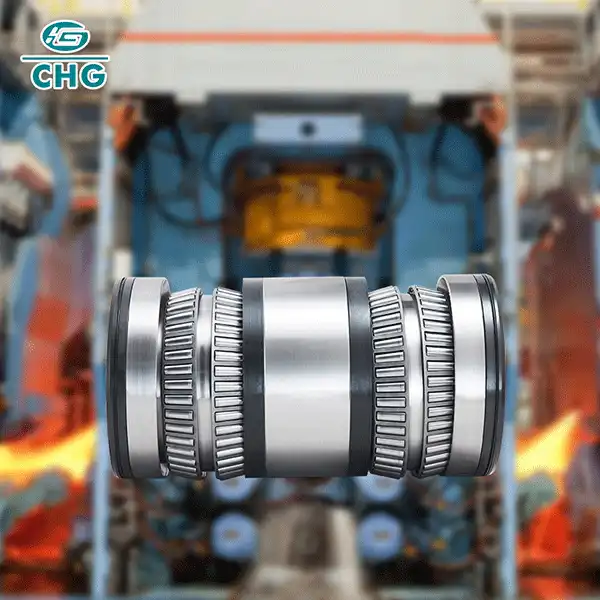

Are Sealed Tapered Roller Bearings More Durable than Open Bearings?

When it comes to industrial machinery reliability, bearing selection plays a crucial role in determining operational efficiency and maintenance costs. Among various bearing types, tapered roller bearings stand out for their ability to handle combined loads (both radial and axial). A common question among engineers and maintenance professionals is whether sealed tapered roller bearings offer superior durability compared to open designs. This article analyzes sealed versus open tapered roller bearings, examining their design features, performance characteristics, and suitability for different industrial applications.

What are the key advantages of Sealed Tapered Roller Bearings over standard designs?

Enhanced Contamination Protection

Sealed Tapered Roller Bearings provide significantly improved protection against environmental contaminants compared to open designs. In industrial settings, machinery is often exposed to harsh environments containing dust, moisture, and various particulates that can infiltrate bearings, causing accelerated wear and potential failure. The sealing mechanisms create an effective barrier against these contaminants.

Modern Sealed Tapered Roller Bearings utilize advanced seal designs, including labyrinth seals, contact seals, and multi-stage sealing systems. These sealing solutions maintain effectiveness even under challenging conditions, such as high-speed operations or environments with fine particulate matter. Industrial applications in mining, cement production, and agricultural equipment have reported maintenance interval extensions of up to 300% after switching to Sealed Tapered Roller Bearings.

Improved Lubrication Retention

Sealed Tapered Roller Bearings offer superior ability to retain lubricant. Open bearing designs experience lubricant loss through leakage, displacement, or evaporation, particularly in high-temperature or high-speed applications. This requires frequent relubrication. In contrast, sealed designs create an enclosed environment that significantly reduces lubricant loss.

The sealed design ensures that lubricant remains between the rolling elements and raceways, preventing metal-to-metal contact and reducing friction and wear. Many Sealed Tapered Roller Bearings are pre-lubricated during manufacturing with high-quality greases formulated for specific applications. Studies show that properly sealed and lubricated tapered roller bearings can maintain effective lubrication up to five times longer than open designs in comparable applications.

Extended Service Life and Reduced Maintenance

The combination of contamination protection and improved lubrication retention translates directly into extended service life for Sealed Tapered Roller Bearings. Industrial machinery operating in challenging environments frequently suffers from premature bearing failures with open designs. By contrast, sealed designs consistently demonstrate longer operational lifespans under identical conditions.

Maintenance requirements are substantially reduced with Sealed Tapered Roller Bearings. Many designs are marketed as "lubricated for life," eliminating the need for periodic relubrication in certain applications. This reduces direct maintenance costs and minimizes costly production downtime. Manufacturing facilities implementing Sealed Tapered Roller Bearings in critical equipment have reported maintenance cost reductions of 25-40% compared to open bearing designs.

How do Sealed Tapered Roller Bearings perform in extreme working conditions?

Performance in High-Temperature Environments

Modern Sealed Tapered Roller Bearings incorporate features specifically engineered to withstand high-temperature environments. Advanced designs utilize temperature-resistant materials such as fluoroelastomers, PTFE, or specialized polymer compounds that maintain integrity at temperatures exceeding 150°C.

Premium Sealed Tapered Roller Bearings are designed with appropriate internal clearances and materials to accommodate thermal expansion without compromising functionality. Special high-temperature lubricants with enhanced oxidation resistance and thermal stability complement these designs. Field tests in steel mills and glass manufacturing have demonstrated that properly specified Sealed Tapered Roller Bearings can maintain sealing integrity at continuous operating temperatures up to 200°C.

