36.7 | 1500 | 1800 | |

| 400 | 65 | 270 | - | 4 | 702 | 1050 | NU 244 | 32244 | 35 | 1500 | 1800 | |

| 400 | 65 | 270 | - | 4 | 702 | 1050 | NJ 244 | 42244 | 35.4 | 1500 | 1800 | |

| 400 | 108 | 259 | - | 4 | 1360 | 2330 | NU 2244 | 32544 | 62.2 | 1300 | 1600 | |

| 400 | 108 | 270 | - | 4 | 1360 | 2330 | NJ 2244 | 42544 | 62.2 | 1300 | 1600 | |

| 460 | 88 | 284 | - | 5 | 1080 | 1465 | NU 344 | 32344 | 75.6 | 1200 | 1500 | |

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | r/min | |||||||

| d | D | B | Fw | Ew | rmin | Cr | Cor | Grease | Oil | |||

| 220 | 460 | 145 | 284 | - | 5 | 1780 | 2620 | NU 2344 | 32644 | 114 | 1000 | 1300 |

| 230 | 350 | 70 | - | 316 | 2.1 | 856 | 610 | NF 646 | 402746 | 26 | 1500 | 1900 |

| 370 | 80 | - | 334 | 3 | 826 | 795 | N 646 | 2746 | 37 | 1400 | 1800 | |

| 240 | 360 | 37 | - | 325 | 2.1 | 388 | 392 | N 0048 | 7002148 | 14.7 | 1000 | 1400 |

| 360 | 56 | 270 | - | 3 | 470 | 745 | NU 1048 | 32148 | 20.4 | 1700 | 2000 | |

| 360 | 56 | 270 | - | 3 | 470 | 745 | NJ 1048 | 42148 | 21 | 1700 | 2000 | |

| 360 | 92 | 270 | - | 3 | 855 | 938 | NU 3248 | 3032148 | 35.5 | 1000 | 1300 | |

| 400 | 74 | 282 | - | 4 | 975 | 1500 | NU1148 | - | 39.1 | 1300 | 1600 | |

| 440 | 72 | - | 395 | 4 | 1100 | 1550 | N248 | 2248 | 50.3 | 1300 | 1600 | |

| 440 | 72 | 295 | - | 4 | 880 | 1345 | NU 248 | 32248 | 46.9 | 1300 | 1600 | |

| 440 | 72 | 295 | - | 4 | 880 | 1345 | NJ 248 | 42248 | 49.6 | 1300 | 1600 | |

| 440 | 120 | 295 | - | 4 | 1700 | 2500 | NU2248E | - | 84.1 | 1200 | 1500 | |

| 500 | 95 | 310 | - | 5 | 1290 | 1810 | NU 348 | 32348 | 97.7 | 1000 | 1300 | |

| 500 | 155 | 310 | - | 5 | 2000 | 2900 | NU2348 | - | 150 | 1000 | 1300 | |

| 250 | 380 | 50 | - | 347 | 4 | 660 | 643 | N 650 | 2750 | 19.8 | 1300 | 1700 |

| 260 | 400 | 44 | - | 360 | 3 | 552 | 603 | N 0052 | 7002152 | 22.7 | 1500 | 1800 |

| 400 | 65 | - | 364 | 4 | 621 | 630 | N 1052 | 2152 | 30.8 | 1500 | 1800 | |

| 400 | 65 | 296 | - | 4 | 592 | 932 | NU 1052 | 32152 | 29.5 | 1500 | 1800 | |

| 440 | 144 | 298.5 | - | 4 | 2300 | 3500 | NU3152E | - | 92.9 | 1200 | 1500 | |

| 480 | 80 | 320 | - | 5 | 1100 | 1580 | NU 252 | 32252 | 67.2 | 1100 | 1400 | |

| 280 | 350 | 33 | 299 | - | 2.1 | 210 | 440 | NJ1856 | - | 7.31 | 1500 | 1800 |

| 360 | 30 | - | 339 | 4 | 325 | 605 | N1856X3 | - | 7.76 | 1400 | 1700 | |

| 380 | 46 | - | 354 | 2.1 | 495 | 875 | N1956 | - | 15.3 | 1400 | 1700 | |

| 380 | 46 | 306 | - | 3 | 450 | 785 | NU1956 | - | 14.5 | 1400 | 1700 | |

| 420 | 65 | - | 384 | 4 | 840 | 1500 | N1056 | 2156 | 33 | 1400 | 1700 | |

| 420 | 82 | 316 | - | 4 | 1050 | 1900 | NU2056 | - | 41.8 | 1400 | 1700 | |

| 420 | 65 | 316 | - | 4 | 600 | 965 | NU 1056 | 32156 | 33.4 | 1400 | 1700 | |

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | r/min | |||||||

| d | D | B | Fw | Ew | rmin | Cr | Cor | Grease | Oil | |||

| 300 | 420 | 56 | 332 | - | 3 | 500 | 850 | NU1960MA | - | 23.4 | 1200 | 1500 |

| 460 | 74 | 340 | - | 4 | 880 | 1470 | NU 1060 | 32160 | 44.4 | 1200 | 1500 | |

| 460 | 74 | 340 | - | 4 | 880 | 1470 | NJ 1060 | 42160 | 45.1 | 1200 | 1500 | |

| 460 | 118 | 340 | - | 4 | 1690 | 1340 | NU 3060 | 3032160 | 72 | 1060 | 1340 | |

| 500 | 160 | 358 | - | 5 | 2000 | 4000 | NU3160 | - | 135 | 1000 | 1300 | |

| 540 | 85 | 364 | - | 5 | 1350 | 1290 | NU 260 | 32260 | 87.2 | 1000 | 1300 | |

| 620 | 109 | 385 | - | 7.5 | 2010 | 1840 | NU 360 | 32360 | 166 | 900 | 1100 | |

| 320 | 400 | 38 | - | 380 | 2.1 | 340 | 680 | N1864 | - | 10.7 | 1100 | 1400 |

| 440 | 72 | - | 408 | 3 | 735 | 1520 | N2964M | - | 33.7 | 1200 | 1500 | |

| 480 | 74 | 360 | - | 4 | 890 | 1520 | NU 1064 | 32164 | 47 | 1100 | 1400 | |

| 480 | 74 | 360 | - | 4 | 890 | 1520 | NJ 1064 | 42164 | 47 | 1100 | 1400 | |

| 480 | 95 | 360 | - | 4 | 1540 | 2800 | NU2064 | - | 61 | 1100 | 1400 | |

| 340 | 520 | 57 | - | 470 | 4 | 995 | 935 | N0068 | 7002168 | 45.5 | 950 | 1200 |

| 520 | 82 | 385 | - | 5 | 1200 | 2000 | NU1068 | 32168 | 62.6 | 955 | 1200 | |

| 520 | 106 | 385 | - | 5 | 1950 | 3730 | NU2068 | - | 84.6 | 955 | 1200 | |

| 530 | 133.5 | - | 476 | 4 | 1660 | 1810 | N 668 | 2768 | 117 | 880 | 1100 | |

| 360 | 540 | 82 | 405 | - | 5 | 1200 | 2050 | NU1072 | 32172 | 65.6 | 900 | 1100 |

| 650 | 170 | 435 | - | 6 | 3500 | 6050 | NU 2272 | 32572 | 263 | 850 | 1000 | |

| 750 | 224 | 465 | - | 7.5 | 5010 | 8740 | NU 2372 | 32672 | 485 | 850 | 1000 | |

| 380 | 480 | 60 | - | 451 | 2.1 | 647 | 756 | N 2876 | 2002876 | 24.6 | 900 | 1100 |

| 560 | 82 | 425 | - | 5 | 1250 | 2150 | NU1076 | 32176 | 68.5 | 900 | 1100 | |

| 680 | 177 | 451 | - | 6 | 3860 | 6410 | NU2276 | - | 282 | 700 | 900 | |

| 400 | 540 | 65 | 438 | - | 4 | 785 | 988 | NU 1980 | 1032980 | 42.7 | 950 | 1150 |

| 600 | 90 | 450 | - | 5 | 1420 | 2480 | NU 1080 | 32180 | 88.8 | 900 | 1100 | |

| 600 | 148 | - | 554 | 5 | 2400 | 4400 | N3080 | - | 151 | 700 | 900 | |

| 600 | 148 | 458 | - | 5 | 2150 | 4450 | NU 3080 | 3032180 | 145 | 700 | 900 | |