Resistance to Water and Chemical Exposure

Sealed Tapered Roller Bearings address vulnerability to water and chemicals through specialized sealing systems designed to resist moisture or chemical infiltration, even in wash-down environments or processes where direct exposure is unavoidable.

Advanced designs utilize multiple layers of protection, often combining contact seals with secondary labyrinth designs to create redundant barriers. The materials selected for these seals resist chemical attack from common industrial substances. Food processing equipment, chemical manufacturing, and marine applications have successfully implemented Sealed Tapered Roller Bearings, resulting in significant reductions in corrosion-related failures.

Performance Under Heavy Loads and Shock Conditions

Modern Sealed Tapered Roller Bearings are engineered to provide robust sealing without compromising load-handling capabilities. The sealing systems maintain integrity even under deflection caused by heavy loads or shock impacts through flexible seal designs that accommodate slight misalignments without creating contamination pathways.

The consistent lubrication maintained within sealed bearings enhances their ability to absorb shock loads by ensuring adequate film thickness between contact surfaces. Heavy equipment applications, including construction machinery and mining vehicles, have demonstrated that properly specified Sealed Tapered Roller Bearings maintain sealing effectiveness even under severe shock loading conditions.

When should you choose Sealed Tapered Roller Bearings over open designs?

Cost-Benefit Analysis for Different Applications

The initial acquisition cost of Sealed Tapered Roller Bearings typically exceeds comparable open bearings by 20-40%. However, analysis must extend beyond purchase price to capture total ownership cost.

In environments with high contamination risks, such as mining or agricultural equipment, the extended service life provided by sealed designs frequently justifies the higher initial investment. Maintenance cost reductions can be particularly significant for difficult-to-access equipment. Organizations implementing Sealed Tapered Roller Bearings in appropriate applications have documented return-on-investment periods typically ranging from 6-18 months.

Installation and Maintenance Considerations

Installation of Sealed Tapered Roller Bearings demands strict adherence to manufacturer guidelines to prevent damage to sealing components. Most arrive pre-lubricated with precisely measured lubricant optimized for the intended application, eliminating the need for lubricant addition during installation.

Maintenance programs must be adjusted when transitioning to sealed designs. While open bearings require regular relubrication, many sealed designs eliminate this requirement. However, condition monitoring becomes increasingly important to detect potential issues before failure occurs. Organizations that have successfully implemented Sealed Tapered Roller Bearings typically report 50-70% reductions in routine maintenance hours.

Industry-Specific Applications and Success Stories

Different industries have unique requirements influencing the suitability of Sealed Tapered Roller Bearings. The food and beverage industry benefits from sealed designs that prevent lubricant contamination of products while protecting bearings from wash-down procedures.

The mining sector represents another industry where sealed bearings deliver exceptional value. Several mining operations have documented maintenance interval extensions from quarterly to annual after transitioning to Sealed Tapered Roller Bearings. Automotive manufacturing has similarly embraced sealed designs for assembly line equipment, where consistent operation and minimal maintenance are essential.

Conclusion

Sealed Tapered Roller Bearings demonstrably offer superior durability compared to open designs in most industrial applications, particularly those involving contamination risks or maintenance challenges. Their enhanced protection against environmental factors, improved lubrication retention, and reduced maintenance requirements typically outweigh their higher initial cost through extended service life and improved reliability. While application-specific factors must always be considered, the evidence strongly supports the selection of sealed designs for operations prioritizing equipment longevity and reduced total ownership costs.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A. and Kotzalas, M.N. (2023). Essential Concepts of Bearing Technology: Rolling Bearing Analysis. CRC Press, Boca Raton.

2. Zhang, L., Ren, Q., and Wang, J. (2022). "Comparative Analysis of Sealed and Open Tapered Roller Bearings in Heavy Equipment Applications." Journal of Tribology and Lubrication Technology, Vol. 44, pp. 327-341.

3. Smithson, R.K. and Johnson, P.L. (2023). "Environmental Protection Strategies for Industrial Bearings: A Case Study in Mining Applications." International Journal of Industrial Engineering, Vol. 18, Issue 3, pp. 115-129.

4. Nakajima, H. and Wilson, T.D. (2021). Bearing Tribology: Principles and Applications. Springer Industrial Engineering Series, Berlin.

5. Chen, W., Li, X., and Thompson, R.V. (2023). "Cost-Benefit Analysis of Sealed Bearing Technology in Process Manufacturing." Industrial Maintenance & Plant Operation Journal, Vol. 29, pp. 214-228.

6. Antonescu, P. and Schmidt, B. (2022). "Performance Evaluation of Sealing Systems in Tapered Roller Bearings Under Extreme Operating Conditions." Tribology International, Vol. 67, pp. 492-507.