| 650 | 145 | - | 585 | 6 | 2830 | 3030 | N 2180 | 2002780 | 190 | 700 | 900 | |

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | r/min | |||||||

| d | D | B | Fw | Ew | rmin | Cr | Cor | Grease | Oil | |||

| 420 | 620 | 90 | 470 | - | 5 | - | - | NU1084 | 32184 | - | 700 | 900 |

| 440 | 546 | 46 | 468 | - | 2.5 | 413 | 476 | NU 688 | 32788 | 26.5 | 730 | 920 |

| 650 | 94 | 493 | - | 6 | 1600 | 2850 | NU1088 | 32188 | 106 | 700 | 900 | |

| 720 | 122 | - | 648 | 6 | 2320 | 2220 | N 1188 | 1002788 | 191 | 510 | 620 | |

| 460 | 620 | 95 | - | 580 | 4 | 1340 | 2930 | N 2992 | 2002992 | 82.4 | 500 | 630 |

| 620 | 95 | 504 | - | 4 | 1340 | 2060 | NU 2992 | 2032992 | 84 | 500 | 630 | |

| 760 | 240 | 529.3 | - | 7.5 | 5210 | 9690 | NU3192 | - | 419 | 400 | 500 | |

| 500 | 670 | 100 | 543 | - | 5 | 2000 | 2410 | NU 29/500 | 20329/500 | 99.5 | 560 | 710 |

| 720 | 100 | 556 | - | 6 | 2050 | 3710 | NU10/500 | - | 137 | 400 | 500 | |

| 530 | 710 | 106 | 578 | - | 5 | 1770 | 3900 | NU 29/530 | 20329/530 | 123 | 400 | 500 |

| 560 | 820 | 115 | 625 | - | 6 | 2550 | 4700 | NU10/560 | - | 205 | 380 | 460 |

| 600 | 730 | 60 | 635 | - | 3 | 830 | 1950 | NU18/600 | - | 49.2 | 400 | 500 |

| 800 | 90 | - | 750 | 5 | 1210 | 2140 | N19/600 | - | 115 | 380 | 460 | |

| 800 | 90 | 649 | - | 5 | 1950 | 2650 | NU19/600 | - | 122 | 380 | 460 | |

| 800 | 118 | 650 | - | 5 | 2430 | 5110 | NUP29/600 | - | 173 | 380 | 460 | |

| 630 | 850 | 100 | 688 | - | 6 | 1850 | 3900 | NU 19/630 | 10329/630 | 160 | 280 | 360 |

| 850 | 128 | 685 | - | 6 | 3050 | 4260 | NU 29/630 | 20329/630 | 206 | 280 | 360 | |

| 670 | 820 | 69 | 708 | - | 4 | 1230 | 2830 | NJ18/670 | - | 78.4 | 280 | 360 |

| 700 | 930 | 160 | 760 | - | 6 | 3200 | 4580 | NU 6/700 | 327/700 | 295 | 310 | 390 |

| 710 | 870 | 74 | 750 | - | 4 | 1300 | 3000 | NJ18/710 | - | 94.5 | 310 | 390 |

| 950 | 106 | - | 890 | 6 | 2300 | 5000 | N 19/710 | 10023/710 | 205 | 220 | 300 | |

| 950 | 106 | 775 | - | 6 | 2300 | 5000 | NU 19/710 | 10329/710 | 207 | 220 | 300 | |

| 800 | 1060 | 115 | 870 | - | 6 | 2760 | 6150 | NU 19/800 | 10329/800 | 280 | 200 | 240 |

| 840 | 1040 | 125 | - | 985 | 3 | 2530 | 5290 | N 6/840 | 27/840 | 240 | 200 | 240 |

| 850 | 1120 | 118 | 925 | - | 6 | 2780 | 6350 | NU 19/850 | 10329/850 | 320 | 170 | 220 |

| 1120 | 118 | - | 1059 | 6 | 3318 | 7156 | NF19/850 | - | 282 | 170 | 220 | |

| 1120 | 155 | 917 | - | 6 | 4450 | 10500 | NU 29/850 | 20329/850 | 425 | 170 | 220 | |

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | r/min | |||||||

| d | D | B | Fw | Ew | rmin | Cr | Cor | Grease | Oil | |||

| 870 | 1050 | 90 | 912 | - | 5 | 2140 | 5280 | NJ18/870 | - | 152 | 170 | 220 |

| 880 | 950 | 60 | 898 | - | 2.5 | 775 | 2900 | NU18/880 | - | 36.8 | 200 | 240 |

| 950 | 60 | 898 | - | 2.5 | 800 | 3000 | NUP18/880 | - | 39.4 | 200 | 240 | |

| 950 | 1250 | 175 | 1024 | - | 7.5 | 5270 | 9120 | NU 29/950 | 20329/950 | 563 | 140 | 170 |

| 1250 | 224 | - | 1170 | 7.5 | 6780 | 10500 | N 39/950 | 30029/950 | 745 | 140 | 170 | |

| 1000 | 1210 | 92 | - | 1155 | 5 | 1350 | 2760 | N18/1000 | - | 206 | 120 | 150 |

| 1220 | 100 | 1053 | - | 6 | 2376 | 5895 | NU 18/1000 | 10328/1000 | 265 | 120 | 150 | |

| 1220 | 128 | 1058 | - | 6 | 3200 | 8850 | NU28/1000 | - | 319 | 120 | 150 | |

| 1220 | 128 | - | 1165 | 6 | 3680 | 10020 | NF28/1000 | - | 350 | 120 | 150 | |

| 1220 | 128 | 1053 | - | 6 | 2376 | 5896 | NUP 18/1000 | 10928/1000 | 287 | 120 | 150 | |

| 1320 | 185 | 1082 | - | 7.5 | 6336 | 15570 | NU 29/1000 | 20329/1000 | 700 | 110 | 140 | |

| 1060 | 1280 | 165 | 1120 | 6 | 3750 | 11300 | NU38/1060 | - | 427 | 120 | 150 | |

| 1280 | 128 | - | 1225 | 6 | 3222 | 9360 | N 28/1060 | 20028/1060 | 360 | 110 | 140 | |

| 1400 | 150 | 1162 | - | 7.5 | 4500 | 10000 | NU 19/1060 | 10329/1060 | 683 | 120 | 150 | |

| 1400 | 195 | 1142 | - | 7.5 | 6489 | 15570 | NU 29/1060 | 20329/1060 | 870 | 120 | 150 | |

| 1400 | 250 | 1146 | - | 7.5 | 8217 | 21600 | NU 39/1060 | 30329/1060 | 1070 | 120 | 150 | |

| 1500 | 325 | - | 1390 | 9.5 | 11700 | 29250 | N 30/1060 | 30021/1060 | 1900 | - | - | |

| 1120 | 1360 | 106 | 1182 | - | 6 | 3069 | 7785 | NJ 18/1120 | 10428/1120 | 335 | - | - |

| 1360 | 180 | 1180 | 6 | 5700 | 17300 | NU38/1120 | - | 547 | - | - | ||

| 1580 | 345 | 1231 | - | 9.5 | 14130 | 35100 | NU 30/1120 | 30321/1120 | 2150 | - | - | |

| 1180 | 1420 | 106 | 1245 | - | 6 | 3250 | 8500 | NU18/1180 | - | 328 | - | - |

| 1420 | 106 | 1245 | - | 6 | 2727 | 7020 | NJ 18/1180 | 10428/1180 | 350 | - | - | |

| 1540 | 206 | 1258 | - | 7.5 | 8073 | 19440 | NU 29/1180 | 20329/1180 | 1050 | - | - | |

| 1540 | 272 | - | 1466 | 7.5 | 10080 | 26100 | N 39/1180 | 30029/1180 | 1400 | - | - | |

| 1250 | 1750 | 290 | - | 1635 | 9.5 | 11520 | 27450 | N 20/1250 | 20021/1250 | 2320 | - | - |

| 1630 | 170 | 1350 | 7.5 | 6300 | 15400 | NU19/1250 | - | 952 | - | - | ||

| 1320 | 1600 | 122 | 1395 | - | 6 | 34200 | 9000 | NU 18/1320 | 10328/1320 | 530 | - | - |